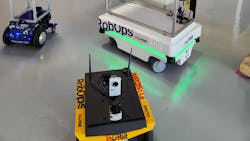

Multiple robots from different manufacturers require orchestration

The use of robotics in areas such as logistics and supply-chain operations has increased dramatically. This trend has been driven by the need for companies to improve productivity and efficiency in order to remain competitive. As a result, logistics and supply-chain companies, from consumer brands and retailers to third-party logistics companies (3PLs), are at the forefront of integrating autonomous robots into their operations. However, as they add more robots across multiple sites to tackle a growing number of tasks, they face increased complexity and coordination issues, which jeopardize the productivity gains that can be achieved through these solutions.

One of the key challenges faced by logistics and supply-chain companies is the lack of robot interoperability. In the manufacturing sector, this has been largely solved for several decades through the use of programmable logic controllers (PLCs)—a type of industrial control system that allows machines to communicate with each other and operate seamlessly, regardless of the manufacturer. PLCs use a common language, such as ladder logic, to control the actions of robots, sensors and other machines.

By standardizing the communication protocols and programming language used by different machines, PLCs enable interoperability in factories, making it possible for machines from different vendors to be integrated into a production line. This includes automatic guided vehicles (AGVs), which are mobile robots that typically follow magnetic lines or other fixed infrastructure to move material within a site, for instance bringing parts closer to where they are needed.

On the other hand, advances in technology have resulted in an explosion in the potential applications for robotics. Autonomous mobile robots (AMRs) can move freely and plan their path without the need for changes to their environment. Computer vision-guided industrial arms can pick mixed items out of a bin at speeds approaching what humans can do. The potential is higher; however, these technologies are significantly more complex and rely on advanced artificial intelligence (AI.)

To be successful, robot developers must focus on developing highly specific solutions and ensure that their robots operate optimally in carrying out the tasks they were designed for. For example, a solution designed for transporting pallets would not work to manage a different type of robot, such as a robotic put wall or a floor scrubber. Therefore, it is not feasible to expect a single manufacturer to develop and commercialize robots for every possible use case. This means that end users are likely to purchase robots from multiple vendors, each with their own proprietary software.

Supply chains, with their need to adjust quickly to changing demands, require a higher level of flexibility than is possible with this legacy technology. As companies look to deploy autonomous mobile robots, cobot arms and computer vision-guided systems for a variety of functions, the current lack of interoperability results in a slower uptake. End users would like the ability to mix and match robots as they see fit, including the ability to coexist with technologies such as AGVs.

There have been some recent efforts to address interoperability issues in robotics. For example, the VDA-5050 and MassRobotics AMR interoperability-standard initiatives provide a technical mechanism to exchange data between robots. Open robotics middleware framework (RMF), which is tightly connected to the robot operating system (ROS), seeks to manage multiple robots operating in environments.

Each of these technologies also has its limitations. For instance, VDA treats AMRs more like their less-capable brethren, the AGVs that are more familiar to the automotive industry. MassRobotics can report the position of robots but cannot be used to assign them tasks. Open RMF is designed for specific environments and may not scale to situations with real-time path optimization across dozens of robots.

What end users really need is scalable, multi-vendor orchestration that allows different types of robots to work together. Robot orchestration software provides a solution to these issues, allowing companies to seamlessly integrate robots from multiple vendors and adapt to changing business needs (Figure 1). This software provides a unified interface that allows all robots to work together as part of a single operation. This means that companies can purchase robots from different vendors and still ensure that they work together efficiently and do not interfere with one another.One potential use case for robot orchestration is integrating robots with the warehouse management system, other enterprise software like labor management systems and fixed infrastructure such as cameras, doors or lifts. Rather than spend months creating a custom solution that connects a specific robot to a particular piece of equipment, orchestration would allow the end users to try different robots until they find the one that best fits their needs.

Another case is managing warehouse robots that perform different types of missions. End users may purchase robots from multiple vendors, each with their own proprietary software, making it difficult to coordinate their actions. For example, a mobile robot may be responsible for transporting pallets, while a fixed robot takes care of depalletizing and yet another robot handles item put-away. A warehouse orchestration system can improve the overall efficiency of the warehouse operation, as the robots are able to coexist, coordinate their behavior and ultimately collaborate on an optimal end-to-end workflow.

Finally, robot orchestration can help companies adapt to changing business needs. As companies grow and expand, their robotic operations need to evolve, as well. Orchestration software can provide the flexibility needed to quickly reconfigure robotic operations to meet new demands. For example, if a company decides to change the layout of its warehouse, the orchestration software can be used to quickly reconfigure the flow of goods and the operation of the robots to match the new layout.

Florian Pestoni, co-founder and CEO of InOrbit, will present " The Growing Need for Robot Orchestration" at 1:30 pm on May 23 during A3's Automate 2023 in Detroit. Contact him at [email protected].

Register for the conference at Automate Registration.

About the Author

Florian Pestoni

InOrbit

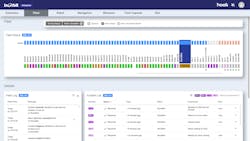

Florian Pestoni, founder and CEO of InOrbit.AI, will present “The Future-Proof Supply Chain: AI-Powered, Data-Driven and Software-Defined” at 1:30 pm on May 13 during A3's Automate 2025 in Detroit. His presentation will include an explanation of InOrbit Space Intelligence, a software platform designed to leverage the power of physical AI, robotics and system integrations to deliver a holistic view of automation.

Pestoni is an accomplished business leader and author, with a track record of bringing innovative products to market. As founder and CEO of InOrbit.AI, he leads product strategy, fundraising and go-to-market activities. Since starting InOrbit, Pestoni has become a key voice in the robotics industry, with a large following on social media. He is passionate about raising awareness around the growing role of robotics and artificial intelligence in people’s lives.

InOrbit.AI is focused on AI-powered robot orchestration, helping enterprise customers across industries efficiently manage smart robots at scale. Physical AI is accelerating growth in robotics as a new autonomous workforce, and InOrbit provides the common platform to make robots work better together. InOrbit Space Intelligence integrates spatial and operational data from every robot with a semantic environment model and line-of-business data, such as orders and inventory, to execute physical business processes efficiently in the real world.

Pestoni also co-founded the Robot Operations Group, a community-led organization with more than 300 members that organizes regular meetings and global conferences to develop and share the best practices for robot operations. In addition, Pestoni represents the United States in the ISO (International Organization Standardization) initiative to create a common mechanism for mobile robot communication; he is also leading the working group of the ARME Interoperability Initiative defining common mapping semantics and practices.

Under Pestoni’s leadership, the InOrbit Robot Space has become a hub for robotics and community engagement in the heart of Silicon Valley. Besides being a live showcase of a global ecosystem of InOrbit partners who contribute their robots to show how they can work together, the Robot Space hosts events for industry leaders, entrepreneurs, investors, academics and students who are exposed to the latest AI and robotics technologies.

Pestoni holds an MSEE from the University of Buenos Aires and an MBA from UC Berkeley. Prior to InOrbit, he worked at technology companies such as Microsoft, Facebook and Adobe, as well as startups and research labs. He holds more than 30 patents, with work on diverse areas such as image processing, cryptography and embedded systems. Contact him at [email protected].

Other articles by Florian Pestoni include:

Leaders relevant to this article: