Motion and energy drive performance characteristics

Nathan Eisel is national product development manager at SMC of America.

Sol Jacobs, is vice president and general manager at Tadiran Batteries.

Art Holzknecht is the engineering manager at Hiwin, a global manufacturer of mechatronic components and systems. He has more than 25 years of experience in precision engineering and motion control system development. Over the course of his career, has held roles in engineering design and management, program and product management and business development. Art has designed and implemented mechatronic solutions for a wide range of industries, including semiconductor and electronics manufacturing, genomics and life sciences, factory automation and robotics. He holds a BSME from the University of Michigan at Ann Arbor.

What are three key things that a machine builder, system integrator or manufacturer should know about your organization?

- where am I?

- what am I?

- am I well?

All of this is backed by a true global presence with manufacturing throughout the Americas, Europe and Asia, making SMC the obvious choice for today’s new machine designers.

We have series of more than 12,000 products to choose from so that design engineers from all industries can find products to suit their specific requirements.

We manufacture a diverse portfolio of automation components, and we use these in our own mechatronic motion system products. This includes linear servo motors, direct-drive torque motors, linear and rotary stages, servo drives and multi-axis motion controls. We integrate these components into complete multi-axis motion systems for OEM and applications in a range of industries, including life science/drug discovery, electronics manufacturing, factory automation, precision assembly systems and packaging, to name just a few markets we serve. With millions of dollars of inventory centrally located in Chicagoland, we can ship quickly.

From components to complete mechatronic systems, we offer our customers one of the broadest ranges of solutions for their automation applications. We can provide product solutions at the level that is most economical and efficient for the customer.

Through innovative R&D and many decades of manufacturing expertise, Tadiran has established and refined proprietary processes and protocols that enable bobbin-type LiSOCl₂ cells to achieve an incredibly low self-discharge rate of just 0.7% per year to enable up to 40-year battery life. By contrast, lower quality bobbin-type LiSOCl₂ batteries experience a high self-discharge rate of up to 3% per year, which makes 40-year battery life impossible. In addition, Tadiran manufactures a family of industrial-grade Lithium-ion (Li-ion) batteries that can operate for up to 20 years and 5,000 recharge cycles, whereas consumer grade Li-ion batteries can only operate for roughly five years and 500 recharge cycles.

Tadiran primary LiSOCL₂ batteries and rechargeable Li-ion cells are capable of delivering the high pulses required for two-way wireless communications, ensuring reliable connectivity to the IIoT.

What new technologies are driving product development and why?

How does the Industrial Internet of Things figure into business strategy?

Figure 2: Oceantronic's GPS/ice buoy is being used in the Arctic for use in experiments measuring wind, temperature sunlight and ice thickness near the North Pole. (Source: Sigrid Salo NOAA/PMEL)

How will machine automation and controls alter the way companies staff their operations in the future?

How is the development of software solutions impacting requirements for hardware?

As engineering and IT continue their convergence, which one is and/or will be leading the direction of future automation and technology?

IIoT and Industry 4.0 are still in their early stages of adoption. As the benefits of these technologies are realized, engineers will develop more products to take advantage of the benefits for their customers. This will lead to more demand for IT solutions to support them, leading to more product development in a virtuous cycle.

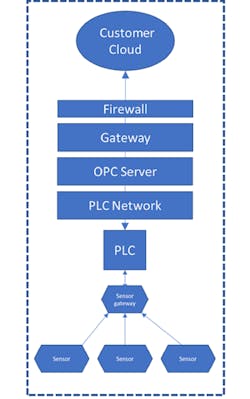

Figure 3: The integration of both IT and OT is integral. This chart is a generic representation of a production machine and the location of different technologies.

Looking into the future, how will technology change your organization or other organizations over the next five years?

Figure 4: Workflows are changing to adapt to the benefits of automation, yielding benefits in terms of increased productivity and higher quality, while also reducing product lead times and controlling costs.

In manufacturing, advances in robotics and automation will continue to increase their deployment. Demand for more sophisticated motion control to automate complex processes will grow. High automation content in manufacturing reduces the need for unskilled labor, which helps to control costs, improve quality and enable advanced economies to compete with developing countries with a large pool of low-cost labor. Advances in automation technologies are a key enabling element for this.

ALSO READ: Pneumatic vs. hydraulic vs. electric linear

Mike Bacidore is the editor in chief for Control Design magazine. He is an award-winning columnist, earning a Gold Regional Award and a Silver National Award from the American Society of Business Publication Editors. Email him at [email protected].

About the Author

Mike Bacidore

Editor in Chief

Mike Bacidore is chief editor of Control Design and has been an integral part of the Endeavor Business Media editorial team since 2007. Previously, he was editorial director at Hughes Communications and a portfolio manager of the human resources and labor law areas at Wolters Kluwer. Bacidore holds a BA from the University of Illinois and an MBA from Lake Forest Graduate School of Management. He is an award-winning columnist, earning multiple regional and national awards from the American Society of Business Publication Editors. He may be reached at [email protected]

Leaders relevant to this article: