A Control Design reader writes: With so many new devices including intelligence, do we still need a controller, whether it’s a physical component or software-based? Doesn’t edge or cloud computing replace the need for a PLC/PAC? What about PC-based control? How do we coordinate these smart devices into one system?

Also read: New technology pushes machine smarts to the edge

Variable and unpredictable lag in feedback can be devastating

For real-time systems, control and feedback need to be driven to the lowest level that is practical. Reporting what happened, especially if it is routine bean-counter information, can be made after the fact and can often be delayed by seconds to hours without any loss of value. Measurements made that affect the real-time functioning of a system—where to apply a label to a package that is transiting, sensing force in a system to limit the power into an actuator and any safety-related functions—all need to always be made in a time consistent with the system.

Control systems regulating force, position, speed or temperature typically need the feedback no later than about 5% to 10% of the actuator response time to keep from significantly affecting the operation of a control loop. A force-sensing arm may need to begin deceleration based on when the threshold force is reached. A delay of milliseconds or hundreds of milliseconds could crush the package being handled. Having your screen pause updating when browsing might be annoying. Delaying the braking of an autonomous vehicle could be deadly.

Delayed feedback can make an otherwise stable system go into oscillations. Think of driving while watching a 10-second delay on a camera looking outside the car. Reacting in time for the dog that darts out or the deer jumping in your way just is not going to happen in time. Would you consider investing based on last year’s Wall Street Journal? Just so, lag, especially variable and unpredictable lag, in feedback in a system can be devastating. The function of the PLC/PAC can be driven downward, that is incorporated closer to the action, but great care should be taken when moving it further away, especially when the communications channels are shared.

An extreme case is looking at NASA’s control of craft on Mars. Even with a predictable delay, the delay time would force a very slow approach; for a successful mission, control needed to be kept within the remote vehicle, with only panic conditions stopping the vehicle until NASA Jet Propulsion Laboratory (JPL) can respond, with approximately 30 minutes of round-trip time delay, according to the relative position of the planets. Having a production line go down because someone sharing your Internet connection decides to download the latest Linux or Windows update is not a good option. And the opportunity for an active denial of service disrupting or damaging a system cannot be safely ignored.

Donald Labriola P.E.

president / QuickSilver Controls

The overlap of edge computing and traditional PLCs

It depends on what we think about PLCs and other controller options. If we think of a PLC as tied to ladder logic and programmed by electricians, then the PLC is relevant but plays a limited role. However, if we define a PLC as a rugged computer that is capable of interacting with sensors and actuators in near real-time and also acts in conjunction with higher-level systems and perhaps working in an informed manner based on artificial intelligence (AI)/machine learning (ML), then this edge-located functionality is very important. In a broad sense, edge computing and traditional PLCs are overlapping concepts.

It's important to break down control into two levels: micro-control (μcontrol) and macro-control:

- μcontrol: A micro-controller is optimized to operate at the industrial edge for interacting with field sensors and devices, providing direct control. For example, given a setpoint, a μcontroller can change the actuator—valve opening—controlling the process variable to match the setpoint as efficiently as possible. A μcontroller is mission-critical, requires high availability and must support near-real-time reaction.

- Macro-control: A macro-control system is for performing analysis and finding optimal setpoints. This can be done on a PC and even the cloud and on lower frequency—5 minutes or longer, depending on applications. In many applications, such as greenhouse control, the optimal control algorithm can be too sophisticated to be practically programmed on a traditional PLC.

In traditional industrial automation terminology, some of these functions are encompassed under supervisory control and data acquisition (SCADA). However, most SCADA systems today only provide visualization and an interface for operators to change the setpoints. So, the operators are the effective macro-controllers. In most automation setups, even at advanced ones, operators must look at multiple screens and make repeated/mundane decisions. “How to grow disruptive automation with AIoT” explains this distinction.

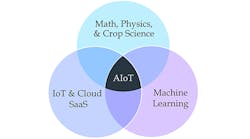

Given the decreasing costs of both traditional and modern μcontrollers, such as RaspberryPi-based PLCs, many such PLCs can be distributed throughout the plant for ease of wiring and all connected to a central PC. Local μcontrollers combined with higher-level systems combine to deliver artificial intelligence of things (AIoT) functionality, which exists at the intersection of traditional and new sciences and technologies (Figure 1).

Austin Miller

virtual intelligent automation consultant / Koidra

Expandable infrastructure for adaptation

The overall architecture of a control system is dependent on the size and scope that you are trying to achieve. It is best to have a dedicated PLC to control an individual piece of equipment or machine. In this way, the majority of your equipment could remain operational if one PLC goes down. In a larger, more complex system, it is best to have multiple PLCs operate under a supervisory master PLC or PAC.

PC-based control is historically used for extremely fast control/response, but the modern PLCs are well-equipped to compete in speed with many PCs, provided the system is properly engineered.

Regardless of the size or scope of your system, it is critical to install expandable infrastructure early on. This will allow you to adapt your processes as technology advances.

James Potisk

application engineer / Automation24

Integrating multiple edge devices

While smart devices and edge control reduce the dependency on a central controller, they do not eliminate the need for it. Edge devices can provide standalone control of a specific function, but integrating multiple edge devices together for coordinated sequences, redundancy or safety shutdowns requires a device that can communicate to multiple edge devices at once. This is where the controller still provides a valuable function. I believe this is what the last part of the question was leading toward—the answer is still the central controller.

Alan Polk, P.E.

technical innovation leader / Hargrove Controls + Automation, certified member of CSIA

Edge computing bridge between factory data and the cloud

Edge computing encompasses the whole set of infrastructure, tools and processes that support managing data-handling activities using individual sources of data, such as smart edge devices at the network's edge rather than on centralized infrastructure. Edge controllers can provide advantages in many applications where traditional industrial controllers have been used. For commercial and industrial computing products, software-and-hardware-development progress proceeds in tandem, with the lead alternating. Sometimes the software complexity and features increase in a way that bumps into processing limitations; then there are times when hardware advances unleash newfound capacity for more sophisticated software.

The trend toward event-driven architectures in information technology (IT)/operational technology (OT) provides a unique opportunity to connect factory-floor data with cloud-based smart-management solutions. Edge computing serves as a bridge between the two, linking changes on the manufacturing floor to enterprise resource planning (ERP) and management systems meant to automate business operations and provide insights quickly and efficiently.

In many instances, integrating Internet-of-Things (IoT) data processing and other tasks directly into a module intended for industrial automation, such as a programmable automation controller (PAC), may make more sense. PACs, which do have higher-performance processors, could run a broader range of software than PLCs. In contrast to ladder logic, PACs now provide visual and textual programming languages, enabling more sophisticated manipulation and analysis of real-time data from local and remote sensors.

Some PACs have an architecture similar to that of a standard PLC. It may also host smart control modules, which allow for the simple installation and operation of motors and other similar equipment for speed, stop and start instructions. Another type of PAC has emerged in recent years, combining the capacity to handle local I/O with network connectivity and the software programmability of intelligent gateways.

These PACs are built on hardware platforms like Arduino, Raspberry Pi and Linux-powered industrial computers. As a result, they provide access to a variety of programming tools, such as Node-RED and Python.

Modern network connectivity of PAC platform capabilities enables integration between the safety-critical environment of the PLC and the thin edge, as well as the analytical functions typically performed in the thick edge and the cloud.

Industrial edge controllers offer software-defined controls with enhanced optimization capabilities, all while meeting the rigorous reliability, safety and security requirements of industrial applications.

Edge controllers are the logical choice for industrial automation and IIoT due to their combination of control tasks and edge processing. Edge gateways, edge devices and the new edge controllers that merge PLC/PAC and edge processing into a single system are the major forms of industrial edge technology within machine automation.

Edge controllers provide a generational leap forward for PLC- and PAC-based industrial control systems by providing a safe, secure connection between real-time deterministic control and non-deterministic applications that analyze and optimize business processes utilizing external data.

Basic PLCs are often “bare metal” designs or utilize a very limited and proprietary operating system since they are specialized control devices with a defined functional scope. Through the usage of a real-time operating system (RTOS), PACs obtained more sophisticated communication and functional services while maintaining a deterministic runtime.

PLCs were formerly isolated or communicated over slow and inefficient serial links. PACs included better industrial protocol implementation and Ethernet to increase connectivity and interoperability. Edge controllers provide these benefits while still being able to function in an increasingly IT-connected environment.

PLCs mainly employed proprietary ladder logic and rudimentary tools for application development. PACs may provide support for conventional IEC-61131-3 programming languages, custom user code blocks and some basic capabilities for code reuse and object-oriented design by incorporating ideas from the greater software industry.

A well-designed edge controller maintains deterministic runtime while also providing a computing environment for doing analytics, data aggregation and other sophisticated functions.

When users only require a PLC/PAC feature set, an edge controller can be specified to serve that role. Those who are interested and may be more technically savvy, however, should look for edge controllers that have a native toolbox of IT-friendly capabilities, such as Linux OS, a Python interpreter, secure sockets, an embedded database and OPC Foundation/OPC UA compatibility.

It is simpler to securely coordinate the deterministic and general-purpose OS on a single hardware platform than to install separate systems. The general-purpose operating system has access to a broader range of information sources, as well as high-fidelity data from the deterministic system and IIoT devices.

It also has the ability to do local analytics and sophisticated algorithm execution. The results may be used to advise the deterministic system on how to run optimally. Furthermore, the general-purpose operating system is suitable for converting raw data into pre-processed information that can be safely shared with higher level systems.

As technology advances, the gap between the two appears to be diminishing. However, there is a difference between utility and performance. Owing to the ease of programming offered by PAC modules, it is easy to attach or detach components from PACs. PLCs, on the other hand, are wire-based systems, and the addition of devices necessitates extra cabling since small footprints and compact terminations are difficult to wire using traditional methods.

Internet-of-Things devices are becoming commonplace, and many are looking at incorporating IIoT devices into automation systems. Digital transformation requires connecting with many data sources, collecting and storing the data and visualizing and analyzing it, enabling optimized operations.

The journey to realize value in these trends calls for something new—an edge controller that is more than a PLC or a PAC.

Edge controllers are making it possible for implementation of robust automation systems to continue as they always have and seamlessly add the latest communication and application development options.

Edge controllers can upgrade existing systems, create new designs, improve productivity, address skill gaps and enhance security.

PCs and servers used in conjunction with industrial controllers already benefit from this improved computing performance coming from the fast-paced commercial world.

PLCs and PACs are good technologies developed during different eras. Edge controllers can update or replace PLCs and PACs to address current challenges. Edge controllers can offer advantages by implementing carefully designed operating systems for addressing OT and IT needs for control, communications and application development.

PLCs used to be isolated, or they communicated with slow and cumbersome serial links. PACs included better industrial protocol implementation and Ethernet for improved connectivity and interoperability. Edge controllers deliver these advantages, but users must take things to a whole new level to perform in an increasingly IT-connected environment.

When users only need a PLC/PAC feature set, they can still specify an edge controller to fill that role. Standard IEC-61131-compliant programming methods, or even commercial languages such as C, can be used. These users never need to access the general-purpose OS features if they choose not to.

Daniel Weiss

senior product manager / Newark

Figure 2: The increase in intelligent devices will lead to opportunities in the industry, but controllers will always be needed to oversee the process.

The next evolution of controllers

Controllers will always be needed, sometimes physical components, sometimes software-based and sometimes a combination of both, although, the trend is for more software-based controllers.

However, the increase in intelligent devices will impact controllers. As devices become more intelligent their ability to complete tasks increases. As such, some tasks completed by the controller might move from the controller to the device. But this increased responsibility doesn’t mean that the devices are in control. The controller will always be the central point of management for the whole operation (Figure 2).

The increase in intelligent devices is also contributing to the next evolution of controllers, AI-based controllers. AI-based controllers can learn from the received data to optimize the relevant industrial applications and make the factory or similar more efficient.

AI-based controllers require a lot of processing power, which is another reason to use software-based controllers, as it’s easy to scale software-based controllers regardless of whether the software is in the cloud or stored locally.

Even with edge or cloud computing, you will need some sort of controller. This controller could be an industrial PC (IPC) that’s deployed in the edge or cloud, rather than the more conventional PLC or PAC.

If the controller is in the cloud, intelligent devices will play a more important role in ensuring the reliability and performance of the entire system, as they can complete more complex tasks. For example, intelligent devices could pre-process the data, sending only the relevant data to the controller and thereby minimizing the amount of data transmitted. This could be a big benefit in certain applications, such as where cellular technology is used to transmit the data.

PLCs and PACs have several advantages compared to PC-based control or IPCs. PLCs and PACs are built to work in the harsh conditions often found in industrial environments. PLCs and PACs are also dedicated pieces of hardware solely focused on the relevant industrial application. This sole focus enables the PLC or PAC to allocate all resources such as CPU and memory to the relevant industrial application. This helps to achieve the high-speed performance required in factories and minimize the risk of downtime.

Patch management is also easier in PLCs or PACs, whereas on an IPC you usually need to also patch the OS before you can patch the industrial application, which increases the risk of downtime.

With smarter devices, more sophisticated configuration programming tools are needed for the control system being used regardless of whether it’s a PLC, PAC or PC-based application.

Over the long term, it’s likely that device-to-device communication will happen between some smart devices, which will offload the relevant controller. But, even with an increase in smart devices, we will still need a controller to oversee and coordinate the process.

Joakim Wiberg

head of technology / BU Anybus

Cost and performance dictate edge-device scalability

This answer will depend on a number of factors, including the application requirements, target cost and support/maintenance of the machine. While intelligent devices will continue to grow in functionality and performance, PLCs and PACs provide flexible, scalable solutions for manufacturing applications. The target cost will depend on the selected components and their integration time. From a support and maintenance perspective, PLCs and PACs are typically programmed in ladder logic, which has long been the industry standard.

With cloud computing, this provides a centralized, high-powered computing environment to manage data and run applications, but the resource allocations, bandwidth and the potential for high-latency communication between the cloud and a production system, can be a limitation. Cloud computing can have additional costs due to the memory, bandwidth and maintenance requirements.

For the decentralized approach, edge devices can be installed closer to the application. With edge devices and their computing environment, they can provide low latency and improved performance to analyze the data and apply the next steps in the automation process. With edge devices, it’s important to identify limitations in scalability and to weigh the costs versus performance requirements.

As cloud computing and edge devices continue to expand, the programmable controllers should be open to integrating these components to take advantage of the functional benefits.

PC-based controls can offer a secure, open operating system, with both real-time and functional extensions for third-party providers to incorporate their intelligent devices—cloud service, edge devices—directly into the machine’s control system. From an integration point of view, while the standard PLC programming languages, such as ladder logic and structured text, are supported, this open control system should provide additional programming options, such as Python and low-code options, for ease of use.

Dave Boeldt

product manager / Bosch Rexroth

3-layer optimal architecture for smart and non-smart devices

It seems there is a general misunderstanding about the intention/purpose for any device to be intelligent. Intelligence is good, but not always the top priority for all devices, especially for the devices in factories. For example, the top priority for controllers in a factory is robustness/reliability, instead of being intelligent.

With such understanding, one vulnerability/drawback with cloud-computing control is obvious. Normally, servers running cloud computing are far away from devices, sensors and actuators. In such cases, any network outage will be disastrous for factories relying on cloud-computing control.

While edge computing, usually within factories, can help avoid the disaster during network outages, it does not eliminate the necessity of using a controller. Quite often, factory operations require a real-time/deterministic control on devices, which is generally not the focus of edge computing. Rather, edge computing focuses on data analysis and communications with cloud.

With these considerations, the following three-layer architecture seems to be an optimal structure to coordinate all smart devices and non-smart devices of one system:

- one layer in remote—top layer: cloud-computing

- two layers in local—middle layer: edge-computing; bottom layer: controller (PLC/PAC).

What about PC-based control in the context of this architecture? PC-based control is actually almost the same meaning as soft-based control. Similar to the evolution from PLC to PAC that took place around the beginning of 21st century, there is currently a trend to evolve from PLC/PAC to PC-based control. Both evolutions are made possible because of the emergence and popularity of multi-core CPUs, so that some cores can be spared for real-time/deterministic control, while other cores can perform regular PC tasks or even edge computing tasks. Thus, the following two-layer architecture could also be possible or become popular in future:

- one layer in remote—remote layer: cloud-computing

- one layer in local—local layer: PC performing all functions of edge-computing plus controller.

Jerry Lian

product manager / Advantech

Decentralized/central control vs. real-time capable control

Generally speaking, the intelligence that smart devices provide is in the form of more plentiful, complex and consumable data compared to traditional industrial devices. This is great for data-acquisition or remote-monitoring applications. They may also support some control functions and the ability to communicate with other devices. However, they do not typically provide enough decision-making logic to coordinate complex process control in a completely decentralized way. And many smart devices do not necessarily support real-time responsiveness.

Pure cloud-based options, whether a virtual SCADA or soft controller or a cloud IoT platform, can provide centralized coordination, but, again, you may be limited by the level of responsiveness the system can deliver. Certainly, for critical control applications, a hybrid architecture that includes local failover will be required.

Figure 3: Edge computing options can replace traditional controllers as part of a hybrid edge-cloud solution.

On the other hand, edge-computing options, like edge controller and edge I/O systems, can indeed replace traditional controllers, either as part of a hybrid edge-cloud solution or purely for local control (Figure 3).

They provide data processing, security and networking capabilities that a PLC/PAC will not, and they provide a better guarantee of responsiveness than a pure cloud system does. Their capabilities overlap with industrial PCs, but generally the total cost of ownership will be more attractive.

So, it really depends on what you want to do. For simple applications with a generous tolerance for latency, it may be possible to use a decentralized approach or to move central control completely to the cloud. Otherwise, you will want to have a real-time capable controller of some kind nearby.

Garrick Reichert

senior applications engineer / Opto 22

Synchronization demands increase with performance requirements

Even as individual devices become smarter and more connected with IIoT, their abilities to be effective relies heavily on an engineer knowing how to properly integrate them together in a system. Smart devices working without knowledge of the surrounding machine can perform sub tasks on a machine, but overall throughput and efficiency will be higher when a process is coordinated.

This coordination needs shift to synchronization needs as performance requirements increase, and that’s best managed by a centralized PLC/PAC.

Edge and cloud computing are increasingly popular as data-science and AI needs grow on the plant floor. They aggregate massive amounts of data to build models and monitor process activity, but cloud computing is too far removed from the machine for reliable high-performance control.

Edge and cloud computing are effective for processing larger amounts of data over time, whereas PLC control is far more effective for processing data to make decisions in real time.

PC-based control is a great solution.

An IPC with the CPU cores split can run a real-time operating system (RTOS) on half of the cores and Windows on the other half of the cores. The soft version of the controller can run on the RTOS, and it can communicate to the Windows side via a hypervisor.

This arrangement provides the best of both worlds by allowing the dedicated controller on RTOS to focus on machine control, while still providing access to the CPU via standard PC programs in Windows.

Coordinating these devices comes down to identifying what needs to be controlled on the machine and whether the PLC or PC/cloud is best-suited for each specific task. Device control for sensors, servos or actuators are best supported by the PLC, whereas data analytics and supervisory programs are typically best supported by a PC or the cloud.

Paul Anderson

technical manager / Omron Automation Americas

Edge computing keeps data transfer and storage cost low

There are no simple answers to these questions, and it depends on the use case/application. The real-time needs and tolerance of the application may dictate the use of a PLC or a local controller versus the cloud.

Factors such as the application environment that require mounting the devices in a special enclosure, vibration and power supply considerations may exclude the use of a PC-based device. A specialized PLC will be easy to maintain compared to keeping the operating system (OS) of the PC updated along with the application. Using a single device certainly lowers the initial installation cost, as well as maintenance cost, but it also makes for a single point of failure.

Edge computing makes it easy to do some data processing at the local device and speeds up local control. It also helps in reducing the amount of data to push to the cloud—keeping the data transfer and storage cost low. Cloud computing can help in analyzing the data later and works if there is no real-time control required from the cloud. There is an inherent communication delay between the local device and the cloud server, which may not work for a motor-control application, but it may be OK if you are just controlling the temperature of an office space. But this may not be an optimal setup for temperature control in a pharmaceutical application. A communication loss with the cloud application can also disrupt the local process.

An edge device can keep the local process running smoothly, as well as keep storing the data locally until the communication link with the cloud is restored.

Harpartap Parmar

senior product manager / Contemporary Controls

From automation to autonomy

If we use the human body as an analogy for automation, a controller functions like a brain. This also explains why even smart devices including robots still require controllers to manage their actions. Whether it’s from a specific hardware-based controller or a general-purpose computer, the key component of the controller is still software, making it crucial.

Think of smartphones, which combine hardware with applications, as an example; it is the software/application that drives/delivers the true value.

Many industries are gradually moving from automation to autonomy, and there are two key factors to achieve autonomy: data collection and intelligence. Autonomy requires the transmission of data to the right place at the right time through precise intelligent algorithms and data collection.

PLC/PACs have limited computing power due to price and functionality restrictions, while PC-based controllers have higher computing power and can easily construct data acquisition with added support for edge-computing software upgrades.

Virtualization and software are important factors to consider. Fine-tuning functions and combining application-defined domain knowledge and automation through software are key to integrating diverse processes and scenarios. This is the advantage of a PC-based controller.

Cory Kress

senior solutions architect / Adlink Technology

Controllers for all

Any system above a very small machine is going to need a controller. Something has to read the inputs, determine conditions and then initiate the response in terms of activating the output devices and do so in real time. The real question here is: What is the best way to do control in a modern automation system?

I am not sure that cloud computing, at least at current technology levels, is quite ready to be the standalone, single controller. Network security has improved exponentially, as has network reliability. But for a cloud computer to act as the controller, the OT staff needs to be confident that a key system is connected to the outside full-time and hugely confident that the connection won’t fail or experience extreme latency.

I see much more promise in edge computing because there is less dependency on external networks and remote sources. Edge computers could easily coordinate smart devices and function as both traffic cop and data collector. Processor power is there, and there are a number of real-time software programs that could be used to control processes.

Interestingly enough, there are edge computers that also can function as PLCs, with built-in ladder-logic and structured-text programming capabilities, so that there is no need to make a PLC vs. edge decision.

Many modern PLCs are essentially PCs with a real-time kernel, so I’m not sure that there is as much distinction between PC-based control and PLCs/PACs. It is more of an artificial divide. Can a PC with real-time software do anything a PLC can do? Sure. But PLCs, at least for smaller applications, will likely be much more cost-effective for the foreseeable future.

Ted Thayer

principal product specialist—control / Phoenix Contact USA

Options for all

Industrial companies today appreciate having a choice when it comes to controlling their facilities. One major reason is because of the constantly changing cybersecurity environment where threats to interrogate a system could cripple any facility. Private, government or military facilities must disconnect critical control systems from outside connections through air gapping to minimize the global risk an attack could bring. In addition, many locations are still developing broadband connections and wireless connectivity options. In these cases, it helps to have options that do not rely on a constantly available connection to the cloud.

Kris Dornan

marketing manager, software and control—large control/ Rockwell Automation