- Smooth driving with linear motion

- Point-to-point acceleration with linear motion

- How to actuate in dirty, wet environments

- New innovations in linear motion

How can I install a linear motion actuator in a dirty, wet machine environment?

Broc Grell is applications engineer at Nexen Group.

Figure 1: High-performance seals are a critical consideration if using linear motion components in harsh or contaminant-rich environments. Plating options are also available to ensure long service life.

(Source: Bosch Rexroth)

In harsh environments, for example, where metal or wood shavings may be present, tested and proven sealing technology for linear motion components is imperative if you wish to achieve the full service life from a bearing system. A good sealing function will keep lubrication preserved within the bearing and keep contamination out of the system (Figure 1). What makes for a good seal? Full interference contact around the perimeter of the component and material that is impervious to the surrounding contaminants.

Clint Hayes is product sales manager, linear motion technology at Bosch Rexroth.

Chris Bullock is applications engineer I at Bishop-Wisecarver Group.

Figure 2: Both rod wipers on rod-style actuators and protective bands on rodless style actuators help with ingress protection from dusty environments.

(Source: Tolomatic)

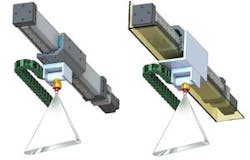

Figure 3: This application depicts a spray head that is directed away from the actuator. The illustration on the left shows a rodless actuator with no shielding that would be susceptible to liquid ingress. The illustration on the right shows the proper way to shield a rodless actuator from splashing water or low-pressure jets in applications where spray heads are directed away from the actuator.

(Source: Tolomatic)

Rodless actuators may be enhanced by the addition of a positive pressure port on the body of the actuator designed to equalize internal and external pressures and help to keep dust away from possible ingress points. In dusty applications, IP54 would be the minimum rating to consider. An actuator with an IP54 rating is protected from dust (5) and splashing water (4), even though splashing water may not be present. In extremely dusty conditions where there are materials being cut, such as in woodworking, or light metal machining and light grinding, the accumulation of dust tends to be considerably heavier. In these applications, a higher rating such as IP65 should be considered, making the device dust-tight (6) and protected from low pressure—4.4 psi—jets of water. Even though there may not be water in the environment, the sealing mechanism for dust exclusion is typically effective for that level of low-pressure water protection. Rod-type actuators that have rod wipers or rod seals also perform well in these conditions; however, rodless actuators typically do not perform well unless some kind of custom-designed protection is applied. Custom-designed protection is best provided by the machinery manufacturer.In applications where water is present, it is important to fully understand the source, direction and volume of the water to which the actuator will be subjected. For example, consider a system in which an actuator is reciprocating a spray head that is directed away from the actuator toward the processed product. Inevitably, some of the water, mist or water vapor will settle back on the actuator. The actuator therefore should have a level of protection against splashing water or against low-pressure jets (Figure 3). Since the sealing mechanism of most rod-type actuators consists of a rod wiper or rod seal, actuators with a rating of IP65 would be satisfactory. Rodless actuators will experience water ingress at some point unless custom-designed shields or guards are applied.

Figure 4: Rodless actuators will not perform well in certain applications without customized protection.

(Source: Tolomatic)

When an actuator is required to be directly in the path of water—for example, the actuator is moving product within the range of sprayed water—additional ingress protection is required. IP66- or IP67-rated devices may be more appropriate in this case. Devices with these higher IP ratings will typically have redundant exclusion mechanisms such as shields, bellows or guards, ensuring long-term functionality. Again, rodless actuators will not perform well in these applications without customized protection (Figure 4).Another common industrial application for actuators is on equipment that requires aggressive cleaning. Equipment used in the preparation of foods and beverages often requires frequent and specific cleaning procedures. In these cases, actuator protection requirements are particularly stringent because food and beverage equipment is often cleaned with aggressive detergent solutions, as well as washed and rinsed with hot 180-°F, high-pressure 1,500-psi water spray or steam. When specifying actuators for applications such as these, there are two important considerations.

- Understand the chemical makeup of the cleaning solutions. For example, the effects of very high or very low pH cleaning solutions on various components need to be fully understood, so the materials used for the sealing mechanism are compatible and do not degrade. This also requires that the metal materials used in the construction of the actuator body be resistant to the particular cleaning solutions.

- Specify sealing materials that are compatible with the cleaning chemicals and resistant to high-pressure and high-temperature water spray. Actuators with a rating of IP69K are best suited for this type of environment. However, it is always wise to perform testing on the solutions used in the process to ensure chemical compatibility. Applications involving chemical solutions need to be treated somewhat differently than applications involving simple water ingress. IP ratings do not imply chemical compatibility. Knowing exactly which chemicals the actuator will be exposed to will help the actuator supplier select materials most likely to offer good service life. Important factors to consider are the chemical makeup of the solution being used, its concentration level, duration of exposure to components to which it is applied and operating temperatures. This information is critical to applying linear actuators in these types of applications to ensure proper functionality and longevity.

Gary Rosengren is director of engineering at Tolomatic.

The second feature that allows SuperTrak to withstand nontraditional linear-motion environments is the mover/pallet design. The movers are held in place by magnetism and are guided with simple rolling elements. This means we can simply shield each mover with a slightly oversized cover to protect the rolling elements and minimize the debris build up on the vertical track face. The magnetic hold is important because there is an inherent air gap between the magnet and the coils in the motor sections, so even a few-millimeter layer of debris and film would not affect the control and dynamics of the system.

Derrick Stacey is solutions engineer at B&R Industrial Automation.

The second common approach is to use actuators that were designed specifically with high levels of ingress-protection (IP) sealing. Traditionally, electric cylinders are able to achieve higher levels of IP, with levels up to IP69K. This prevents all liquid and solid contamination into the actuator. Additionally, these cylinders are often designed with positive external geometry to prevent microbial growth and pooling on the surface. Also, stainless-steel materials prevent contamination. With rodless actuators, effective sealing is often more challenging, given the form factor.

Jeremy Miller is product manager—linear mechanics at Parker Hannifin's Electromechanical & Drives Division.

Focusing on position feedback devices, when installed correctly a dirty and wet machine environment will not affect the signal quality of a linear magnetic encoder in the same way as that of an optical sensor.

Jay Johnson is national product manager at Sick.

ALSO READ: Putting Linear in Motion

Mike Bacidore is the editor in chief for Control Design magazine. He is an award-winning columnist, earning a Gold Regional Award and a Silver National Award from the American Society of Business Publication Editors. Email him at [email protected].

About the Author

Mike Bacidore

Editor in Chief

Mike Bacidore is chief editor of Control Design and has been an integral part of the Endeavor Business Media editorial team since 2007. Previously, he was editorial director at Hughes Communications and a portfolio manager of the human resources and labor law areas at Wolters Kluwer. Bacidore holds a BA from the University of Illinois and an MBA from Lake Forest Graduate School of Management. He is an award-winning columnist, earning multiple regional and national awards from the American Society of Business Publication Editors. He may be reached at [email protected]