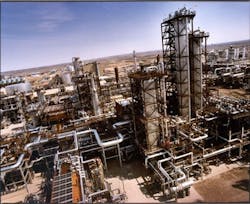

Shell Canada Site Receives 2011 HART Plant of the Year Award

Shell Canada's Scotford Upgrader near Fort Saskatchewan, Alberta, is the latest recipient of the HART Plant of the Year Award, which showcases end users demonstrating creativity in the application of HART Communication.

Shell's Scotford Upgrader used HART Communication to facilitate device configuration, loop testing, startup checks, valve tuning, safety device SIL ratings, and real-time centralized device status and diagnostics in a 100,000 barrel-per-day (bpd) expansion to its existing 155,000 bpd capacity Scotford facility.

Shell engineers used the full capabilities and advantages of HART Communication to facilitate device configuration, loop testing, startup checks, valve tuning, safety device SIL ratings, and real-time centralized device status and diagnostics in a 100,000 barrel-per-day (bpd) expansion to its existing 155,000 bpd capacity Scotford facility, noted the HART Communication Foundation, which selected the plant for the 2011 award. The result was a safe and efficient startup, continued safe and reliable plant operation, real-time daily instrument troubleshooting, and not only preventable but also predictive ongoing maintenance.

"Our decision to broaden the application of HART technology beyond the use of handheld device configuration saved us time and money in all phases of this project," said Andy Bahniuk, Shell instrumentation technologist. "With all the HART data available in one centralized control room, staff in operations, maintenance and instrumentation had ready access to this valuable information, which ensured total confidence for both the operators and engineers that all devices were functioning properly."

According to Bahniuk, HART Communication helped the Shell facility to realize benefits and savings throughout the project and the plant's ongoing operation:

- Fast and safe device configuration, programming and commissioning of 1,200 HART devices from 26 vendors.

- Loop function testing and process variable simulation performed in 30% of the time normally required, without potential for human error.

- Simulation of critical and complex safety narratives involving more than 15 inputs and multiple outputs for more than 50% in overall time saving.

- The elimination of the need to add external hardware to more than 700 smart valve positioners, saving about $2,000 per valve.

- The ability to monitor secondary transmitter temperature variables remotely to improve efficiency in preventive maintenance on heated instrument boxes, saving more than $200,000 per year.

- Re-calibration, parameter checks and device diagnostics performed from a central control room rather than at each individual transmitter location, which provides savings of $100,000 annually.

One of the biggest benefits was that they did not have to do any special device testing for interoperability, Bahniuk said. "All our HART devices were plug-and-play, connected through an asset management system," he said. "We are using the ability to open a virtual window and unlock all the power of HART Communication for any type of measurement device supplied by all of our manufacturers."

The Scotford Upgrader, operated by Shell Canada as part of a joint-venture project between Shell Canada, Chevron Canada and Marathon Oil Sands, uses hydrogen-addition technology to upgrade the high-viscosity "extra heavy" crude oil (called bitumen) from the Muskeg River Mine into a wide range of synthetic crude oils. Shell Scotford is home to three distinct operating facilities: Upgrader, with 255,000 bpd total capacity (since the 2011 expansion); Chemicals, which manufactures 530 kt/yr of styrene monomer and 604 kt/yr of ethylene glycol; and Refinery, with a 100,000 bpd capacity. Total staff on site is more than 1,300 (plus contractors).

The HART Plant of the Year award is given annually to recognize the people, companies and plant sites around the world using the advanced capabilities of HART Communication in real-time applications to improve operations, lower costs and increase availability.