Additive Manufacturing Sees Rapid Adoption

Since the 2009 recession, the additive manufacturing systems market for industrial applications has seen an impressive recovery, reaching a new milestone in overall revenue for machinery and services.

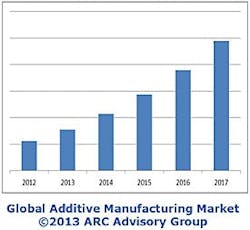

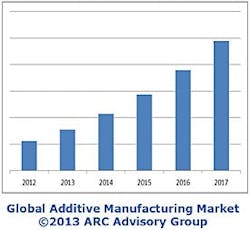

The market saw shipments exceed $1 billion in 2012, according to ARC Advisory Group global market research study. The study shows new acquisitions, channel expansion and new startup companies are contributing to the market's growth as they begin the early adoption stages of additive manufacturing.

The synergy of digital modeling in combination of additive manufacturing appears to be one of the most influential processes responsible for the rapid adoption and is predicted to increase growth rates into the double-digits over the next five years.

Additive manufacturing offers manufacturers a competitive advantage by allowing them to overcome traditional challenges during the design process. Prior development constraints prevented manufacturers from designing cost-effective, complex structures.

"Due to the geometric freedom the technology affords and the absence of a penalty for designing more complex parts, additive manufacturing should create a powerful incentive for innovation," said Scott Evans, research analyst for ARC and principal author of ARC's "Additive Manufacturing Systems Global Market Research Study."

To learn how additive technologies are being used in the plastic build materials market as well as its growth in the Asian market, read the full article on ARC's site.