A Control Design reader writes: Our plant had standardized on Siemens (Moore) 353 and the Procidia i|pac (353R) process automation controllers. The controllers have been retired and are no longer available for purchase, so I need something to replace them.

We were using them for boiler control, continuous process and batching applications in our plant. The controller was basically a mini DCS with a faceplate that could be used for local configuration and operation. Multiple controllers are connected on Ethernet with embedded HMI platforms, such as Procidia i|station, spread throughout the plant. It has left us with a huge hole moving forward.

While the existing controllers use Boolean function blocks or ladder logic programming, I do not enjoy writing code. However, I am very good at configuring controllers with the standard languages. Any suggestions on a controller and HMI to ease our upgrade project from both a hardware and a software standpoint? Please help.

Answers

Stay in the family

I would suggest they look at the Siemens S7-1200 or 1500 controllers using TIA Portal for programming. It has the structured languages needed to replace the function blocks in 353s and Procidia. There are others, but if they are familiar with the Siemens products this in the "family."

I would also suggest they look at doing a FEED study to review the options and logic and how best to approach the migration. Most likely the batch option is simple recipe management or sequencing which can easily be handled in the PLCs mentioned. If it is more complex batch, then they may need to consider a batch server which would be closer to the PCS 7 system. My guess is the S7-1200 or 1500 will handle what they have.

Jeff Morton / sales manager, process control integration group / Cross / Control System Integrators Association (CSIA) member

From the source’s mouth

In response to your query for upgrading your Siemens (Moore) 353 and the Procidia i|pac (353R) controllers, I have reached out to Siemens to see what they recommend. They stated that they performed a comparison on the 353 controllers when they went obsolete and found that all of their functionality could be performed by the newer S7-1200 controllers they now offer. This will require quite a few configuration changes, but they also offer services to assist with that, as do we if you are looking for an integrator. It is possible that you would be able to replace multiple 353 controllers with a single S7-1200 PLC as the hardware is changing from a single-loop controller to a multi-loop controller. The same is possible with the 353R, but that depends on the I/O configuration there; they may require a one-to-one replacement for each one.

Jerry Flynn / principal engineer / Concept Systems

Don’t fear the programming

I am unsure what is meant by “standard languages.” It seems this reader does “not enjoy writing code,” I suppose in reference to the Siemens 353 using function blocks for programming, and perhaps also desiring to not use ladder logic, as is common in most programmable logic controllers (PLCs). If, by “standard languages,” this reader means something like C or C#, then the reader may be a good candidate for the IEC 61131 programming environment.

IEC 61131, or more properly, IEC-61131-3, is a programming environment which, by definition, has five programming languages:

- ladder diagram (LD), graphical

- function block diagram (FBD)

- structured text (ST)

- instruction list (IL)

- sequential function chart (SFC).

Obviously, IEC 61131 contains two of the languages that may be undesirable to the reader, LD and FBD. But it also contains ST and IL. ST is more like programming in C. It is a very familiar format to someone who is comfortable programming in a Microsoft .NET environment. To me, IL always seemed something like programming in the Microsoft Macro Assembler (MASM), with instructions, such as LD for “load the accumulator” or JMP for “jump to another location in the program.” These may be much more comfortable programming languages for this reader.

The two most popular IEC 61131 environments are produced by German companies, CodeSys made by 3S-Smart Software Solutions and CodeSys made by KW-Software, which was acquired by Phoenix Contact some years ago. Advantech offers both of these software solutions in some of its hardware solutions. It is worth mentioning that CodeSys added a sixth programming language to its IEC 61131 environment called continuous function chart (CFC).

There is another company that produces an IEC 61131 solution named ISaGraf made by a company name ICS Triplex, which was acquired by Rockwell Automation some years ago. Although ISaGraf may not be as well known, it is notable because it incorporates both IEC 61131 and IEC 61499 programming environments. IEC 61499 is more like a function block language, but it graphically incorporates the hardware used with the programming language to facilitate distributed control methods. Centralized control methods are more commonly found in North America, where distributed control methods are more commonly found in Europe. A blended solution may become the most common of all, but IEC 61499 is probably not a good solution for this reader’s needs. ISaGRAF is found on a number of Rockwell Automation’s Micro PLC products.

The Siemens 353 is basically a loop controller. There are many brands of loop controllers available from many manufacturers. When this reader says he or she does “not enjoy writing code,” the reader may be looking for a hardware solution with fill-in-the-blank type simple programming or configuration. This type of loop controller frequently has very little flexibility. The Siemens 353 had significant programming capability and flexibility, which means it was probably custom-configured to accommodate the reader’s application. It is very likely that the reader will have to either reference engineering documents, which specify how these control loops were programmed and what the operating parameters are, or the application will have to be reverse-engineered to determine every meaningful aspect of the application. The chances are that something more than simple preconfigured loop controllers will be needed, and the reader will have to do some programming.

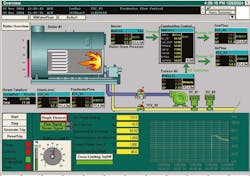

Finally, Advantech offers a number of products capable of doing loop control. We offer the ADAM-3600 Series, which comes with a free lite version of KW with free development software. We also offer the APAX-5580 Series which comes with CodeSys (Figure 1). The APAX-5580 is a powerful PC-based system with options of a Celeron processor or core i3 or i7 processors. It has a modular native I/O system with the typical analog and digital modules and the processing unit has an HDMI port that allows connection of a display such as Advantech’s FPM flat panel touchscreen monitor. CodeSys does support an optional HMI software module called Target Visu, which would provide an all-in-one solution to replace the Siemens 353 loop controller.

Figure 1: Something more than simple preconfigured loop controllers will be needed, and the reader will have to do some programming.

(Source: Advantech)

Chuck Harrell / IIoT product marketing / Advantech

Modern problems

Your problem is a common one. According to ARC Advisory Group, there are $65 billion in installed process automation systems nearing or past end of life. Many users like you have successfully maximized automation investments by keeping systems running long past the point of obsolescence.

Why do users resist modernizing? You list a couple of common reasons. You are still able to run your plant, skilled in configuring existing equipment and not excited about learning a new system. Other common barriers include financial justification and downtime concerns.

However, the benefits of automation modernization greatly outweigh the challenges. You can have a supported system with available parts from the manufacturer and fewer failures. A modernization done right often results in improved product quality, increased production, lower support costs and fewer process upsets. As you’ve probably noticed, not many people are proficient in old 353 controllers. The ones who remain are close to or already past retirement age. Being on a modern platform helps make sure you can find resources to help with your control system.

So, what modern automation system makes the most sense for your application? Making the selection can be a daunting task given rapidly changing technology and numerous options available. Rockwell Automation helps guide engineers through the selection and justification process.

There are a few options, but based on the information in your inquiry, the PlantPAx distributed control system (DCS) from Rockwell Automation might be your best choice. Many users enjoy the scalability, ease of configuration and numerous support options. The PlantPAx system also brings multiple devices into one system to help minimize maintenance.

An automation system modernization is a once-in-a-generation chance to make a substantial improvement in your facility’s operation. The automation system is the brain of your plant, so an upgrade can make a significant impact.

Lee Swindler / program manager, Maverick Technologies / Rockwell Automation

5 steps to hybrid

Boiler control, continuous process and batching are three very different applications, so you will need a system that has a variety of control functionality. Since you are doing boiler controls, you may also require something that can handle burner management controls for flame detection and fuel shutoff to comply with NFPA rules. Your application sounds like a standard network in which you have islands of automation. A product like EcoStruxure Hybrid DCS has the capabilities to meet each of your requirements. Let me explain how.

1. Our system can easily incorporate ladder-logic code and discrete function blocks into a full function block strategy. Benefit: Simplified logic creation through the pre-created control blocks that will fit the needs for these applications such as analog, digital, sequence, PID and valve blocks. These control blocks are available in a standard documented library for quick access. This also makes troubleshooting very easy because of the formatted nature of the blocks, meaning they will be consistent today and next year. When you couple this with our Run Time Navigation Services, your troubleshooting capabilities are enhanced even further.

2. Local HMIs and central HMIs (Figure 2). This is a common problem that is solved by the EcoStruxure Hybrid DCS. The DCS is maintained in a central fashion but the local HMIs are simply structured as nodes. Benefit: You create and manage the local HMI screens on our Magelis HMI system and deploy them from the central location. This ensures that local HMI panels are always up to date and consistent since there is no separate tool to build graphics at each local panel.

Figure 2: Create and manage the local HMI screens and deploy them from the central location.

(Source: Schneider Electric)

3. Through our batch software integration, we can do full batch management solutions, less complex recipe applications or even simpler sequence logic all with the same controllers, I/O and software. Benefit: You will require only one platform for all the applications (Figure 3).

Figure 3: Through integration, less complex recipe applications or even simpler sequence logic can be done with the same controllers, I/O and software.

(Source: Schneider Electric)

4. A couple of things that you didn’t mention that I’d like to address include lifecycle management. First, you noted that your Moore devices are obsolete. We maintain a Continuously Current technology philosophy, meaning we will always develop tools that allow users to maintain the existing infrastructure and logic for their control system. They can migrate to newer versions while still maintaining the code they have standardized on and the wiring they have installed, mitigating a very high-risk and expensive effort if needed to be changed with the new system. Second, we have done many Moore migrations and because our system is so compact, we can usually fit the controllers and I/O into the same cabinet space, saving money and risk. Third, we have done projects with Moore devices where we have migrated the exact HMI graphics into the HMI of the EcoStruxure Hybrid Control System. This will make any training much simpler. Fourth, the execution strategy for cutover can be managed in a staged fashion. Fifth, there are many asset management functions that are embedded that will help you balance the uptime of your assets with the maintenance of your capital equipment.

5. Finally, as an organization Schneider Electric’s Process Automation division has completed hundreds of boiler projects and burner management projects (Figure 4). We can support any design requirements or recommendations to improve the process or the architecture. We also work with qualified system-integrator partners who can develop these strategies for you, as well.

Figure 4: Boiler projects and burner management projects can be supported and improved.

(Source: Schneider Electric)

Mark Grant / business development manager / Schneider Electric

Go Simatic

Siemens has a number of automation options that would be a suitable replacement for the Siemens (Moore) 353, Procidia i|pac (353R) process automation controllers. For example, our new AS 410E CPU was designed specifically for the small process applications that require continuous, batch and even safety functionality and leverages the exact same PID algorithm used by the 353 controller. The 410E CPU is seamlessly integrated in our proven process control system, Simatic PCS 7. Its robust, powerful hardware makes it flexible to use, even under demanding conditions. It comes standard with dual Profinet interfaces to provide fault-tolerant and reliable communications, all the way to the field level where you could leverage our decentralized Simatic ET 200SP HA I/O modules perfectly tailored to the requirements of the process industry today and for the digital plants of tomorrow.

Charlie Fialkowski / process safety manager / Siemens

Try something new

There are many new easy-to-use controllers on the market today that can fill the void and replace the retired controllers. New on the market is the Opto 22 GRV-EPIC-PR1 on-the-rack controller for the groov edge-programmable industrial controller (EPIC) system.

The controller is an embedded Linux real-time controller with gateway functions.

The modern design of the groov EPIC processor offers a condensed and sturdy unit that features a resistive-touch, high-resolution LCD display. The LCD display lifts to provide easy access to the power button, power supply connectors, network interfaces, ports and status LEDs.

Dual, independent Gigabit Ethernet network interfaces enable the processor to maintain separate connections to your back-office network and your controls network.

Dual USB ports extend the capabilities of the processor, so it can handle serial communications, communicate with touchscreen monitors or connect to your network with approved Wi-Fi adapters.

HDMI port displays configuration and groov View HMI on an external large screen, which is also useful for OEM applications where the EPIC system is built into a machine.

The processor can operate through a wide range of operating temperatures (-20 to 70 °C), and, with its sturdy design, it can be used in a large variety of applications and operating environments. It runs on an industrial, quad-core ARM processor with a real-time, open source Linux operating system.

Software tools include:

- groov Manage for browser-based management of your groov EPIC system

- groov View for building and viewing custom operator interfaces for local, mobile, and browser-based devices PAC Project Basic Software Suite for developing control programs and a traditional HMI (plus available Shell access for custom applications you write)

- Node-RED for creating simple logic flows using pre-built nodes

- Ignition Edge from Inductive Automation for connecting to Rockwell Automation, Siemens and Modbus/TCP devices via OPC UA and for efficient IIoT communications using MQTT with Sparkplug payload.

You can run complex control programs on the groov EPIC processor developed with PAC control or your own custom applications.

The groov Manage app is your central command to your groov EPIC system, helping you configure, troubleshoot and commission your controller, I/O modules and network interfaces. The consistency in interface design between the groov Manage app running on the groov EPIC processor and the groov Manage app running on your computer, smartphone or tablet ensures a seamless experience between devices. You don’t have to remember to do something different for each device to achieve the same result.

Groov View offers easy browser-based development of a custom HMI with trending, events, and user notification. Communications are secured with user authentication and encryption. And, because the HMI is independent of operating system, what you build can be viewed on any authorized device.

The GRV-EPIC-PR1 is part of the groov EPIC system, which provides a complete control and communications system at the network’s edge, including:

- I/O: Connect to field devices and translate their electrical signals into the ones and zeros that computer systems understand.

- Control: Automate equipment and systems at the network’s edge. Use the included flowchart-based control development software, or build your own custom program.

- Data handling: Acquire, move and share data from industrial systems, legacy equipment, business and IT systems and the cloud.

- Visualization: Securely monitor, control and use data as you need it—locally, on premises or from anywhere using an authorized mobile device, computer or anything with a Web browser.

The groov EPIC system builds on decades of field-proven design and modern open standards to give you reliable industrial automation plus a full Internet of Things (IoT) communication structure, built-in.

The system includes processor, software, I/O modules, chassis and power supply.

The chassis holds the power supply, processor and other I/O modules you need for your application. Power supplies are available for ac power, dc conversion and pass-through connections from a power supply you already own.

Danny Weiss / senior product manager / Newark element14

Get your groov on

The new groov EPIC controller from Opto 22 has a built-in HMI on the front with a high-resolution touchscreen. You can configure and test the unit right from the front of the unit. You can even bring up electrical wiring diagrams of all the I/O.

Figure 5: There are many new easy-to-use controllers on the market today that can fill the void and replace the retired controllers.

(Source: Opto 22)

To configure the HMI, EPIC includes groov View, a codeless, drag-and-drop HMI builder to create screens that your authorized users can see and interact with, both on the local touchscreen or via a Web browser running on any computer, mobile device or smart TV. Groov View also provides trends, events and notifications.

Second, you can program the EPIC controller in many ways. You can use the native PAC Control flowchart programming environment, which is included for free and used by process control users all over the world. PAC Control is very intuitive, so it’s easy and quick to get up and running. Another programming option is SSH, shell access to the Linux OS, which means you can program in Python, C# or C++, for example. And you can use the built-in Node-RED to connect to databases or other cloud services either on premises or off, thus enabling your batching applications and boilers to become IIoT-ready.

Third, EPIC controllers come with four, eight or 16 modules of high-density guaranteed-for-life I/O, in both isolated and non-isolated configurations.

Ben Orchard / senior application engineer / Opto 22