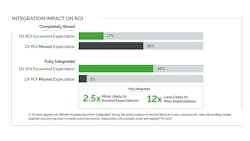

Companies whose digital-transformation (DX) projects meet expectations beat their investment goals by 50%, according to a PTC research study (Figure 1). Those companies whose projects fail miss their goal by 30%. Our research also demonstrates that DX projects are as likely to succeed as they are to fail. What can companies do to boost the prospects of DX projects?

Also read: The all-knowing digital twin

The success of any DX project rests on three pillars:

- technology must bridge the gaps

- leadership must redefine boundaries

- culture change must be driven from top and bottom.

These pillars take the form of work to be done and create a foundation for strategy development and the tactics that will flow from the strategy.

Technology must bridge the gaps

Functional siloes, such as engineering and manufacturing, must learn to talk to each other. We find that companies who use digital technology to make it possible for siloes to share data and collaborate are more than twice as likely to succeed in their broader DX initiatives. Collaboration makes it easier to leverage the data generated by discrete technology initiatives and to share that data downstream. Conversely, DX initiatives are more likely to sink when data is simply dumped on people without thought as to how that data might be usefully accessed and shared (Figure 2).

Figure 2: DX initiatives are more likely to sink when data is simply dumped on people without thought as to how that data might be usefully accessed and shared.

The idea of the digital thread, a closed loop of digital processes and information that tethers the physical and digital world to one another, has taken hold. When a digital thread is in place, organizations can create seamless, uninterrupted digital connections across functions, assets, customers, production sites, workforces and products. The right information is accessible to the right people when and where they need it. This multi-directional sharing of data, information, insigh, and intelligence improves how value is created.

Leadership must redefine boundaries

Technology alone won’t solve the problem. It is only a tool. Without process and organizational changes, transformation can’t take place. True transformation means you can’t go back, and you don’t want to.

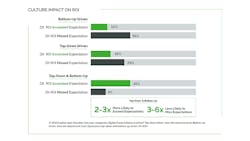

Executive support for DX initiatives is essential for transformation of any kind. Leaders aren’t championing “cool.” They’re championing a new way of creating value, demanding greater cross-functional collaboration and changes to departmental and functional boundaries. Without executive evangelism, DX projects are six times more likely to miss ROI expectations (Figure 3).

Figure 3: Without executive evangelism, DX projects are six times more likely to miss ROI expectations.

To understand the implications of this, consider that the highest-potential DX opportunities are often those where information and collaboration span organizational siloes. The professionals on both ends are human beings, as much prey to interdepartmental dynamics as anyone else. Those product-design engineers may not see that field-service data as a goldmine of insight. They may see the data’s arrival as another attempt by ignorant meddlers to interfere with the work of specialized and highly trained experts. Executive leaders must preempt this by defining a new set of shared priorities and expectations, so those relationships are recalibrated. Executives must also redefine the boundaries of siloed systems by either blurring, redrawing or eliminating.

Culture change must be driven from top and bottom

If digital transformation is a process, then culture supplies the fuel for that process to take place. Sound leadership, cross-functional collaboration and best-in-class technology are not enough. When the people who need to embrace digital transformation do not do so, the technology becomes irrelevant, and its potential for positive change is lost.

Successful cultural change comes when leadership instills project ownership at every level of the organization through top-down and bottom-up initiatives.

Top-down: Executive leadership aligns the transformation initiatives with long-term strategic goals and then measures and evaluates success.

Bottom-up: Valuable use cases live at the department level, instilling ownership and improving the key performance indicators (KPIs) that matter most to the stakeholders in these functions.

Companies that take this two-pronged approach are two to three times more likely to beat financial expectations than those who chose one or the other (Figure 4).

Figure 4: Companies that take a two-pronged approach are two to three times more likely to beat financial expectations than those who chose one or the other.

Leadership should treat DX projects as watershed moments in the company history, with the sure knowledge that competitors are doing the same. No technology can guarantee innovation, but digital transformation can certainly create circumstances where it is more likely to happen.

Will Hastings is research analyst manager at PTC. Contact him at [email protected].

About the Author

Leaders relevant to this article: