One of our recent audience surveys told us that electric motors and actuators are respondents' primary machine motion source. No real surprise there. But about half of the survey respondents reported that their primary power source was a combination of electric plus hydraulic sources, or a combination of electric and pneumatic sources. And about 10% said that just hydraulic sources were their primary power, and 10% reported that they rely primarily on only pneumatics. So the predicted demise of these power sources might take a while longer than some have foreseen.

"Power for the price" was the primary reason given for using hydraulics (40%), followed by "customer requirements" (23%), and "wide power variation needs" (16%). For by far the most respondents, at 33%, the biggest drawback to using hydraulic power systems was environmental/high maintenance issues.

About 45% of respondents preferring pneumatics used them to power linear actuators, cylinders, etc., and not as a primary power. About 21% used pneumatics for control applications while 27% used it for both control and power applications.

"It's a simpler solution" was the main reason respondents used pneumatics (30%), followed by "compressed air availability" (30%), "customer requirements" (14%), "we understand it best" (13%) and "cost of conversion to electric/electronic not viable (8%)."

Respondents reported the greatest drawbacks to using pneumatics are "high cost of air (32%), high maintenance (24%), lack of system diagnostics (23%), inflexibility (13%) and insufficient vendor support (7%).

Know With the Flow

SensoControl Diagnostic Serviceman Plus, a robust handheld meter that provides portable maintenance and diagnostic data for hydraulics and pneumatics, has automatic sensor recognition that scales the measurement range, eliminating setup routines. It has a 1-ms scan rate and can measure pressure, flow, temperature and rpm. All measurements captured can be stored on a nano USB drive or transferred to a PC for analysis and documentation using SensoWin software provided with the meter.

Parker Hannifin;

763/544-7781

SPCS Version 2 (SPCS-2) high-flow servo pneumatic control valve provides electric-like, closed-loop motion control when used with direct feedback pneumatic actuators. It eliminates the need to change manual switches or adjust rotary potentiometers during system setup. System configuration and setup is completed using a standard USB connection and SPCS-2 software.

Bimba

800/442-4622

Pneumatic Drive

DGC-K compact rodless pneumatic drive for simple drive functions and positioning operations has piston size ranges 18 to 80 mm and stroke lengths 1 to 8,500 mm. At six-bar pressure, the drive delivers 153 to 3,000 N. Position sensing is via proximity sensor. It is a double-acting linear drive with slotted cylinder barrel and optional moment compensator. Unique sealing system includes a polyurethane sealing band that snaps into the profile of the device and a magnetically retained metal cover strip to prevent contamination.

Festo;

800/993-3786

Proportional valve module 750-632 simplifies connection of hydraulic or pneumatic valves with flexible valve-control operation modes. Two single-coil valves or one dual-coil valve can be controlled uni- or bidirectionally. For each channel or coil, the output current is 2 A in one-channel operation and 1.6 A in two-channel operation. It has two current-controlled pulse-width modulation outputs (24 V) with adjustable dither. Discrete dither frequency setting minimizes the motion, which is adjusted to the valve around the rest position, allowing the setpoint to be defined without considering static friction.

Wago;

800/din-rail

MSR Series of five linear actuators include configurations such as cross roller guides, adjustable position, shock absorbers, guide bushings, external cylinder. They have a range of operating pressures from 0.2-0.88 MPa. Housings are made of high-tensile, hard-coated aluminum alloy, hard-anodized and maintenance-free for the first 2 million cycles. Speed range is 0.5-0.7 m/s. Stroke ranges 10-50 mm for smallest unit to 30-25 mm for the largest.

Techno-Omil;

800/819-3366

Modular HF03-LG pneumatic directional control valve manifold system provides high flow with low power consumption. Individual valves are less than 16-mm wide with a flow rate of 0.7 Cv and a power consumption of 0.35 W per solenoid. Valve banks are available from one to 12 stations of single, double and dual 3/2 solenoid valves. Electrical control with a 25-pin or 44-pin D-Sub connector or with centralized or decentralized B-Design bus modules are available in Sercos III, EtherCat, EtherNet/IP, DeviceNet, Profibus-DP, Interbus-S, Modbus TCP, ControlNet, CANopen and AS-i protocols.

Aventics;

+49-511-2136-553

M DM2 series C double valve with an integrated on-board soft-start capability allows gradual introduction of air to the system when the valve is energized. The valve can be adjusted to provide slower or faster buildup of system pressure, depending on the ideal setting for application. Rapid exhaust of downstream air when de-energized removes stored energy and allows safe access. Memory, monitoring and air flow control functions are integrated into two identical valve elements.

Ross Controls;

800/438-7677

Air Repairable

NFPA cylinder, repairable NFPA Interchange, has magnetic pistons, adjustable cushions at both ends, hard chrome-plated stainless piston rods, stainless tie-rods, anodized end caps. Cylinders include both bottom-tapped and end-cap sleeve-nut mounting. NFPA mounting is simplified with detachable NFPA mounts.

Fabco-Air;

352/373-3578

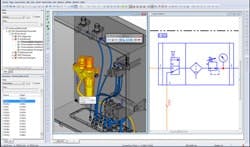

Eplan Fluid is an engineering tool for automated design and documentation of circuits in pneumatic, hydraulic and other fluid power installations complying with current standards such as ISO 1219. The Eplan Platform connects the fluid power engineering with all other engineering disciplines so that various engineering tasks can be executed in parallel, and the entire engineering process is accelerated.

Eplan;

248/871-0469

Nitra solenoid pipeline valves designed for control of air, oil, water and inert gas are two-position, normally-closed, spring-return styles with 24-Vac, 24-Vdc or 120-Vac solenoids, and are fitted with DIN-style wire connectors. Valves have port sizes 1/8 to 1-in. FNPT. Valve models are available in two-way and three-way diaphragm styles; two-way and three-way poppet style and two-way media-separated diaphragm styles are also available.

AutomationDirect;

800/633-0405

Type-90 miniature, precision air-pressure regulator for valves and other automatic control equipment has high resolution adjustment of set pressure, pressure ranges up to 120 psig, two gauge ports and reversible bracket for front or back mounting, and availability in 1/8 NPT, BSP porting and manifold mounting. Flow capacity is 14 scfm at 150 psig supply with 120-psig output. Air consumption is 6 scfh.

ControlAir;

603/886-9400

MapleSim hydraulics library from Modelon allows engineers to incorporate industry-tested hydraulics components while doing modeling, analysis and simulation in MapleSim. The library includes more than 150 components for modeling pumps, motors, cylinders, restrictions, valves, hydraulic lines, lumped volumes and sensors. It enables engineers to produce high-fidelity models by accounting for compressible oil and cavitation effects, resulting in an extremely accurate view of system dynamics.

Maplesoft;

800/267-6583

GV-GTV series of poppet valves have a bubble-tight design with flow rates of 38 scfm at 50 psig; 67 scfm at 100 psig. Two-way and three-way valves are offered in 1/4-in. NPT and 3/8-in. push-quick ports, along with a cartridge-mounted version. A variety of buttons and valve actuators can be used with the GV stem-operated valves. They also are available as toggle valves with panel-mounting capabilities.

Clippard Instrument Laboratory;

513/521-4261

HPP high-pressure, compact, leak-free pneumatic regulators have a piston design to manage supply pressures to 6,000 psi at up to 260 ºC and deliver high output pressures between 3,000 and 1,000 psi. Constructed with 316 stainless steel bodies, the HPP is available with ¼-in. ports in either 2- or 4-port configurations and in multiple output pressure ranges. Standard knobs can be replaced with tamper-proof caps for high temperature or non-adjustment applications.

Rotork Fairchild;

800/334-8422

Latest from Power Supplies

Leaders relevant to this article: