Autometrix creates industrial cutting systems that are known for precision, waste reduction and consistency. We build accurate, low-maintenance machines that can cut everything from textiles to composites.

Our next generation of industrial cutters needed to maintain high accuracy, while ensuring reliable intra-machine networking capabilities into the future. We needed precision when working with very expensive material, which requires heavy data communication between subsystems.

Autometrix needed to find a fast Ethernet switch that could withstand the vibrations normally found in this environment, while being extremely exact to provide the best networking capability possible. The best-case scenario was to avoid a costly redesign of the systems (Figure 1).

Figure 1: Autometrix needed to find a fast Ethernet switch that could withstand the vibrations normally found in this environment.

(Source: Autometrix)

A fast, smooth and precise history

In the late 1970s, John Palmer, founder of Autometrix, began developing software for automated industrial equipment. With a desire to create the highest-quality computer-controlled cutting machines possible, Autometrix was founded in the late 1980s. With experience developing software for cutting equipment, we developed a cutting machine that was faster, more reliable and more precise than any other machine of its time.

Over the years, the machines have gotten even better, all while maintaining the same reliability customers have come to count on. Throughout this time, the overall philosophy of the company has remained the same: Autometrix is dedicated to providing the best industrial software running the best cutting machines on the market.

Cut it out

Autometrix has developed PatternSmith—a software suite that complements its smooth and fast cutting equipment, which utilize precisely steered cutting tools on a CNC motion system to create high-quality parts from a wide range of materials. The machines are capable of carrying and using a wide range of cutting tools for nearly any flexible material. We provide a wide range of machine sizes, from the size of a dinner table to machines wider and longer than school buses.

An interface for cutting

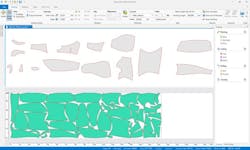

PatternSmith is a full-featured CAD tool for creating and modifying digital patterns (Figure 2). It uses a built-in interface that acts as the portal for connecting to a cutting machine. However, machine interface is just a small aspect of what it does.

Figure 2: Autometrix developed Patternsmith as a CAD tool to create and modify digital patterns for use on its cutting machines.

(Source: Autometrix)

There are a large number of supporting software suites available that enable pattern-drafting, editing, nesting and machine-control capabilities including Eclipse, Tailormade and CADShot. It's a very powerful tool for creating all kinds of products out of industrial textiles and other sheet goods (www.controldesign.com/patternsoftware).

Reliable communication

Autometrix’s motion control is fast and smooth, especially when it comes to complex shapes. Our machines utilize the latest materials to increase performance and maximize the lifespan of parts. To stay ahead of the competition, reliable industrial Ethernet communication is critical. To improve machine communication, Autometrix upgraded to Techaya’s MilTech 309, an eight-port, fast-Ethernet switch onboard (ESoB) for all of the systems it manufactures (Figure 3). The MilTech 309 was the best option to address the size, reliability and vibration concerns of an industrial environment.

The onboard electronics allow for minimized cabling and connect a number of peripheral subsystems on the machine that need fast and reliable communication. By developing a custom interface to mount the PCB-level MilTech 309, a high level of integration was achievable.

The MilTech 309 fast-Ethernet switch is a complete system-level board with eight 10/100 Mbps ports. With board-to-board connectors, it serves as a robust solution for providing local area network (LAN) connectivity to IP-enabled computing and netcentric systems. Developed to be embedded in small, harsh environments, the MilTech 309 is less than 1.7 x 3 x 0.5 inches and supports a wide temperature range.

Figure 3: An eight-port fast-Ethernet switch on board (ESoB) is attached to Autometrix's electronic control board, providing Ethernet communication to several peripheral subsystems.

(Source: Autometrix)

Control and machine secrets

Much of what makes Autometrix machines so fast and smooth is embedded in the proprietary design of our motion control systems and the associated firmware. The main obstacle to smooth motion for steered tool-cutting machines is breaking shapes up into segments that are then executed one after another. This creates choppy motion. Even when executed well, it results in hesitant motion. When executed poorly, it results in stops and pauses mid-pattern when cutting. In contrast to that, Autometrix and its partners have spent many years working to create a vastly different approach to motion profiles that eliminate a lot of that hesitation. Shapes can be executed much faster by removing a great deal of segmentation from the pattern execution.

In addition to the unique control system, carbon fiber is used as a central component of the machine to make the moving parts as light and strong as possible. Combining that with mechanical tolerances well in excess of industry standards leads to high cut precision and repeatability. All of this is ensured with direct quality control, as all machine hardware is designed and assembled at Autometrix’s northern California facility.

Nicely cut

Our machines’ electronics boast great serviceability and reliability by utilizing a compact and removable electronics cabinet. One of the things that contributes to that compactness and reliability is the Techaya Ethernet switch. It enables high-speed communication in a small package at the board level, and its military-grade vibration rating means that a machine’s integrated network will be reliable even in the harshest environments.

In a computer controlled industry, adding a reliable network to any machine is a huge boost in functionality, and the MilTech 309 allows Autometrix and its customers to add features, improve performance and stay on the cutting edge in a cutting industry.

The beauty of the Techaya product is that, aside from adding the interface, the integration is an overnight addition to a system, and issues associated with the integration are minimal.

Since implementing the MilTech 309 in the machines, we haven’t seen a single failure—not even a dropped data packet. The MilTech 309’s networking and density features gave the opportunity to develop new and more capable machine tools.

The great support received from MilSource, the exclusive distributor of Techaya products in the United States, makes it a worthwhile addition to any system.

ALSO READ: New technology pushes machine smarts to the edge

Leaders relevant to this article: