Aaron Hand is the managing editor for Control Design and for Industrial Networking. Email him at [email protected] or check out his Google+ profile.In business for more than 57 years, Pearson Packaging Systems has changed its program in the face of a shifting market, adapting to the changing needs of its customers. The secondary packaging equipment manufacturer used to provide discrete equipment; now it's gone the way of integrated solutions. Along the way, it standardized on controls, software and more to make things easier for itself and its customers.

"A lot of customers used to have large engineering organizations, and they would specify what products they needed," says Michael Senske, president and CEO of Pearson Packaging. "Now, they tell us here's what we're trying to accomplish, and the throughput we need, and they're relying on us to provide the engineering."

Business began in 1955 as R.A. Pearson, the company launched by "Lefty" Pearson to sell his first automatic beverage carrier erector. By 1960, Pearson had expanded his line of machines to include the Autobox case erector for six-pack products and then tray forming for soft drink cans. Known since 2000 as Pearson Packaging Systems, the company provides secondary packaging solutions that use robotics, case packers, case erectors, bag inserters, uncuffers and case sealers.

The technology certainly has changed over the years. "In the past, the machines were purely mechanical, relying on cam-shaft and line-shaft mechanisms," Senske says. "Now they're more electromechanical, using servo motors. They offer greater precision, speed, flexibility and reliability."

Although servos add cost up front, Senske says, the total cost of ownership is greatly reduced. "It has a big impact on sustainability, too," adds Leo Robertson, vice president of engineering for Pearson. "With servos, you use what you need, and let the others rest."

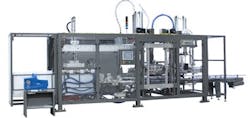

Pearson Packaging's GTL-AN1 Case-Tray Packer is a fully automatic pick-and-place case or tray forming, packing and sealing system. It can be changed over to different case sizes and pack patterns in less than 10 minutes.Over time the company's machines also shifted from 100% pushbutton-operated to almost every machine now operating through an HMI. They have the ability to be connected to each other and to an MES, a function that is increasingly in demand, Senske notes.

Senske has been with the company for about 15 years. It was when he took over as president and CEO in 2003 that Pearson also began a shift to Lean Manufacturing principles and various modes of standardization.

The machine builder has focused on designing more modular machines, standardizing code, and standardizing interfaces, Robertson notes. "This is our biggest selling point," he says. "It's why you'd buy a machine from us."

Standardizing software included a switch in 2007 to Packaging Machinery Language (PackML), a software methodology that creates data standardization across all of Pearson's machines. To learn more about Pearson's approach to PackML, see "The Case for PackML."

"If it's all PackML-compliant, you can use the same code to get data out of the machine," Senske says. "We use that code on every machine. It doesn't take us as long to deliver the equipment; it's easier to service in the field; there's a standardized way we're programming the equipment."

Standardization — PackML and otherwise — even applies to recent acquisitions Pearson has made. Pearson acquired Goodman Packaging Equipment, based in the Chicago area, in late 2008, incorporating its gantry top-load case packing equipment into its own line. Just in October, Pearson acquired Moen Industries, a Los Angeles-based manufacturer of packaging equipment and corrugated packaging designs.

In both cases, Pearson is working to bring production together with its own manufacturing. Manufacturing will be combined, and Pearson will bring Goodman and Moen lines into line with Pearson standards.

"We're not just buying them and operating them independently," Senske says. "We're moving manufacturing and assembly to Spokane, although we do retain skilled employees in the remote locations."

Speaking when the Moen acquisition was brand new, Pearson pointed to plans to apply PackML to the Moen machines. "That will allow us to integrate the machines easier," he says.

Robertson adds that modularization efforts will be a part of the melding process of the companies. "As we go to integrate the Moen product line, we'll use our own building blocks," he says.

"As time goes on, we'll apply our technology on the new machines. Then we'll be able to integrate them as part of a larger line," Senske says. "We still will write to customer specifications, but it will happen less and less."

Pearson usually finds that its standard control set is sufficient as well. "We're a complete Rockwell shop," Senske says.

In fact, Rockwell was instrumental in helping Pearson make its move to PackML, which came at a time when Rockwell was incorporating the standard into its Power Programming template.

Pearson also worked closely with Rockwell as the supplier developed its linear servo drive. This has been a major shift away from having to transfer rotary motion into linear motion. "Our old servo-driven system took 25–30 parts to drive the linear motion," Senske says. "This has five parts."

Not only is the motion fast, it's easier to convert the motion, Robertson adds. "It's not just high speed. The speed becomes highly scalable. If production drops in half, we can drop the speed in half. The wear on the machines is also cut in half."