Enhancing manufacturing efficiency with dynamic lighting

Flexible manufacturing systems, in which changes can be made quickly when product variations are introduced, have become essential for manufacturers, ensuring their ability to produce a wide range of products rapidly and cost-effectively.

While implementing flexible manufacturing systems can improve the overall equipment effectiveness (OEE) of a factory, it involves integrating many different technologies. Machine vision and robotics, for example, are configurable, flexible and programmable tools that can help to increase output and enhance efficiency.

Machine-vision systems comprise several interconnected components on both the hardware and software sides, including illumination, a key requirement for imaging; and flexible manufacturing systems need flexible lighting options.

Imaging needs illumination

Flexible manufacturing systems are driven by competition, cost, time to market, customer schedules and product requirements, regulations and certification requirements and supply chain optimization. Put more simply, factories need to achieve lean, agile and highly flexible manufacturing processes.

Any machine-vision system requires energy from the electromagnetic spectrum—light whether visible or non-visible to capture images. Using ambient light will typically result in failure, as it is unpredictable and cannot be customized for specific imaging requirements. Well-implemented illumination creates repeatable contrast between features of interest and their backgrounds and can help overcome wide ranges of part variation, position variation and even changing part types to achieve imaging reliability and flexibility. Illuminating a vision system requires different lighting dependent on the inspection item and task being performed.

Lighting may be integrated directly into imaging devices such as smart cameras, barcode readers and advanced 3D imagers, including structured light, laser scanning or time-of-flight models. Another option, static illumination, represents a more traditional design approach that uses one or two fixed geometries, wavelengths, intensities and strobe durations. Static illumination can overcome small part and positional variations and remain a viable alternative for many applications. Specific lighting components may include bar lights, panel lights, ring lights or lights with overdrive strobe.

In flexible automation environments, a high degree of part and process variation may make it difficult to implement a static illumination design. In those cases, dynamic illumination configurations—where illumination geometries, wavelengths or intensities can be configurable and changed over short production runs of widely varying parts—offer an alternative.

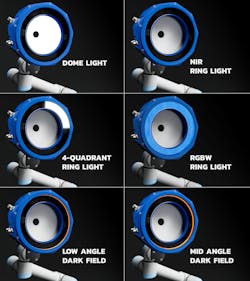

For example, deploying a single compact, multi-functional unit that combines six lights in one—a dome light, low-angle dark field ring light, mid-angle dark field ring light, RGBW ring light, four-quadrant ring light and an NIR ring light—provides flexibility. These lights feature a sequencing controller, four-zone multi-drive LED driver and cables, offering advanced control capabilities for complex assembly and inspection tasks.

In addition, the lights feature two expansion ports that offer the ability to incorporate other external lights with fully integrated control using a single graphical user interface (GUI).

From electronics inspection to deep learning

Certain fixed electronic inspection applications can present a unique set of challenges for a static lighting setup. Inspecting diverse components on widely varying and high-density PC motherboards involves several tasks, including ensuring there is no damage to the sockets or pinks, presence/absence checks of key components, assembly verification, solder quality verification and optical character recognition.

With so many features, surfaces and imaging angles, the lighting requires different illumination geometries and colors across multiple camera fields of view and working distances. Deploying a multifunctional lighting unit on a collaborative robot’s end-of-arm tooling delivers the ability to use multiple cameras and illumination sources via interchangeable tooling that can be picked up by the cobot on demand during the inspection process.

Deep learning-based inspection systems can also benefit from the use of dynamic lights. These applications require clean, labeled data in the form of high-quality images. Acquiring images with sufficient contrast, which will be used to train an artificial-intelligence model, relies on the right lighting.

In certain applications, deep learning-based systems may perform multiple inspections of a single product, requiring a different lighting setup for tasks such as checking shape, size, orientation and presence/absence. Dynamic lighting covers multiple wavelengths and lighting types, providing systems integrators or OEMs with flexibility when it comes to capabilities, space and cost.

Dynamic, multifunctional lighting units may also be used for high-speed illumination of packaging in scan tunnels or palletizing and depalletizing environments, or as illumination for a photometric stereo implementation, such as where the system captures multiple images of a tire sidewall to show difficult-to-see features like black-on-black codes on the tire sidewall.

Steve Kinney is director of training, compliance and technical solutions at Smart Vision Lights. He is also a board member at the Association for Advancing Automation (A3). Contact him at [email protected].