A Control Design reader writes: As part of a spare-parts readiness and modernization initiative at our material processing and packaging plant, I have inventoried more than 140 motors in our facility from sub-horsepower to 100 hp, and there are many more. After a preliminary analysis, my manager wants me to include opportunities to advance our green initiative, as well.

I need to identify plant-modernization projects to improve motor efficiencies. This includes updating motor-control design by adding variable speed drives (VSDs) where applicable. To start, any suggestions on integrating a controller or PLC to a VSD and motor are appreciated.

Additionally, I am having a hard time understanding which motor applications would benefit from use of a VSD. I think fans and pumps would definitely benefit, but I'm not sure how to make that decision. How do I know if adding a VSD to a fan, conveyor, agitator, mixer or rock crusher has efficiency benefits? How is the decision made? Does size matter?

I also have several process lines with six or more motors each, all running conveyors, agitators and mixers at full speed to process or convert materials. Sometimes we could just run half speed or a set-point speed, depending on demand. Some things I can slow down, and some things I cannot. How do I tie all the motors and drives together for better control?

ANSWERS

The soft start

Ideally, you would start by installing soft starts on most large motors. A soft start is a VFD hybrid with a bypass across-the-line contactor that ramps up motors to the across-the-line speed and then closes the across-the-line contactor to take the ramping module off-line. Next, keep in mind that for every VFD you install, you will have to also stock an equivalent VFD unit and that the shelf life of a VFD is relatively short—six months—until it needs maintenance to polarize the drive. Installing a replacement VFD that has not been polarized in more than a year will oftentimes cause it to explode. From an overall kindness to your stocking room and its shelf space, I would only consider VFDs on those motors that can directly benefit for other reasons than a green initiative. A soft-start module will keep your power factor in a much better state and result in less peak demand on your utility, especially around shift change, and they are simple to retrofit, assuming you have panelboard space. For smaller motors, say less than 10 hp, the case for a soft start is hard to make.

Back in the day, we used to tie a whole conveyor-line section together using a single VFD in Volts-Hertz mode. We would have a large VFD that would have several across-the-line motor starters on the secondary side of it, each one feeding a different motor. You could change the drive speed, and all of the motors would change speed together in perfect synchronization, almost like they were electronically geared together. Using this old-school method does not utilize the newer drive modes like sensorless vector mode, so the drive is a little less efficient, but you can add a dynamic braking module to the main drive, and you can gain braking capability on multiple motors at the same time with one module.

Doug Taylor / principal engineer / Concept Systems / member of Control System Integrators Association (CSIA)

Variable speed

This is a very big subject, but it’s very relevant to modern technology. What applications are good ones for applying a variable speed drive? In the old days, the acronym VSD meant variable speed device and also included such devices as adjustable gearboxes, belt shifters, wound rotor motors, eddy current clutches and anything else that could affect speed. To avoid any confusion, I’ll use the acronym VFD, if you don’t mind.

Generally, any application that requires the speed to be changed over time is a good application. An example of a VFD application is the supply and exhaust fans for air handlers. The old way was to operate a fan motor at full speed and have a damper operator that opens and closes to vary the air flow. This is very inefficient since the motor load stays high even when the damper is closed. The VFD is a perfect fit for this application. The damper is removed or blocked wide open, and now the speed of the fan is directly controlled by the VFD which controls the air flow. This reduces the load on the motor at lower speeds. There are many utilities across the United States that will help to pay for adding VFDs to these types of applications because of the energy savings. The best applications for saving are the ones that have the biggest speed change from minimum to maximum. If you run above 80% speed at all times, it might not be worth it strictly on energy savings.

Typical applications include fans, pumps, conveyors, agitators, mixers, coordinated drives and elevators.

Motors that run at a fixed speed all the time should have gearboxes to make sure the motor is running near rated load at rated speed. Many people oversize fixed-speed applications because they think, if they need 15 hp, then 20 hp is better. The mistake is that each motor draws reactive as well as real power to run, and, if you continually oversize the motors in a facility, it can affect the power factor and cause increased utility costs.

Regarding integration of VFDs with PLCs or other controllers, manufacturers these days are making their drives compatible with many different control systems. Most have Ethernet ports on them for communications to PLCs directly. All the major PLC manufacturers that sell both PLCs and drives already have a straightforward way to get all the drives communicating over the Ethernet network for start/stop, forward/reverse and speed set point. In your case, if you have any existing drives that do not have communication ports available, it is usually easy to just hardwire from the PLC outputs to the drive inputs for the same type of controls that you can do over Ethernet in the newer drives. Once you have control over the starting, stopping and the speed set point for a drive, the control becomes fairly straightforward. For the motors without VFDs, you’ll need to consider adding them. Be aware of a few things that can trip you up.

The ac “across the line” motors are full-voltage non-reversing (FVNR) motors and can regenerate back into the ac line for overhauling loads. The VFDs do not accept regenerative energy very well unless you add what is called a dynamic braking resistor or have a line-regen ac drive.

The dynamic braking resistor generally connects to specific terminals on the drive called BRK+ and BRK-. The purpose of the dynamic brake resistor is to absorb the energy created by an overhauling load. That is a load that causes the motor to actually run faster than the called-for speed you are running at. For example, if you want a large fan to stop quickly by asking the VFD to stay connected and to decelerate rapidly, the inertia of the fan keeps it spinning. This causes the VFD dc bus voltage to begin to rise. If something isn’t done in this instance, the voltage will eventually go high enough to trip the drive on overvoltage. With dynamic braking, the energy from the dc bus is dissipated as heat in the braking resistor, and the fan slows more quickly while the dc-bus voltage is maintained at a safe level.

The ac drives can run at frequencies much higher than the normal nameplate of the motor. It is not unusual to run a VFD up to 90 Hz in some applications. With increased speed/frequency you have to remember that, above 60 Hz, your horsepower stays constant but your available torque drops off. To compensate, the motor must draw more Amps to stay at the correct speed. The general rule of thumb for liquid pumps is the horsepower requirement goes up as a square of the speed, while, for an air fan, the horsepower goes up as a cube of the speed. So be careful about sizing your motor and drive, if you intend to use the extended speed range.

Scott L. Kinney, P.E. / electrical engineer / Taurus Power / member of Control System Integrators Association (CSIA)

Below 100%

If a motor will always run at 100% speed, there is no benefit to driving it from a variable frequency drive (VFD) above putting it on a soft starter. However, if a motor could perform the required task running well below 100% speed much of the time, a VFD is probably worth getting. This is true even if other throttling equipment, such as valves or dampers, must also be retained.

Variable frequency drives are more accurate and repeatable than valves or dampers and do not suffer from hysteresis

Variable frequency drives are more efficient. Power is proportional to flow multiplied by pressure; slowing a pump or fan and opening a valve or damper means the same flow may be achieved with less change in pressure. Savings can be significant, often less than half the power used with full-speed motors.

Variable frequency drives reduce wear on ducts, pipes, valves and dampers caused by excessive pressure drop. Variable frequency drives may be oversped—above 60 Hz—to increase the capacity of undersized equipment. Variable frequency drives reduce the strain on rotating parts during starts, extending life and reducing maintenance cost. And variable frequency drives draw lower amperages during starts, reducing peak loads and voltage sag on switchgear. More operational data about the motor is available without additional instrumentation. A soft start has the last three advantages, but not the others.

If a motor could be run below 100% speed, it becomes a payback period question. How long will it take for the savings from improved control, reduced power consumption and reduced maintenance to surpass the cost of purchasing and installing the VFD. That calculation is beyond the scope of a brief response, but it's usually less than two years, and often well under a year.

Size matters a little bit. Generally bigger motors offer more energy savings relative to the purchase and installation cost. Note that most equipment has a minimum speed to work properly. Integrated cooling fans and bearings with slinger rings depend on motor speed to work properly, so running too slowly will result in damaged equipment. Pumps benefit greatly from VFDs, but pumps discharging into high-pressure headers often must run 80-90% of full speed to move any fluid at all. Running too slowly will cause the pump to overheat. Pumps running in parallel to the same header must be matched and driven together. Base-loading one pump and swinging another could easily result in one pump handling all of the flow and the other pump overheating. Read more about controlling large variable-speed fans and pumps at www.controldesign.com/vsfans.

As for integration, I greatly prefer a communication link between PLC and VFDs to hardwired controls. VFDs can be configured to safely trip on loss of communication with the PLC. Redundant device-level-ring (DLR) communication is available on many models. Safety circuits—from e-stops and guard sensors—can be hardwired to discrete inputs on VFDs to work in conjunction with networked control. In addition, to run command and feedback, as well as speed reference, a communication link also gives easy access to speed and Amp feedback and many other parameters with no additional wiring, and it allows configuration of the VFD from a networked laptop.

Again, motors that would always run full speed might benefit from a soft starter, but would not additionally benefit from a VFD.

Agitators and mixers certainly benefit from running more slowly—less power usage and maintenance, plus better control over mixing. Some materials benefit from initially vigorous mixing followed by slower mixing to maintain homogeneity, while others benefit from initially slow mixing and gradually speeding up.

Conveyors can definitely benefit from VFDs. When programming them, there are a few things to keep in mind.

Ideally you control height of material on the conveyor. If you are feeding slowly, run the belt slowly. When feed speeds up, speed up the belt. The pile height will therefore remain consistent. This can be a huge help if you have a control challenge maintaining the level/weight of the equipment fed by the conveyor. With constant speed conveyors, once material is fed onto the conveyor, it's committed. But with VFDs, you can see a change in feed rate almost instantly at the discharge end because the conveyors speed up and slow down with the feeders.

Any conveyor can run at the same speed or faster than the conveyor upstream, but generally running a conveyor more slowly than the one upstream will cause problems. I've worked on some conveyor systems where the first four or five are on VFDs, but the last two are constant speed. That's fine. But there's no point in putting a VFD on a conveyor downstream of a constant speed conveyor, unless the VFD conveyor spends much of its time being fed from an alternate variable speed source.

I normally control such a system by producing a demand based on the destination equipment, and run the feeders based on the demand. Then each conveyor has an auto/manual bias station with the upstream equipment as an input. It can either follow the upstream equipment, or be set to run a constant speed. If all the conveyor speeds are in auto, they all accelerate and decelerate with the feeder. To prevent material problems, often I'll allow only zero or positive bias and force even manual speeds up to the upstream speed unless a technician is logged in.

Consider the capacity of the conveyor and motors. The limit on such motors is Amperage/torque. Many conveyors do not do well below 40-50% of full speed, so their turndown is not very flexible.

Chris Hardy / senior controls engineer / Cross Integrated Systems Group / member of Control System Integrators Association (CSIA)

Consider shelf life

There are many considerations that drive the decision to use a VFD to save energy. Since there is more potential for saving energy on high-demand equipment, it would be a good idea to index motors in terms of the highest horsepower and length of operating time. For example, a 50-hp motor that runs 24/7/365 will use more energy than a 100-hp motor that runs 8/5/288. The best strategy is to concentrate on these high-energy consumers because that is where one will get the biggest return for efficiency improvements.

One of the first things to check is the current motor loading. Many times a load is 10 hp and someone in the past put a 20-hp motor on the application, just to be safe. So now, even a high-efficiency motor running at half load will be very inefficient. Attempt to have the motor size the next standard rating above the maximum anticipated load. Then, the application will be running in the high-efficiency range of the motor.

Then next thing to find out is if there are any times the load can be run at reduced speed. If it can't, then move on to the next project. Putting a VFD on an application that always runs at 60 Hz speed will use more energy. This is because of the losses in the insulated-gate-bipolar-transistor (IGBT) power semiconductors in the drive. If the speed can be reduced, then there is a good chance a VFD would be a good fit. Essentially, an electric motor is a constant torque device, so, as one reduces speed, the energy usage also reduces.

Also, look at the load type. If the load is a machine, chances are it is a constant-torque load, and cutting the speed in half will cut the energy usage in half. If the load is a pump or fan, the loading is typically a cube function and cutting the speed in half will cut the energy usage by 7/8. One needs to pay attention to the duty cycle. If the time spent at low speed is significant, the motor cooling fan is ineffective at cooling the motor. An external fan may be needed. Inverter-rated motors will have a turndown ratio specification indicating the lowest speed the motor can run without adding an external constant-speed blower.

Lastly, PLCs and other logic solvers, sometimes onboard the VFD, can be used to monitor the system and decide when speeds can be decreased or increased. They can be used to set speeds based upon recipes. They can be perhaps programmed to turn off equipment when not being used. They can be used to match line speeds. It is common today for a drive to be controlled over a fieldbus—EtherCAT, Modbus/TCP, EtherNet/IP—connected right to a PLC. This makes control easy.

If the application does not appear to be suitable for a VFD, one can consider a soft starter. A utility power bill always has two components—an energy charge and a demand charge. While a VFD affects both because it can soft-start the load and reduce speed, the soft starter only affects the demand charge. The soft starter will start a motor direct on line (DOL) using semiconductors to limit the starting current thereby controlling the demand. When the motor is up to speed, a bypass contactor will close, shorting across the semiconductors. Because the motor current is shunted through the contactor, there is no longer an energy loss due to the current flowing through the silicon-controlled rectifiers (SCRs).

One other thing to consider is that any electronic product adds complexity to a control system. VFDs and soft starters, being power electronics, are not as rugged as a DOL starter. There will be equipment failures. Most manufacturers will cover the cost of the drive if it failed during the warranty period. However, troubleshooting, removal and re-install are generally not covered under a manufacturer’s warranty. If the process is critical, one may want to keep spares. Soft starters generally have a long shelf life. Not so with VFDs. The VFD problem centers around the electrolytic bus capacitors that filter the dc bus. When the drive is not powered, the electrolytes in the caps will migrate out of position. If power is off for less than a year, most modern caps are OK. Between one and two years, migration has started. After two years, the bus caps should be reformed. A good drives service center can perform this procedure. This problem is applicable to all VFDs with a dc bus; every manufacturer has this problem. Needless to say, just because a drive goes two years without power doesn't mean it will blow up. But it happens enough that, if it is the only unit left that will get the equipment running again, one should not take the chance and opt to reform the caps.

The most successful upgrades are done when the end user retains the services of a reputable control system integrator (CSI) experienced in the drives market. The CSI will spend the time with the various applications and recommend the best components for the particular application. Working with a vendor salesperson may work, but then equipment recommendations will consist of items they sell. For example, the application in question may need precise position control, and a vendor may only have a PLC-based motion control that is based upon velocity. Both solutions are technically motion control, but only one solution is right for the application.

Kenn Anderson / President / Nova Systems / member of Control System Integrators Association (CSIA)

Plantwide goals

There are many ways and philosophies to perform plant-modernization projects that include green initiatives. This can be difficult without a clear understanding of what equipment exists and what the true end goal is. I have more than 25 years of experience working in ammonia-refrigeration controls with energy management along with plantwide process-automation projects. Some of the key items you are asking are logical and looking down the correct path. I’ll try and break down my thought process on a project like this as best as I can, understanding that there are a lot of variables.

If the mindset and funding is the “total” plant upgrade, I would start with picking a foundation control system for the end game, instead of adding little pieces and parts as we slowly and methodically go through the entire plant and upgrade the equipment. The initial cost will be higher, but the overall savings will more than pay for it in the long run. Not to mention, the end system will be easier to maintain and expand as you go along. A good end result always results with a well-executed plan. Some base questions to ask:

- What is the big picture?

- How many motors in all?

- Are you wanting to track power utilization for specific products or functions?

- Where are they located throughout the plant?

- Can they be logically grouped into common power distribution points or product-specific applications?

- Are there safety concerns with all or some of the motors?

- Are there some loads that are critical and some that are not?

- What motors can be run as truly variable speed or can have multiple speed set points

- What kind of environment will the equipment be in—hot, cold, humid, dry, classified?

- What platform do you want to be on—Rockwell Automation, Siemens, Schneider Electric?

- Do you want to collect any performance data or have a centralized control of all the equipment, such as an an operator room?

- Do you want any data reporting, remote monitoring or remote service/access?

Let’s start with some assumptions. I would design a core control system capable of running all of my future needs or design it to be easily expanded as I go through the plant to meet my end goal. I personally prefer Allen-Bradley, but Siemens and Schneider both have more than enough capability to do the same thing. I would make a determination if I need any redundancy in my design to help to prevent unexpected or unanticipated downtime. This primarily includes processors and networks. I would use an Ethernet-based network as my communications backbone in any of the platforms. I would also look at safety concerns to determine if any of the motors need to be controlled in a safe manner. For example, if a mixer is readily accessible by an operator, we would need to consider designing the control of that mixer to a Cat. 3 level and utilize a delayed safety relay to allow the mixer to make a controlled stop versus a coast to stop.

I would start with a design/build of a centralized control system consisting of an Allen-Bradley ControlLogix platform. I would consider a large enough rack to house multiple processors and network cards to meet my end design goals. To keep costs down, I would only put in the base components I needed to start the project and plan for additional components as more of the plant came on line. I would include redundant power supplies along with an uninterruptible power supply (UPS) system and surge protection for the main control cabinet power. I would do some preliminary network design and choose a Layer 3 managed switch to be the central hub for my networked groups. From there, I would look at the entire plant and divide up the equipment/motors in a logical grouping, either by location or functionality or both.

For example, building ventilation, dust collection and overall system utilities such as chillers and fluid coolers may be one group; process and production lines may be another group, packaging and receiving may be other groups. Or you could look at general areas: shipping and receiving, production, east side of building, northwest corner—whatever makes logical sense to you and your end-control and data-collection needs. Once the plant is divided up, I would look for centralized motor distribution points to meet those needs, along with the estimated full-load amperage (FLA). Within each group, I would determine my safety needs/concerns and then identify each area as phases of the overall project. Phase I would be the design and build of the centralized control and monitoring system along with the first grouping of upgrades. I would then designate and provide preliminary budgets to the additional phases of the project based upon budgeting needs and timing.

On motors that cannot be slowed down, I would consider their overall horsepower requirements; I would be less concerned with small motors, unless they start and stop frequently. On larger motors, I would consider a soft start or variable frequency drive (VFD) for any motor 20 hp or larger. You may be able to work with your local power company and get credits based upon changing the across-the-line (ATL) starters out with soft starts or VFDs. Typically, the costs of VFDs are now below the cost of soft starts once you get above 5-10 hp when networked.

From there, I would design a panel to serve as the motor control center (MCC) for these motors, unless a true MCC is required to meet serviceability requirements. Custom MCCs can be designed and built but may or may not be a little more costly than, say, a Rockwell Automation IntelliCenter. It all depends on the overall equipment and negotiated pricing. Always force two vendors to face off on pricing of MCCs; never let one assume they are the only answer to the project, even if they truly are. It’s the only way you will get a fair price. A custom MCC is nice, because you can design it and build it to meet your exact needs. Otherwise, you will be purchasing an off-the-shelf system that has to be field-modified to meet your specific needs, such as hardwired safety interlock circuits and networking. If you go with an off-the-shelf MCC design, I would consider purchasing extra sections and empty buckets for future use. It will cost less to purchase them with the main project than to add them later. I would then design in a local ControlLogix rack or Flex I/O rack to pick up any local analog or discrete control needed within the MCC or local area. For all other motors in which true variable speed can be implemented, I would use the Allen-Bradley PowerFlex family of VFDs and design them to be networked back to the centralized control system along with the larger motor sizes. I would then implement any interlock safety wiring into the base design.

I would include all local control power distribution and networking needs within this local MCC. I would also consider a local control display depending on the need for local control of the equipment and whether local hand/off/auto (HOA) or start/stop control and indication exists or is not in the base MCC design. I would include a local power meter networked back to the centralized control system so the overall equipment power diagnostics can be monitored and trended in the central control system. If individual equipment information is needed, it can be pulled from its associated VFD or soft start. If an ATL status is needed, local power monitors can be added to pick up key components or areas of components—a set of conveyor motors, for example—based upon the overall design. If there is a need for grouping of motors on a conveyor or fan grouping that you would like to have variable, this can be done, as long as the VFD is sized to the overall FLA and not the overall hp; there is a difference. There are also limits as to the amount of motors that can be connected to a single VFD in the manufacturer’s specifications. This is typically limited to a maximum of five motors. There is also a typical maximum hp per motor, and all motors must be identical in ratings. In the past, we have found that running a 60-Hz fan or mixing motors at or around 50 Hz improves the overall amperage demand on the units without decreasing the overall performance. Of course, you would need to look at the torque curves and performance curves to see if this is accurate for your application. I do want to point out that with the consideration of adding so many VFDs to a plant, one must really consider installing line reactors on all the VFDs to prevent harmonics issues and to ensure proper installation. This includes using properly rated VFD cable and potentially load reactors based upon installation distances. These little steps will help to prevent premature failure of motors, VFDs and upstream equipment.

Once everything is determined, you can look at overall energy savings methods. Control-wise, you can monitor the peak demand of the entire plant along with the total kW usage. Knowing your peak demand charges and your kW usage, you can determine actual power bills. If you have equipment that is not critical and can potentially be shut down or scaled back, software can be developed to allow for load shedding of equipment based upon a maximum peak demand set point. As the system sees peak demand increasing to a preset threshold, key equipment can be stopped or loads reduced to curb the peak. A schedule can be developed as priority lists and allowable limits on load shedding. As a simple example, if a conditioned space is ideally 70 °F and there is a set load required to maintain that temperature but it is not critical, the conditioning of that space can be shut down or scaled back and the temperature can be allowed to rise or fall depending on the space. However, there may be a threshold that it cannot get above 75 °F. As that load shed is active, if the space reaches 75 °F, the equipment is restarted to prevent further temperature rise. You can then set up priority levels for load shedding. That space may be a Priority 1 load shed, and you may have another space or piece of equipment as Priority 2. If Priority 1 load shed goes into effect and peak demand is still not curbed after a preset amount of time or a secondary limit, Priority 2 kicks in. You can set up continuing levels to act in the same manner, although we usually limit it to five levels of load shed.

Another option to add to the list that hasn’t been mentioned is power-factor correction. This can be done plantwide with a central unit or individually at each motor. Either way, significant power-bill reductions can be realized depending on the plant and power company.

All in all, it really comes down to understanding the process, end goals and overall controllability one wants to have on the overall facility. Once you know that, it comes down to understanding whether or not there is a true payback on the cost of implementation—the return on investment (ROI). A lot of facilities that are production-based really don’t have enough flexibility in the system to allow for true energy management, or at least not one that will have a sufficient ROI. They may be able to improve a few percentage points in overall efficiency, but that may not relate into the overall bottom line. In ammonia refrigeration, we have found the most significant implementation to be in cold-storage facilities rather than production facilities. Production facilities have a base demand that cannot be modified without catastrophically affecting production, whereas cold-storage facilities have functional limits that can be manipulated to control a peak demand. Other industries concentrate more on understanding their costs by monitoring specific aspects of their plants, such as specific product lines or core utilities. That way they have a better understanding of where their costs are for accounting purposes. Every customer is unique, and every project is unique, both in the thought process and in the needs. It’s always our responsibility as an integrator to determine what that is and meet their goals.

Bradly A. Johnson / vice president, maintenance services division; vice president, industrial process group division / Dilling Group / member of Control System Integrators Association (CSIA)

Standard vs. custom

Relative to the motor, we plot efficiency curves for our motors (Figure 1). Motor efficiency peaks at approximately 4,300 rpm for this standard motor. If you had a lower-speed application, we could customize the winding so that peak efficiency happens at a lower rpm. Figure 2 is the same motor with custom winding, and now peak efficiency is happening at approximately 2,700 rpm.

Figure 1: Motor efficiency peaks at approximately 4,300 rpm for this standard motor.

(Source: Parker Hannifin)

Here’s another way to describe it. Let’s say your application required 2,700 rpm. If you buy a motor that has a rated speed of 4,300 rpm, you are not using all of the speed that the motor can provide. How are you paying for this? Essentially you now have a voltage constant (V/Krpm) that is too low, giving you more speed than you need. With a lower voltage constant, you also have a lower torque constant (Nm/Amp), so you need to provide more current relative to the torque that the application needs.

Figure 2: The same motor with custom winding now has peak efficiency happening at approximately 2,700 rpm.

(Source: Parker Hannifin)

By designing the winding more around the 2,300 rpm requirement, your voltage constant is more in line with providing you only with the speed you need. So, in this example, you could have a higher voltage constant—less speed relative to voltage provided—which would also give you a higher torque constant—less current for the torque you require.

The motor is operating more efficiently because there is no speed or torque capability that is sitting stagnant.

These types of modifications can easily be made to a motor by changing the AWG (American wire gauge) of the copper and its number of turns in the stator.

There are other things that can be done to improve overall efficiency relative to heat dissipation via rotor and stator design. But those types of considerations are usually looked at during initial product design and are not something that would be offered via a customization to an existing motor.

Jeff Nazzaro / gearhead and motor product manager / Parker Hannifin

Affinity laws

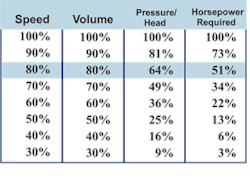

You can certainly save energy and improve efficiency by integrating drives with your motors. Pumps and fans are great targets for energy savings if you can slow them down and still perform the needed application. You have indicated that is the case, so here’s how it works.

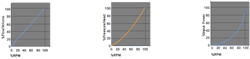

Figure 3: Due to the cubic relationship of the motor speed and the power consumed, even slowing down the motor a small amount can make a dramatic impact on energy consumption.

(Source: Baldor Electric)

Pumps are fans are considered variable-torque (VT) loads. The valuable point here is that VT loads follow the affinity laws, which really make three points.

Flow (water, air) through a VT system varies directly with the motor speed. So, if you run the motor at 50% speed, you get 50% of the flow through the pump or fan.

Pressure varies with the square of the motor speed.

Power, or energy consumed, varies with the cube of the motor speed. So, if you could run the motor at 50% speed, you would only consume one-eighth of the energy.

Figure 3 depicts the affinity laws in a graphical manner.

In fact, due to the cubic relationship of the motor speed and the power consumed, even slowing down the motor a small amount can make a dramatic impact on energy consumption.

Figure 4: Energy consumption is reduced by reducing motor speed on a VT (centrifugal pump or fan) load.

(Source: Baldor Electric)

Figure 4 shows how much energy consumption is reduced by reducing motor speed on a VT (centrifugal pump or fan) load. If you slow the motor down only 20%, you will consume half of the energy.The other applications you mention can save energy, as well, if variable speed drives (VSDs) are applied, but it will not be the dramatic impact you will see with VT loads, so I would recommend that you start with your VT loads.

Integrating the motors and drives with the PLC can be simple or complex. It largely depends on the design of your system. Integrating drives/motors with PLCs can be done in a couple of ways:

- via digital and analog I/O modules on the PLC backplane

- via industrial communication networks, such as Ethernet/IP, Modbus/TCP, Profibus-DP.

If you do choose to integrate the motors with a PLC, a program will also have to be written to control the motors and drives. The program could be quite simple or quite complex, depending on what you are trying to control. For the more complex systems, you may want to consult with a system integrator to provide you the functionality you require.

Rick Kirkpatrick / product manager, ac variable speed motors / Baldor Electric

Motor intelligence

There are VFDs that have integrated communications. Modbus RTU and Ethernet IP are the most common communication for process controls such as machines or conveyors and would communicate back to a PLC. Modbus RTU, BACnet MSTP and BACnet IP are most commonly used for building management systems that would tie in the HVAC, pumping, lighting and fire systems together for improved management. Most VFDs have the ability to communicate these protocols and have PC tools that allow for easy commissioning and configuration to the different networks. Application or communication manuals would have all of the bit numbers and descriptions for easy setup and connectivity.

There are two different application where VFDs can be used and provide the most benefit:

1. Any application where there is the opportunity for variable speed. These could be constant-torque application (conveyors, mixers) or variable torque applications (fans, pumps). Using a VFD to vary the speed, rather than mechanical devices such as a damper on a fan or a relay, you improve the reliability of the system and performance of the motor reducing any losses. You also achieve reduced energy usage, which in turn is reduced energy cost. Many regulations are requiring VFDs be used in variable-torque applications on motors that are rated down to 5 hp. Title 24 in California, ASHRAE Standard 90.1 and the 2017 DOE refrigeration legislation are all examples of these regulations.

2. Any application where you would like to communicate status on a motor and increase the protections of the motor. An example would be a critical application or pump. The VFD has built-in applications and algorithms that can provide increased protections on motors without the use of additional sensors or external devices. The list of protections can improve the life of the system and provide feedback that will help to predict when systems will fail and reduce unplanned downtime.

There is an application built into some VFDs that allows the VFD to be a master of other VFDs or motor starters. This means that the VFD can accept feedback from a demand source—temperature sensor, pressure sensor, speed reference from a PLC—and take that feedback to control other drives or communicate back to other systems based on a configured process. The communication capability increases the ability to get feedback from all systems at once with alarms, alerts and faults information with time stamps. This increases the visibility of the system and reduces unplanned downtime. It is all about bringing the intelligence to the motor.

Nicole Angiola / product manager, HVAC variable frequency drives / Eaton

Energy savings

Figure 5: Modern VFDs can reduce the motor voltage appropriately to gain those energy savings at lower speeds to follow the curves of the affinity laws.

(Source: Lenze Americas)

This really depends upon the level of control you require. If you are looking for a low-level control with just speed set point, starting/stopping and fault indication, this can be accomplished by simple I/O wiring with a few discretes or optionally a few discretes and an analog signal. If you want to be more precise and/or if you will have a controller running several drives, networking is a better way to go. Ensure your PLC and the slave VSDs support the same communication protocol. Networking gets a lot of novice users intimidated, but truly it shouldn’t. It’s very simple with modern PLCs and drives.Many, many applications greatly benefit from the use of VFDs for energy efficiency.

Let’s start by looking at centrifugal pumps and fans. Pumps and fans are sized for their maximum duty point but usually are then throttled down to a lower demand. Mechanical controls such as guide vanes, bypasses and throttle valves do present some energy savings; however, the maximum efficiency is gained by slowing down the motor directly.

These applications are referred to as variable torque applications and are governed by the affinity laws. In these applications the torque required is a function of a square of the motor speed. The power required however is a function of a cube of the speed. For example, reducing the speed to 50% can reduce the power required to 12.5% of the rated power.

Modern VFDs can take advantage of this and reduce the motor voltage appropriately to gain those energy savings at lower speeds to follow the curves of the affinity laws (Figure 5).

The simplest and least precise is to have one drive control multiple motors. You need to check with your drive manufacturer if this is acceptable for its drive to do this. In this approach you size the drive for the sum total of all motors and provide an external motor overload relay to protect each individual motor. Often drives cannot be switched to/from load without damage, so in this approach you must often select motor overloads that have an auxiliary contact that is break first/make last, and you run those all in series to a drive input configured for external fault—the idea being if one of the motor overloads trip, it first faults the drive and doesn’t allow the drive to be restarted unless all motor overloads are clear.

Another simple and still imprecise way is to command speed to one drive and then have that drive’s analog output annunciate its actual speed. Run that analog in turn to the next drive as its speed set point. You can also use the drive’s run/status output as a run/stop command to the next drive. It is imprecise, and it is very basic. Error handling of individual drives can be an issue with this method.

Another approach that can often be done—check with your drive manufacturer—is using a fieldbus such as CANopen where the nodes are peers and you would have a master drive which you command speed and run stop to via its keypad or control wiring, but then map that master drive’s status words on the network as the command words to the slave drives to have them follow the master’s state. Precision in this approach is a function of the motor control method used by the drives. Closed-loop vector is the most precise. Open loop V/Hz is the least. Error handling of individual drives can be an issue with this method.

A better way to do this is networking the drives to a PLC. The PLC can set speed and control each drive and also read each drive’s status so faults can be annunciated and controlled reactions easily set up to respond to various conditions.

Joel Kahn / product manager, inverters / Lenze Americas

ROI analysis

Many industrial plants that are in the process of implementing green initiatives or modernizing to reduce costs must evaluate the energy costs associated with motors in their plants. Motors tend to play a large part in plant efficiency and cost-reduction efforts because they are usually responsible for a substantial amount of the monthly electric utility costs. Some statistics indicate that motors consume 70% of all domestic manufacturing energy and 55% of total energy generated in America. Interestingly, most motors will consume 10 to 20 times their capital cost in energy every year so any effort aimed at reducing these costs can yield significant savings.

In many applications where motors are used to drive pumps, fans or compressors (centrifugal loads) and are using throttling, either valves or dampers to control the process flow or pressure, variable frequency drives (VFDs) may be applied to great economic benefit. By changing constant motor loads to variable speed, payback benefits may be realized in as little as one to two years.

If you are reviewing your plant for a modernization initiative, reviewing the motors in the facility is a good place to start since, in most cases, they will represent the bulk of your monthly utility payment. If these motors drive centrifugal loads like fans, pumps or compressors and the process operates below 100% flow or pressure, there may be a real opportunity for energy cost reductions. The motors are typically started with motor starters.

There are three characteristics with centrifugal loads known as affinity laws that define the relationship between shaft speed or the speed your motor is running and process parameters such as flow, pressure and power consumption.

- Flow (of material) is directly proportional to the shaft speed.

- Differential pressure is directly proportional to the square of shaft speed.

- Process power is directly proportional to the cube of shaft speed.

Therefore any plant process that requires reduced flow (air, water, oil, gas) can utilize the affinity laws. For example, if your process is rated for a material flow of 10,000 gallons/minute (gpm) but can be operated at a reduction to 7,000 gpm or a 30% reduction in flow, changing the motor speed may yield impressive energy savings. From the affinity laws we know flow and speed are directly proportional, so if the motor speed is reduced by 30%, the process flow will also drop by 30% (10,000 gpm to 7,000 gpm), but the energy consumption is a cubic function, so the amount of energy used drops even more; and, in this case, a 30% reduction in motor speed yields a 66% reduction in energy usage. This approach can also work on many systems where speed is adjusted such as agitators, mixers, conveyors and mills, and these typically will also benefit from more precise speed control.

As long as the plant process is using a centrifugal load that is being throttled or controlled with dampers or valves, it is likely that the process can benefit from the addition of a VFD. This argument applies for low-voltage and medium-voltage motors. Other applications may also benefit but may require additional analysis and may not yield the same energy cost savings.

When evaluating a motor system as a candidate for a VFD, one should look at the turn-down speeds. As stated above a 30% reduction of speed yields large energy cost savings. In processes where the speed turn-down rates are less than 90%, then the viability and payback of adding a VFD becomes less clear. If the process runs close to 100%, then the cost savings of the VFD may be minimal and possibly eliminated by the efficiency of the VFD itself. By adding a VFD, the VFD itself has a rated efficiency, typically 95% to 97%, and adds losses to the overall system. The savings associated with the operating speed reduction must be greater than the efficiency losses of the VFD. One note here is that there is no such thing as a 98% or 99% efficient drive. These numbers are bandied about and usually represent only the inverter section of the VFD. Although they are true, they represent only one section of the entire system and not the actual VFD components required to run. Most VFDs today operate with 3% to 5% losses for the entire VFD end to end. Sometimes, input filters, sine wave filters and output filters are not included in this efficiency rating as they are separate from the VFD but are still required. The VFD user must be aware of all components required to safely operate the VFD to protect the plant from unwanted harmonics and to protect the motor from insulation failure, harmonics and bearing currents leading to premature motor bearing failures. The VFD manufacturer should work with you to develop a wire-to-shaft overall efficiency rating to clearly define the actual losses and to identify the installation requirements for filters, additional cabling connections and mounting pads for various separate components outside the VFD cabinet.

In addition, most VFD manufacturers will work with the process plant to identify the potential costs savings and generate ROI payback periods. These can include not only the energy saving associated with the VFD operating at reduced speeds but could include additional HVAC costs—additional control room air conditioning—but also plant requirements like site arrangements.

There are several other advantages to installing VFDs on motors which are harder to quantify but, nevertheless, very real advantages. The use of a VFD eliminates the starting inrush event that the motor experiences. This has two advantages.

First, the elimination of the inrush current when starting the motor, which can be six to 10 times the motor FLA rating, has the effect of reducing the peak demand charges on the monthly utility statement. Obviously, the cost savings is dependent on the number of motor starts but eliminating this phenomenon should have a positive cost impact on reducing the peak demand charge on the utility statement. Secondly, the elimination of the inrush event dramatically reduces the mechanical and electrical stress on the motor leading to longer motor life and lower maintenance costs. However, this may be negated by the selection of a VFD with an inferior output waveform leading to harmonic heating or insulation damage in the motor, so care must be taken in the VFD topology selection. The addition of output filters to protect the motor leads to reduced efficiency, which adds cost and possibly plant power grid and safety issues (motor self-excitation), which must be analyzed and accounted for. These issues can easily be overcome but may yield a longer payback period, as well as additional operating expenses if the plant power grid is changed.

Lastly, most modern VFDs will present a constant power factor to plant power grid of 0.95 or greater, which will tend to reduce the power factor penalty on the monthly utility statement. This is a small charge and is at most a secondary effect of the VFD. However, care should be taken with older-style current source drives where the power factor is proportional to speed and can become very poor when operating below 80% speed, potentially requiring the addition of power-factor correction components in the plant. This adds installation costs and possibly reduces efficiency, which again can increase the anticipated payback period and energy savings.

The discussion presented here applies to low-voltage or medium-voltage motors and their applications. Any VFD manufacturer should be able to assist the end user, engineering firm or electrical contractor with the ROI analysis. Understanding the operating scenario and examining the plant single line should be within the scope of the VFD manufacturer’s expertise and part of the proposal process. Additionally, the VFD manufacturer should be able to evaluate the plant motor, especially if it is an older, existing motor to verify proper operation and motor life with the selected VFD.

Mark Harshman /director of system engineering / Siemens

3 steps to efficiency and payback

Blindly adding a VSD will not automatically increase the efficiency of an axis (drivetrain + motor + VSD). VSDs have power losses and could worsen the overall system efficiency. Determining efficiency increases and fastest payback rates can be summarized by the following generalized process.

1. Does the application run at the motor's "full speed" and seldom start and stop? If the answer is yes, then adding a VSD will hurt system efficiency and simply add losses (VSD losses and motor PWM heating). Replacing the motor with a higher efficiency version is the best option. Determine if the motor should be replaced now or later based on current age of the motor, new motor cost and energy savings payback rate. Fans and pumps typically fall under this category.

2. Does the application run at the motor's "full speed" but also starts and stops often? If the answer is yes, then a VSD can reduce motor starting currents. The bigger the motor, the more reduction in current spikes (line start currents are typically six times motor rated current). The payback rate is determined by how often the motor starts and stops and how large the motor is. You can also replace the motor with a higher efficiency version, but check with the VSD manufacturer. High-efficiency motors may require an upsized drive due to the low winding impedance.

3. Would the application be better suited running slower or faster than motor line speed? If the answer is yes, then you will need a VSD, or perhaps a gearbox change, but be aware changing the speed of the axis can affect required torque and power. For example, saws that run slower have dramatically higher torque. Increasing fan speed increases motor load quadratically and can be mechanically dangerous.

If you are converting a whole line to variable speed and it can mechanically handle it, there are typically two control schemes: velocity-follower and electronic gearing.

Velocity-follower systems can be thought of as open loop controls running at 50% or 70% speed. If an axis that is commanded to run 70% speed can run at 68% or 71% without issue, then this type of control can be used. In the olden days, the master axis would have an analog output that was wired to the analog input of the next axis. More modern systems can use a fieldbus control and send digital commands to each drive.

Electronic gearing is required for applications that have some type of registration—closed loop, shaft lock. These are closed-loop systems that can maintain shaft angle relationships as if there was a mechanical line shaft running the whole machine. It is easiest to control these systems with a realtime fieldbus like EtherCAT where each axis can receive the master axis position over the bus instead of running encoder cables between each drive.

Scott Cunningham / product and application manager, controls and automation / KEB America

Reduce cost, increase control

To answer the first part of your question, you should start by looking at applications where there’s a need to control the speed of the motor that is currently being controlled by mechanics, a contactor for starting and stopping or older variable-speed drives. There are benefits that come with using the variable-speed drive for starting and controlling the application and ways to improve not only the efficiencies of the application and the way it’s running the motor, but also the overall process. Product waste is an area where improved control of the motor and application can reduce product or material waste, making the process and the plant more efficient and saving costs.

Using a variable-speed drive, with or without a PLC, in an application is accompanied by significant benefits. Those include improving the efficiency of the system, reducing waste, reducing maintenance cost and having better control of the application. A lot of times, people think that you're just adjusting the speed, but in reality you’re reaping a lot more benefits than just having variable speeds to run the motor at.

In terms of which motor applications would benefit from a variable-speed drive, you need to ask yourself, “Does the application run at 60 Hz?” That's typically the base speed of a motor in North America. If the motor is currently running at 60 Hz, day in and day out, then the application may not benefit from the variable-speed control but would benefit when starting the motor and from the feedback the drive can provide on the application.

If it's not running at 60 Hz because it's being adjusted by mechanics or other equipment in the system, or if there's a lot of starting and stopping, those are the applications where we would look at easily applying a variable-speed drive. Any time you're not running at a base speed all of the time, if there are any adjustments being made, that's where variable-speed drives help out. Variable-speed drives provide precise speed control. If you use a VSD, you can reduce the inrush current when starting and the amount of power to get things moving just by the nature of using the variable-speed drive.

When it comes to tying all the motors and drives together, you’re getting at the heart of where variable-speed drives integrate best in the process. Installing a VSD here gives you the benefit of unlimited speed points, so you can adjust speed to whatever value you need for your application and coordinate the movement of product. You can also better control those applications and eliminate any kind of waste.

There are two ways of going about controlling the process line, depending on how much control is needed. There are settings and application-specific setups within the drive, as well as some additional programming that can be dealt with. Drives handle a number of different applications, so the control can be as simple as being the default programming of the drive, configuring the parameters to increase control of the application while using the drive’s inputs and outputs or going to a controller or PLC to work with a number of different drives.

Using a controller or PLC to communicate to drives and the different pieces of equipment to control them and to receive the data back can increase the number of drives being controlled at one point all from a central location. One of the major benefits of a VSD is the data it collects. Not only are you controlling the application, but you receive information about the process and the application. You can analyze how much power you’ve been using and use the data you receive to understand what’s going on in the application and help you to identify any issues to improve overall system efficiency.

Adding variable-speed drives to your applications can provide significant benefits in terms of reducing waste and maintenance costs, increasing control and improving efficiency across the board.

Jim Kluck / senior product marketing manager / Danfoss Drives

Energy savings

Efficiency is usually a derivative of cost up front. This is where the interest of equipment supplier and user can vary. Every industrial application can be made more efficient, so it generally comes down to how much work it’s going to take, how much money it will cost and when I can expect the efficiency savings to pay back the investment.

The first scenario for motors running across the line is going to a more efficient motor. Government regulations are mandating new motors installed meet minimum efficiencies that continue to increase. Today’s premium-efficiency induction motors have a very high efficiency, but motor manufacturers are approaching the design limits to how much more metal or copper they can put into the motor to make them more efficient before the frame size will increase.

The next scenario is changing a fixed-speed application to a variable speed with a variable-frequency drive (VFD). For variable-torque applications, such as a fan or pump, this is typically a no-brainer as the payback from energy savings is very short if you can run at reduced speeds. A precaution I would give is to verify the motor is designed to be run from a VFD. There is also an emerging trend for variable-speed applications to use a synchronous motor as they offer even higher efficiency with smaller footprint.

There are also numerous VFDs and servo drives that offer energy-saving functions and configurations. A few typical functions are ECO mode to reduce motor losses; bypass mode to reduce inverter losses; and hibernation mode to go into sleep mode during long pauses. Since motors can generate energy when stopping or with overhauling loads such as cranes using drives that can regenerate energy back to the power supply are preferred for certain applications. On production machines with multiple drives a common dc bus arrangement is very popular to take advantage of energy sharing when one or more motors are generating power and other motors can utilize this power.

This is also a good time to mention that hydraulic and mechanical solutions are being switched to electrical solutions due to the high potential for energy savings. A hydraulic pump with a fixed-speed application can be replaced by a servo pump that supplies energy only when required and can save up to 70% the energy consumption. Even replacing a gear box or pulley with a direct drive can result in large increases in system efficiency, so using a holistic approach to energy savings is always best.

For payback calculations, I would use one of the many free software tools available from motor and drive manufacturers to help to compare savings with different solutions and help to validate the payback is expected on your investment.

Craig Nelson / senior product manager / Siemens Digital Factory

ALSO READ: How to select a variable frequency drive

Mike Bacidore is the editor in chief for Control Design magazine. He is an award-winning columnist, earning a Gold Regional Award and a Silver National Award from the American Society of Business Publication Editors. Email him at [email protected].

About the Author

Mike Bacidore

Editor in Chief

Mike Bacidore is chief editor of Control Design and has been an integral part of the Endeavor Business Media editorial team since 2007. Previously, he was editorial director at Hughes Communications and a portfolio manager of the human resources and labor law areas at Wolters Kluwer. Bacidore holds a BA from the University of Illinois and an MBA from Lake Forest Graduate School of Management. He is an award-winning columnist, earning multiple regional and national awards from the American Society of Business Publication Editors. He may be reached at [email protected]

Leaders relevant to this article: