Linear position sensors are devices that measure the displacement or position of an object along a straight path. There are several types of linear position sensors, each employing different technologies to achieve accurate and reliable measurements. Some position sensors can be applied in different operational applications. Many, however, cannot.

Some applications are simple and common across industries. Others, where the application is special, have been designed and developed specifically for this purpose. These should not be used in other less-suited applications. Each sensor type has its own principles of operation. Solid-state items, for instance, will normally outlast items with moving parts.

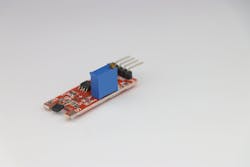

Potentiometric sensors

In terms of technology, potentiometric sensors use a resistive element and a wiper to measure linear displacement. The resistive element is usually a strip of resistive material, and the wiper is connected to the moving object.

Regarding their operation, as the object moves, the wiper changes its position along the resistive strip, causing a change in resistance. The output voltage is proportional to the position of the wiper.

Inductive sensors

Inductive position sensors utilize the principle of electromagnetic induction. These sensors consist of a coil and a core, and the coil is excited with an ac signal.

Inductive vs. magnetic position sensors

Inductive position sensing technology relies on the principle of electromagnetic induction to determine the position of an object. The non-magnetic properties of this technology can impact its performance in applications where metal filings are present in a few ways.

Interference: Metal filings can introduce interference in the electromagnetic field, affecting the accuracy of position sensing. Non-magnetic properties help minimize the impact of metal filings on the sensor's performance.

Signal distortion: Magnetic materials can alter the magnetic field generated by the sensor, leading to signal distortion. Non-magnetic properties help maintain the integrity of the signal and ensure accurate position sensing.

Sensor calibration: Non-magnetic sensors are often more stable and easier to calibrate in the presence of metallic particles. Magnetic materials may require frequent recalibration due to changes in the magnetic environment.

Reliability: Non-magnetic sensors are generally more reliable in environments with metal filings because they are less susceptible to magnetic variations. This reliability is crucial for maintaining accurate position information in industrial applications.

Consistency: The non-magnetic nature of the sensor allows for consistent performance, even in environments with varying amounts of metal filings. This consistency is important for applications that demand precision and reliability.

How does it work? When a conductive target—usually a metallic object—moves into the sensor's field, it induces eddy currents in the target, affecting the inductance of the coil. The change in inductance is used to determine the position.

Capacitive sensors

Capacitive position sensors use the principle of capacitance change. These sensors have two plates separated by a dielectric material, and the position change alters the capacitance.

In terms of operation, as the target moves, the capacitance between the plates changes. This change is measured and used to determine the position of the object.

Optical sensors

Optical position sensors utilize light to determine position. They often consist of a light source, a position-coding element, such as a coded scale or a pattern, and a photodetector.

In the operation of these sensors, the light passes through or reflects off the position-coding element, and the photodetector converts the received light into an electrical signal. The position is determined based on the pattern or code.

Magnetostrictive sensors

Magnetostrictive sensors use the magnetostrictive effect, where the length of a ferromagnetic material changes in the presence of a magnetic field.

Magnetostriction is defined as the ability of a material to experience mechanical strain when subject to a magnetic field. Magnetostriction is a phenomenon observed in all ferromagnetic materials.

How is it applied? A magnetostrictive wire is enclosed in a sensing tube, and a magnetic field is generated along the wire. The position is determined by measuring the time it takes for the magnetic field pulse to travel along the wire and interact with a position magnet.

Linear variable differential transformer

What are linear variable differential transformers (LVDTs)? They are inductive sensors that use a transformer with a movable core.

The working of a linear variable differential transformer is based on the principle of Faraday's law of electromagnetic induction that states that the net induced electromagnetic field (EMF) in the circuit is directly proportional to the rate of change of magnetic flux across the circuit, and the magnetic flux of the coil wound with wires can be changed by moving a bar magnet.

How does it work? As the core moves, it induces voltages in the transformer windings. The output voltage is proportional to the displacement of the core, providing a linear and accurate measurement.

Hall effect sensors

A Hall effect sensor uses the Hall effect, where a voltage is generated when a magnetic field is applied perpendicular to the direction of current flow in a semiconductor material.

The Hall effect is the deflection of electrons, or holes, in an n-type (p-type) semiconductor with current flowing perpendicular to a magnetic field. The deflection of these charged carriers sets up a voltage, called the Hall voltage, whose polarity depends on the effective charge of the carrier.

In operation, as the magnetic field changes with position, the Hall voltage changes, providing a signal proportional to the position of the object.

About the Author

Charles Palmer

Charles Palmer is a process control specialist and lecturer at Charles Palmer Consulting (CPC). Contact him at [email protected].