4 dimensions to improve capabilities in simulation and test

Giulio Camauli is Simcenter industry lead, industrial machinery, at Siemens Digital Industries Software.

What have been the biggest improvements to simulation-software technology in the past five years?

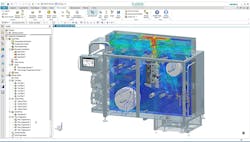

Giulio Camauli, Simcenter industry lead, industrial machinery, Siemens Digital Industries Software: Simcenter solutions allow you to model the complexity all the way from material behavior to performance of entire systems. This includes coverage for a broad range of physics including structures, flow, electromagnetics, motion and thermal (Figure 1).

Also read: Simulation sets the stage

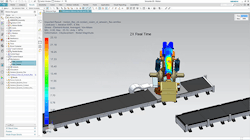

Figure 2: Simcenter includes solutions available for intelligent-design space exploration, both standalone and integrated into various simulation software.

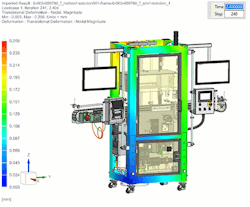

Simcenter includes solutions available for intelligent-design space exploration, both standalone and integrated into various simulation software (Figure 2). Additionally, Simcenter includes innovative new solutions or generative engineering spanning structural and fluid topologies and also system architectures (Figure 3).

Within Simcenter, we are investing resources in developing methods for reduced order modeling (ROM), workflow automation solutions and AI-driven usability enhancements as just some examples of how we enable individuals, teams and entire organizations to go faster.

Finally, we invest significantly in integrations within Simcenter and with other solutions within Xcelerator. We recognize that Simcenter exists within an ecosystem that includes many other software applications. Hence, our solutions are designed to be open and support industry standards.

Figure 3: Simcenter includes innovative new solutions or generative engineering spanning structural and fluid topologies and also system architectures.

Use of Simcenter delivers a number of benefits to customers including the ability to design and engineer better products, gain earlier insights on performance, accelerate innovation which helps them gain market share and achieve greater productivity, be it at the individual, team or organizational level.

What’s the most innovative or efficient simulation-software technology application you’ve ever seen or been involved with?

Giulio Camauli, Simcenter industry lead, industrial machinery, Siemens Digital Industries Software: Since the introduction of numerical modeling, the simulation industry is innovating constantly to bridge the gap between the virtual world and the physical world. Within Siemens, we want to enable manufacturing industries to leverage multiphysics insight in real time to support the product-development lifecycle from design to production and operations. This led to a new wave of digital twins—the executable digital twins. The executable digital twin (xDT) is a self-contained smart, connected virtual representation of a physical asset that models its behaviors and combines them with physical data to provide augmented information.

The xDT eliminates the barriers preventing simulation information from flowing across the product lifecycle. With newfound access to high-fidelity design information during operations, plant operators and facilities gain valuable insights into machine operation and status.

Manufacturers can improve energy efficiency, increase throughput, enhance quality and reduce waste by leveraging the executable digital twin across the design, production and service phases.

How has simulation-software technology benefitted from remote connectivity and networking?

Giulio Camauli, Simcenter industry lead, industrial machinery, Siemens Digital Industries Software: In addition to simulation experts and advanced users, an increasing number of project engineers and technical salespeople need access to simulation models. Those project engineers and technical salespeople need to share predictive information with their customers without expert knowledge or training in specific simulation solutions.

Within the Simcenter portfolio, we provide a solution that enables access to system simulation models without a desktop application. Identified by their logins, users only need an Internet connection and a Web browser to access models, run simulations and inspect results from anywhere in the world, at any time and on any kind of device.

Can you explain how improvements in simulation-software design and production have impacted industrial applications?

Giulio Camauli, Simcenter industry lead, industrial machinery, Siemens Digital Industries Software: Manufacturers across industries accept two common truths:

- Decisions made during the early concept stages lock nearly 70 to 80% of the development cost.

- The cost to fix defects rise as you proceed further down the process from concept to production.

Bringing multiphysics capabilities directly into the computer-aided design (CAD) environment can empower designers to make the right decisions.

Frontloading engineering: While embarking on any innovation challenge—from optimizing multiphysical behavior to adopting new manufacturing technologies like AM or even to implementing new lightweight materials, such as composites, simulating early and often is essential to avoid product failure or cost overruns.

In certain applications, frontloading requires running multiscale simulations from the microstructure level to predict performance at the macro level.

Furthermore, products today deliver their functions through the integration of mechanics, electronics and software; accessing their functionality and performance limits through frontloading is vital to deliver competitive products.

Generative engineering: Generative design has proven powerful and effective in transforming criteria and requirements into geometry and design. Companies have realized innovative designs by applying it at subsystem and component level. Generative engineering expands upon key elements of the generative-design concept to encompass an overall systems-level view of product design where computer-augmented robust design, design exploration and design-synthesis technologies combined with other AI-based methodologies such as machine learning and deep learning methods are utilized to identify optimal architectural design alternatives needed to meet complex cross-domain functional requirements.

Generative-engineering applications are diverse and include computational-fluid-dynamics-based topology optimization, using systems models to optimize system architectures and system concept generation and selection.

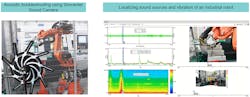

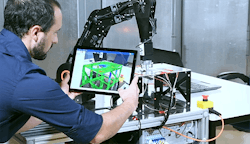

Figure 4: Consider machines on the factory floor that not only need to communicate with the machinist but with other machines, robots and maintenance operators.

Model-based engineering: Product and machines manufacturing those products comprise multiple systems: pneumatic, electric, electromechanical. To achieve the desired machine performance the interaction between different systems has to be simulated.

Consider machines on the factory floor that not only need to communicate with the machinist but with other machines, robots and maintenance operators (Figure 4). Collaboration is needed to optimize the performance of not just individual products, but also the overall behavior of these complex manufacturing systems. All this requires a model-based approach to product development.

How do simulation-software technologies figure into digital-twin platform models being used by manufacturers?

Giulio Camauli, Simcenter industry lead, industrial machinery, Siemens Digital Industries Software: Analyzing complex systems and simulation models and tuning the configuration toward optimal behavior is vital not only in the design stage but also during operation. Simulation models evolve and expand beyond product engineering:

- working together with real hardware during operation enabling improved data interpretation, reconstruction of variables and parameters during operation that is difficult to measure or not even measured.

- providing 3D visual instruction for the assembly line workers reducing errors and improving throughput

- monitoring product health in real-time, reducing unforeseen operation shutdown and performing preventive maintenance when required

- educating front-line support engineers through interactive visual 3D demos.

Digital twins can, on the one hand, enable virtual commissioning and, on the other hand, be used for rapid online diagnostics by enabling edge computing in the form of an executable digital twin (Figure 5).

Figure 5: Digital twins can, on the one hand, enable virtual commissioning and, on the other hand, be used for rapid online diagnostics by enabling edge computing in the form of an executable digital twin.

Tell us about your company’s state-of-the-art simulation-software technology.

Giulio Camauli, Simcenter industry lead, industrial machinery, Siemens Digital Industries Software: In order to take advantage of the opportunities afforded by digitalization and digital-twin technologies, companies need to mature their capabilities in simulation and test. Drawing upon our years of experience helping companies in this space, we have identified four key dimensions along which organization capabilities should evolve and mature their capabilities.

Model the complexity: One of the first requirements our customers ask for is the ability to predict/measure behavior/performance in the best possible way. This means capturing all complexity, be it from the geometry, the physics, or the usage environment, all of which can influence performance. Greater accuracy leads to greater confidence in the predictions and therefore in the decisions.

Explore the possibilities: To truly gain an advantage from investments in modeling complexity, companies need to leverage those models to run experiments. An increase in complexity also means an increase in the degrees of freedom available for adjustment. Through a systematic and intelligent exploration of the design space, they start to gain tremendous value from the models. So investments in design exploration are critical.

Go faster: The traditional pressures of time, cost and quality still apply, even as complexity increases. And increasing complexity can slow down the organization’s ability to make the right decisions. Therefore, companies need to find a way to go faster despite the complexity that they work with. This can include investment in process capture and workflow automation, cloud and high-performance computing (HPC).

Stay integrated: As product development has become increasingly complex, there are more opportunities for misalignment between teams. Development in different functional areas happens simultaneously. An optimal decision in one area could prove to be sub-optimal for another and cause delays in development or, worse, field failures. So, companies need to mature their use of solutions that help the team stay integrated across all relevant functions.

Mike Bacidore is the editor in chief for Control Design magazine. He is an award-winning columnist, earning a Gold Regional Award and a Silver National Award from the American Society of Business Publication Editors. Email him at [email protected].

About the Author

Mike Bacidore

Editor in Chief

Mike Bacidore is chief editor of Control Design and has been an integral part of the Endeavor Business Media editorial team since 2007. Previously, he was editorial director at Hughes Communications and a portfolio manager of the human resources and labor law areas at Wolters Kluwer. Bacidore holds a BA from the University of Illinois and an MBA from Lake Forest Graduate School of Management. He is an award-winning columnist, earning multiple regional and national awards from the American Society of Business Publication Editors. He may be reached at [email protected]