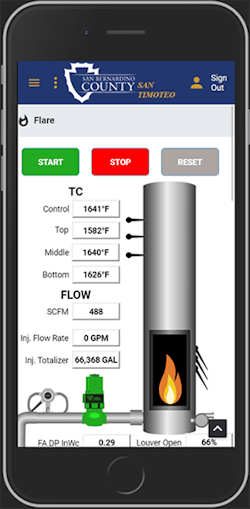

Figure 1: San Bernardino County's almost 500-acre San Timoteo landfill recently upgraded to gas monitoring and controls that manage its four blowers, flare station, pumps, valves, thermocouples and other devices with a pilot project from SCS Engineers, which consisted of 340 tags, 16 screens and more than 50 alarms monitored and managed by Ignition 8.0 web-based SCADA software, Ignition Perspective Internet software module and an Ignition Edge gateway from Inductive Automation. Source: SCS Engineers and San Bernardino County

It used to be only big-ticket, high-value applications and deep-pocketed, heavy-industry end-users could afford constant process monitoring, visualization and control. Well, times changed, prices went down, processing power increased, and now pretty much everyone can afford to gather data with Ethernet and wireless networking, analyze data with sophisticated software, and display it on ubiquitous interfaces including tablet PCs and smartphones. However, the trick is still to apply these less-costly technologies in applications and enable more effective decisions.

For instance, the 2 million residents of San Bernardino County, Calif., have generated plenty of garbage throughout the years, and just like everyone else, they also needed to find a place to put it. Encompassing greater Los Angeles, the county covers 20,105 square miles and is the largest by area in the United States—close to the size of West Virginia. All this real estate gave the county abundant options for storing its trash, and it built and presently operates about 28 landfills, including its almost 500-acre San Timoteo facility (Figure 1).

However, San Bernardino County's landfill gas (LFG) monitoring and control systems aged during the years, and its equipment grew increasingly cumbersome and difficult to use. While many U.S. landfills still manually record data such as gas levels and device runtime hours, the county had been using PLCs and touchscreen HMIs running third-party software on a virtual private network (VPN). This setup managed four blowers connected to the flare station at Sam Timoteo, and visualized temperature information from its thermocouples, as well as pressure, level and current data from related devices.

"This system was secure, but it was difficult to access," says David Hostetter, regional manager of the eight-year-old remote monitoring and control (RMC) group at SCS Engineers, a multi-disciplinary engineering, environmental consultant and contractor in Long Beach, Calif.

Simpler, streamlined SCADA

To develop and upgrade to a simpler, more capable and closely connected, and less costly LFG monitoring and control solution, San Bernardino County recently sought help from SCS, and they designed and implemented the pilot project at San Timoteo with 340 tags, 16 screens and more than 50 alarms. The landfill typically logs almost 9.7 million rows of data from 261 tags to a database. The SCS RMC pilot employed a flexible, scalable platform for desktop or mobile data access, which consists of Ignition 8.0 web-based SCADA software, Ignition Perspective software module, and an Ignition Edge gateway from Inductive.

These software and hardware components enabled San Timoteo to migrate from its less-flexible VPN to a web browser-based SCADA system with interfaces rendered in HTML 5, so they can be viewed on any-sized screen (Figure 2). Ignition Perspective not only allowed SCS to display the typical components of a regular system, it also let them embed Pix4D maps inside the web-based interfaces.

Figure 2: The SCS RMC pilot project at the San Timoteo landfill employs a flexible, scalable platform for desktop or mobile data access, which consists of web browser-based Ignition SCADA software with interfaces rendered in HTML 5, so processes and equipment such as its flare station can be viewed on any-sized screen from laptop and tablet PCs to smart phones. Source: SCS Engineers and San Bernardino County

"In addition to displaying data and status indications, Ignition software also lets the landfill's operators remotely change variables, turn its flare on and off, adjust blowers and valves, and reset alarms," says Hostetter. "We still use the VPN, but now the devices are easier to access."

In fact, because Ignition 8.0 was still in beta testing when it was installed in the pilot at San Timoteo, SCS was able to add new features during nightly builds as they approached the project's deadline. These included integrating trends and graphing functions to meet San Bernardino County's requirements and deliverables. The county also specified that the upgrade let it easily access online data without using Java, which the Ignition 8.0 Perspective module could do. Finally, the gateway established an onsite hub-and-spoke topology, and connected the site to SCS RMC’s cloud-based Ignition system to enable a complete enterprise solution.

"Overall, this improved SCADA system gives San Timoteo's operators and San Bernardino County's managers much clearer views of their landfill operations, and a better understanding of their processes and equipment status, which reduces operations and maintenance costs," says Hostetter. "In addition to remote monitoring and control, San Timoteo has gained automatic reporting functions that make it easier to understand what's going on along with the new SCADA system's remote visualization and alarms.”

Wireless and wild blue yonder: Read the rest of the article on our sister site, Control

About the Author

Jim Montague

Executive Editor, Control

Jim Montague is executive editor of Control. He can be contacted at [email protected].

Leaders relevant to this article: