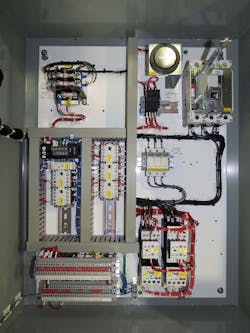

Figure 1: This configurable control panel is designed to operate small to large central vacuum systems.

Source: Northwind Air Systems

"Creating a configurable control cabinet reduced engineering and delivery time by nearly 50%," says Kevin Weaver, president at Northwind Air Systems, manufacturer of the DuroVac brand of industrial vacuums in Mississauga, Ontario. Weaver collaborated with engineers at Eaton over about four months to create a proprietary software application that simplifies the sales, quoting and ordering process and helps expedite the design, engineering, drawings and delivery of the control cabinet for DuroVac’s industrial central vacuum systems.

"I set out to create a system that could quickly configure and cost a control cabinet and the equipment to meet specific application requirements,” says Weaver. "We developed a configurable motor starter control cabinet with set costs and set discrete relay logic and drawings that are created based on options selected during the sales quoting stage with the design controlled by AutoCAD and proprietary software (Figure 1). Simply add the options, and drawing layers are toggled on or off in the AutoCAD drawing, creating drawings instantly. This led to a 10-day improvement in our ability to give approval drawings to our customers—10 days faster than basically anyone else in the world."

Since its inception in 2000, Northwind ships hundreds of 10-to-250-hp vacuum systems each year (Figure 2). Most custom fabricated systems are shipped in six weeks, including fabrication drawings.

Configuring for waste pickup

"DuroVac supplies vacuum cleaners for picking up the waste material on the floor, container, pit or bin that is not commonly reclaimed," says Weaver. "One industry that is served is fracking, where the vacuum picks up sand with chemical additive. The vacuum works well as a labor-saving, back-saving device to pickup the heavy sand. Similarly, in a foundry that uses sand castings, there is typically four or five tons of sand collecting in pits that must be picked up daily. Collecting coal from the coal gallery or the waste fly ash is another common application. There are many other applications that require a vacuum with industrial capabilities that can pickup 2 to 12 tons of material per hour. We like to see snow drifts of material in our customer's plants because then we know we have a good customer."

DuroVac designs and assembles industrial vacuum cleaning systems including large industrial portable and large industrial central vacuums. "The configurable cabinet is used in the central vacuum systems," notes Weaver. These multiple motor systems include the main motor in a range of 8 to 75 hp. Up to two auxiliary motors in the range of ½ to 5 hp are also a part of the system's configurable design. These auxiliary motors are for accessories such as a cooling fan for the optional sound enclosure and for one of five or six choices for a discharge valve such as a rotary air lock."

Figure 2: This central vacuum system is used in a wide variety of industrial applications and is capable of picking up 2 to 12 tons per hour of material.

Source: DuroVac Industrial Vacuums

These central vacuums are controlled by relay logic but are sometimes tied in to a PLC, explains Weaver. "We have relatively simple control,” he explains. “Often a remote start/stop along with a general fault indication is used. Also, on our filters differential pressure, for instance, we can have a 4-20 mA analog output going to a PLC or plant DCS."

The panels that DuroVac buys from Eaton are relay logic panels that cover 80% of the operations, says Weaver. "Eaton is providing the engineering, electrical components and assembly for the control panels used with Northwind’s DuroVac industrial vacuums systems," he explains.

Configuration options

"Approximately three years ago, DuroVac developed a project where our vacuum equipment would become configurable," comments Weaver. Selection of the vacuum pump leads to options such as a sound enclosure and inline safety filter. "There are a number of options surrounding that particular pump,” explains Weaver. “The pump hp or vacuum flow rating is also selectable, changing all of the bolt-on options. A vacuum pump may support a 20-, 25- and 30-hp motor with the only differences being the belts and pulleys."

The filter must be sized based on the pump and the material that’s being vacuumed. “There are many combinations of options such as without an inline filter, with inline filter or with a HEPA filter", continues Weaver. "Then there are options for filters that self-clean or that are manually cleaned. The filter can have high-level, temperature switches. There are then five different types of discharge devices and the devices can be several sizes. These options are bolt-on options.”

The options continue with filters with several types of efficiencies, such as a standard filter or an upgraded HEPA filter for silica sand applications to protect operators from silicosis, a lung ailment due to long-term exposure to small amounts of silica dust.

Also read: Control Panel Build More Efficient In-House

The options are many. "The key here is that, in the OEM vacuum industry, once you establish your vacuum system capability and the filter capability, the types of things you are doing on every system are the same, except every system can be completely different," says Weaver. The options for every system are similar, but they configure together in thousands of different ways.

"For example, a 15-hp vacuum package with an inline filter, coupled with a self cleaning main filter, rotary air-lock discharge and a high level sensor on the filter is a typical package," says Weaver. "We can do the exact same package tomorrow, but it's a competitive bid, and it's not an abrasive application, so the safety inline filter and high-level sensor can be deleted. This different configuration, deleting the filter and level sensor, changes the schematic, purchased parts and the control panel."

Precision costing and configuration

"In the past, when the control panel changed, the control panel description and configuration would need to go out for bid at a panel shop," states Weaver. The panel shop will review the configuration and create a quote in a few days. Then you could quote the customer. Many do it that way in this particular OEM industry. Many times that leads to guessing to cut the corner. It's going to cost about what it did last time, so you just estimate the price and figure out how to build it later. It is a close guess."

So, Northwind created a software package that provides precise costing at the sales stage of the project and then automatically creates the design drawings, explains Weaver. "Changing a vacuum pump configuration automatically updates the options and re-prices the system,” he says. “The software also enforced rules. It only allows selection of options suitable for use with the selected pump package. It won’t let you choose something incorrect."

Automatic drawing creation from the start

Not only can the software determine the cost of the selected base hardware and options, but the drawings can be created automatically, and it is simple once it’s set up. The limited options available allowed DuroVac to box in the configurations and design. It standardized the design of individual options, such as a differential pressure switch for filter level indication.

"The electrical relay logic design of the standard switch hookup and where its contact is used to shutdown the system in the start/stop circuit was created and controlled," notes Weaver. "This was done for all the options and made it easy to include or exclude options. Each electrical logic design also has a discrete bill of materials tied to it."

The end result is a configurable control cabinet. "DuroVac needed to find a supplier who could take these discrete pieces of relay logic and material lists and could price and build the panel," says Weaver. "A price was determined for the base system, with the vacuum pump, control enclosure with the start/stop buttons and the remote start/stop connections. And the options were added underneath. Every one of our configurable options have a cost, sell price, parts list and a discrete logic design tied to them. We know the exact cost, what to order and how to build and wire."

For DuroVac’s purposes, 80% of the time this works where things are always the same but different, notes Weaver. "Once that structure was in place, the drawings needed to be automated,” he says. “Instant pricing is fantastic, but the other aspect is that if the discrete logic is the same regardless of the size of the option, the discrete relay logic drawings for the option can be separated. A separate part number for each option is associated with a schematic drawing that can be added to the base schematic drawing. And the drawing has the bill of materials. The part number and drawing are linked."

With the configuration of the system defined during the sales process, the main drawing is then modified using layer control in AutoCAD and proprietary software that turns on and off the specific relays and wiring related to the option, explains Weaver. “The drawings are available instantly instead of waiting for them to be completed after the purchase order is received,” he says.

Applying the benefits

The configurable control cabinet system works well after the initial four-month development project. An attempt with another company took about 18 months and got nowhere, so DuroVac looked to expand its relationship with Eaton, explains Weaver. "We have been using Eaton to build our standardized panels for a number of years, and they have been very successful,” he says. Because of this, Weaver shared his wish list for a configurable control cabinet system with his local rep, who obtained Eaton's corporate support. DuroVac is now receiving the cabinets directly from Eaton's panel shop, which specializes in OEM projects and provides the UL-listed, NEMA 4 control enclosure, disconnect, circuit breakers, transformer, NEMA motor starters, solid state relays and terminals.

DuroVac and Eaton designed the motor starter control cabinet to be expandable for worst-case size and options using relays that are common for this and related OEM equipment. "We like the relays due to the cost benefit of relay logic, and there are only a few hardwired relay logic circuits needed," comments Weaver. "A single differential pressure switch and level switch doesn't lend itself to a PLC. The control cabinet is configurable with space in the cabinet to expand and support up to six relays and a timer."

Figure 3: Whether used for an outdoor central vacuum or a dust collection system, the benefits of the configurable control cabinet are the same.

Source: DuroVac Industrial Vacuums

The control cabinet can also support a motor starter for up to a 75-hp motor with two additional motor starters supporting up to 5-hp optional equipment. To assist panel layout and assembly, the back panel is predrilled for all configuration options with engineering fixed and pre-approved by Eaton.

Drawings comprise the specific control logic for the base devices and options. Each device is associated with a control part number, a control drawing, a BOM, a supplier part number, a supplier cost and a sell price. “We simply send a PO with a code, and Eaton knows how to build the panel," states Weaver.

Configuring with benefits

"The main benefits are speed and accuracy of costing and the benefit of having immediate drawings," notes Weaver. “This configurable panel is standardized across the pricing software. It's built in to the sales process. Quote the panel, and the design is done. This makes it supremely easy to configure and price our systems accurately. It allows us to shorten our shipping cycle by almost two weeks, which is a significant competitive advantage for us.”

Most of the benefits are realized in the panel-build stage, but the standardized nature of the design enables memorization of the wiring, speeding the integration and easing troubleshooting, says Weaver. “It really is a huge benefit to quickly and accurately quote something,” he says. "The system prices it and calls up the part numbers in a sales order, and you know they are correct. We associate the equipment options we select during a quote with a control option. The panel simply configures itself during a quote; we don't have to remember which control option to choose, and the drawings are automatically done."

The current automated drawing is proprietary to Northwind’s DuroVac brand of vacuums, but it could be developed for other customers (Figure 3). Weaver plans to introduce this configurable control cabinet system into the dust control industry, which also is the same but different. “It’s the same equipment, but different,” says Weaver. “We are in the process of putting this system on-line and it is going well.”

DuroVac needed to find a supplier who could take these discrete pieces of relay logic and material lists and could price and build the panel.