Robots aren’t always given a favorable representation in pop culture. In Stanley Kubrick’s 1968 movie, “2001: A Space Odyssey,” homicidal supercomputer HAL 9000 demonstrates how a robot could conspire against its human colleagues. Thankfully, industrial robots aren’t quite as menacing.

Pop culture aside, robots don’t disappoint. After their first industrial robot installation, manufacturers come back time and time again to add further automation to their factories. Given that robots boost productivity, profitability and quality, it’s no surprise they are rife.

Unfortunately, small-to-medium sized manufacturers are often unwilling to invest in that very first robot; after all, they are hardly inexpensive. Thankfully, taking the automation plunge doesn’t have to be a worrisome process.

Choose your machine

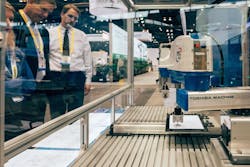

First things first: what do you want your robot to do? The desired application will determine which kind of robot is required. A SCARA robot, for instance, would be most suited for compact pick-and-place operations; whereas palletizing applications may require a six-axis machine that boasts a heavy payload (Figure 1).

Figure 1: A SCARA robot would be most suited for compact pick-and-place operations.

That said, several factors should be contemplated beyond robot type. They include the operation, payload, number of axes, reach, accuracy, cycle time and inertia. The ingress-protection (IP) rating, a metric used to define the sealing effectiveness of electrical enclosures against foreign bodies like dirt and moisture, should also be taken into account. Careful calculation of these nine parameters should be the first step of any robot investment.

It may be time-consuming, but collecting this data accurately will streamline your search for the best machine. This approach is preferable to relying on estimations, which can have disastrous results. A common mistake is failing to take end-of-arm tooling (EOAT) into the equation when determining a robot’s payload. Grippers, drills and soldering equipment can add significant weight to a robot, with the potential to push the load over the machine’s maximum lifting capacity. Suddenly, poor calculations mean that you’re left with a machine that is too feeble to fulfill its role.

Time to buy

Similarly, budgets shouldn’t be estimated. Robot investments often go far beyond the initial price tag. As well as the purchasing cost, factories may need to create a segregated work cell or buy additional power units before a robot can be deployed, not to mention variable expenditures, such as labor, energy, materials and ongoing maintenance, that are required to operate the robot long-term.

In fact, when investigating the true cost of robotics, manufacturers should budget for three times the robot’s price tag, according to a report by the Boston Consulting Group.

Ready to program

Parting with your cash isn’t necessarily the most daunting part of a robot investment, however. Instead, a common objection from manufacturers is unfamiliarity with programming languages. While installing a robot usually isn’t as simple as plug-and-play, most don’t require a huge amount of programming knowledge either.

Powerful but simple simulation tools with off-line programming function can be beneficial. However, it is also vital to decide who’ll be responsible for maintaining the robot and ensuring they’re trained.

Combined with a teach pendant—a control box for programming the motions of a robot—completing routine maintenance and adjustment becomes a pain-free process. In fact, more than 90% of robots use these tools. For technicians and engineers, this makes them an unintimidating piece of technology.

Guaranteed to perform

The cash transaction for purchasing a robot isn’t complicated. But maintaining a robot over the long term does require some expertise. When selecting your robot, you should consider whether the equipment distributor can provide expert knowledge of the equipment to guarantee its long-term performance. It’s also advantageous to establish traceable links to the original manufacturer, should something go wrong.

Typically, robot manufacturers will provide a warranty with their equipment, and reputable suppliers will, too. Be sure to fully understand the aftersales service offered by whichever distributor you choose.

Many robot manufacturers have guidelines regarding the equipment’s warranty. For instance, if the robot requires a small repair and you use an unauthorized repair partner, your guarantee may then be void.

Similarly, some robot manufacturers require that you use a predetermined service partner to keep the robot in good condition. Without evidence that you have adhered to the required servicing protocol, which could be a yearly or biannual service, you may find yourself at a financial loss if the robot breaks down.

Maintenance and repair

Like all types of industrial equipment, robots require maintenance during their lifespans. This is often covered by a warranty, or included in your distributor’s sales package. In fact, some robot distributors offer robots as a service (RaaS).

RaaS refers to the purchase of industrial robots by leasing them, as needed, rather than buying the robot outright. These offerings typically cover maintenance of the leased robot.

A large part of the savings from RaaS is through a reduction in unexpected maintenance costs. As with other servitization models, the onus and cost of repairing the leased robot falls on the robot distributor.

For many, RaaS can provide a reassuring purchasing option. Consider a small manufacturer that has purchased a robot outright. After a few months, the machine breaks down; yet it doesn’t have a warranty. The manufacturer would then need to hire repair technicians and purchase new parts in order to get the equipment back in working order, all on top of the original cost of purchasing the robot.

Maintenance and repair are two of the most complicated areas of robot investment and ownership, and they should not be overlooked by manufacturers making their first robot purchases.

ALSO READ: The keys to robot selection, safety and collaboration

About the Author

Nigel Smith

TM Robotics

Leaders relevant to this article: