There are many control and automation installations such as SCADA or cathodic-protection systems in which ac or dc line power is not available. However with the escalating growth in wireless field networks, the issue of providing power anywhere, anytime, or more accurately all the time, becomes an increasingly critical part of the design of industrial communications systems.

Options are available to meet today's new demands and we'll discuss some things to consider when you compare the various alternate energy options.

Read Also: Wireless Sensors: Is Energy-Harvesting Possible?

SCADA Is over the Top

We've been using SCADA systems for decades, however, while they're designed to be energy-efficient, SCADA systems are much larger than what is needed for the new generation of wireless field networks. However, many of the technologies used in these applications are being scaled to the size where they're relevant to the low-energy, typically mW, demands of modern plant networks.

Wireless sensor networks (WSNs) usually require high current pulse power levels and low background currents because sensors normally have three (or more) operating modes: 1) sleep or standby, when battery power consumption is a low background current in the microamp range; 2) measurement or interrogation, when the unit requires power in the range of tens to 100 milliamps; and 3) transmission, during which time the unit might require a few hundred milliamps for up to a few milliseconds before power-down and return to an energy-saving sleep or standby status.

Depend on a Battery

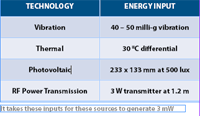

The most commonly used alternate energy source in the consumer and industrial sector is a battery. However, a battery system alone isn't likely to provide a power source that will last the lifecycle of the wireless network application without maintenance intervention. This drives the need for energy harvesting (using ambient energy to perform functions of mobile/small electronic devices) products that convert immediately available energy such as mechanical (vibration), thermal (heat), light or RF energy to milliwatts of power. With this suitable external energy source, battery life can be extended to the effective shelf life of the battery.

To meet the power and other demands of a wireless sensor energy harvesting system, it must meet some minimum criteria. The module either must have the same form, fit and function as the standard OEM wireless field-device, battery-pack module or, alternately, have an interface compatible with the device's power supply input connections. Fortunately, the ISA100.18.01 draft standard is close to completion. ISA100.18 defines the mechanical connection and pin-out for M12 A-coded connectors compliant with IEC 61076-2-101, as well as flying lead (terminal block) connections.

Sufficient capacitor capacity is required to supply the power needed for a typical transmission without drawing power from the battery. It must be hazardous area certified and, ideally, intrinsically safe, so it can be field-replaceable in any electrical classification environment without having to remove the device from service.

Note that the energy harvester doesn't provide peak power and normally is not the direct source of energy for the device, but instead is the device that keeps the battery charged. The battery in turn energizes a capacitor or supercapacitor that is the power source during the brief period when a device is awake and transmitting. When asleep, the wireless device could be consuming 0.1 mW. When transmitting, this increases by factor of 1,000 to 100 mW. Power system sizing is therefore based on the average demand of long periods charging, keeping in mind the obvious fact that the minimum power level must be greater than the sleep-mode consumption, plus losses due to energy-conversion efficiency and, of course, have a small footprint itself.

Love that Lithium

Minimizing losses and maximizing long-term energy storage over a broad range of ambient conditions are therefore criteria used to select the type of battery used in the system. Lithium-based batteries are the preferred energy storage system for many reasons, including the basic physical fact that lithium is an ideal material for battery anodes because its intrinsic negative potential exceeds that of all metals. Lithium is also the lightest non-gaseous metal. Batteries based on lithium chemistries have the highest specific energy (energy per unit weight) and energy density (energy per unit volume) of all types of power cells. Other primary cell technologies can't have cell voltage above 2 V (water dissociates into oxygen and hydrogen at potential above 2 V), so any aqueous (water-containing) cells will stop working quickly.

One of the drawbacks of lithium is that it reacts strongly with water, so only non-aqueous electrolytes can be used, and the cells must be isolated from water at all times.

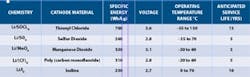

As can be seen in Table I, some lithium cells have a nominal open-circuit voltage of 3.6 V, and can operate at temperatures as low as -55 °C and as high as 150 °C.

Though not indicated in the table, manganese dioxide lithium cell internal impedance is somewhat lower than for other types of lithium-based cells, but they're well-suited to applications having relatively high continuous-current or pulse-current requirements.

Hold the Charge

Maintaining the charge in wireless sensor batteries is most often done using photovoltaic (PV) solar cells that must perform and generate electricity under a broad range of temperature and cloud-cover conditions (or dust/snow cover), and they need to produce electricity at all times of the day (from dawn to dusk). As a result, critical parameters used to evaluate solar-based systems also include temperature sensitivity and varying (low/diffuse) as well as indoor/outdoor light conditions.

It turns out that crystalline silicon has a much stronger spectral response towards the infrared region in comparison to lower wavelengths of the visible-light spectrum, and, fortunately, a significant portion of outdoor light is available. GaAs (gallium arsenide) photovoltaic cells are 10 to 100 times more expensive than other PV technologies because they have the highest potential of crystalline cells, but they nevertheless are the technology gaining traction for industrial installations.

Despite many advances being made-in-energy-harvesting technologies, we, as the team responsible for the installation and maintenance of these systems, must be aware that each of these options comes iwht issues that need consideration.These are some ideas to keep in mind when working with each of the technologies discussed in this article: Batteries are governed by directive 2006/66/EC, the "Battery directive" on batteries, accumulators, waste batteries and accumulators, which regulates manufacture and disposal of batteries oin teh European Union, and puts the onus on manufactureres incorporating such devices in their products to provide cradle-to-grave support.

Read more here.

Additional research is being done to develop dye-sensitized solar cells (DSSC), also sometimes called dye-sensitized cells (DSC), which use a photoactive dye that catches photons to excite electrons much the same way photosynthesis works. The dye injects the excited electron into titanium dioxide, which is conducted away by nanocrystalline titanium dioxide. Then chemical electrolyte in the cell closes the circuit to return the electron to the dye. The movement of the electrons through this circuit creates the harvested energy. One advantage of DSSC is that it works with similar efficiencies of about 14% conversion in both ambient (solar) and inside lighting conditions.

Work by National Instruments' (www.ni.com) Nagarajan Sridhar and Dave Freeman has shown that the energy available from PV systems can be related to illuminance (light level) incident on the cell as per two equations:

Fractional current method: Imax = 0.93 * Isc

Fractional voltage method: Vmax = 0.74 * Voc

The first equation shows the strong linearity between short circuit (Isc) and maximum power point current (Imax). The second equation relates a similar linear relationship between the open-circuit voltage (Voc) and the maximum power point voltage (Vmax) on a logarithmic scale of illuminance.

However, each individual solar cell develops very low levels of voltage and current, so manufacturers use Ohm's law to connect energy-harvesting modules in series (voltage increase) or in parallel (current increase) to achieve the desire power levels from the system.

The same Ohm's Law principles apply to thermoelectric power generators, where the voltage generated is directly proportional to the number of couples (N) and the temperature differential (dT) between the top and bottom (hot and cold) sides of the unit as per the relationship, V = 4N(af-an)dT, where an and af are the Seebeck coefficient for n and p type materials, respectively. The Seebeck coefficient is defined as the Seebeck voltage per unit temperature, and is a material property based on the fact that electrons are carriers of both electricity and heat. If a temperature gradient exists over a piece of electrically conductive wire, there is a net diffusion of electrons from the hot end toward the cold end, thereby creating an opposing electric field.

Similar principles have been used for many years in SCADA systems using thermopiles to develop the necessary voltage by putting many small thermocouples in series, and then summing all the resulting mV temperature measurements to obtain the desired voltage.

The Power of PoE and RF

Another potential source of energy—for gateways at least—is Power over Ethernet (PoE). Though not an energy-harvesting technology because PoE is 44-57 V and not the 24 V traditionally used in the automation and control space or required by the device circuitry itself, it must be converted to the appropriate voltage level. In addition, if we could scavenge power from the gateway, we could then use it as the supply for another energy-harvesting technology—RF transmission. RF can be used to transmit energy over short distances at specific frequencies.

RF power transmission systems are limited by the Friis Transmission Equation, which calculates the amount of power an antenna receives from another antenna under ideal conditions. Other requirements for RF systems are that antennas must be far field in an unobstructed space; broadcast and receive over a narrow bandwidth so single wavelength can be assumed; and have correctly aligned and polarized antennas.

The Friis equation is: