Rocket Launches Maxon Motors Into Outer Space

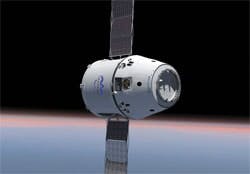

On May 22, the SpaceX Falcon 9 rocket was launched into outer space with a mission to rotate the Dragon spacecraft solar arrays toward the sun to supply power to itself. But this task wouldn't have been possible without the help of Maxon Motor high-precision brushless motors.

SpaceX, located in Hawthorne, Calif. launched the first ever private cargo capsule from the Cape Canaveral Air Force Station in Florida. No other private company has created a spacecraft and launch system combination that could successfully orbit the Earth and return safely.

As the 4.4 meter Dragon navigated towards the International Space Station (ISS), the brushless motors were used to position the solar arrays, open the instrument bay door to access control equipment and lock down a fixture that let the space craft be navigated by the ISS's 17.6 meter robotic arm.

Three days later, Astronaut Donald Pettit used the robotic arm to maneuver the Dragon and guide the spacecraft to the docking point on the ISS.

On May 31, the capsule disengaged from the ISS and slowly descended by parachute into the Pacific Ocean near the California coast. The capsule brought back 1,455 lb. of material from the ISS.

The Dragon is currently the only option NASA has to transport large amounts of material to Earth from the ISS since it is no longer participating in its space shuttle program. NASA signed a 12-flight contract with SpaceX and plans to send seven astronauts to the ISS within the next few years.