Manufacturers are increasingly relying on digital twins to improve design, commissioning and operational efficiency, but there are even more possibilities for the technology. In the course of achieving these objectives, digital twins are providing additional, unexpected collaboration benefits in the sales realm.

Founded in 1996, A.G. Stacker is a custom manufacturer, engineering line solutions and fabricating tailored industrial machinery for corrugated material stacking and handling operations. A.G. services a variety of end users, ranging from sheet plants to converting facilities, and from global multi-facility box makers to local family-owned converters—all of whom expect reliable operation and continuous innovation.

A.G. deployed Siemens’ digital-twin technology to enhance its design and manufacturing processes and to elevate the training experience for its end user’s equipment operators. As the company developed these digital twins, it quickly realized it could also use the modeling and simulation capabilities to improve upon the sales and purchasing experience for itself and its end user customers.

Machine builder and end user challenges

In the age of plug-and-play technology and intuitive apps among personal electronic devices, end users expect similar convenience for operating machines. This is increasing the pressure on original equipment manufacturers (OEMs), compounded with the always-present high cost of investment when developing new machines.

And the challenges are not limited to OEMs. Though end users do not carry the same risk of ensuring proper machine function, they consider ease of operation and staff training as key issues. In a traditional machine development and delivery process, training cannot occur until equipment is received in the final facility and is commissioned, many months after an order is placed even in the best cases.

In the early stages of training, the threat of improper machine operation is a serious concern, as users require time at the outset to get acquainted with new machinery. Without quality training, facility operations run the risk of injury, lost product, damaged machines, costly repairs and unplanned downtime.

A training tool and proof of concept, all-in-one

Recognizing these risks and concerns, A.G. set out to change the machine design and training landscape, and we recognized the impact we could make on the entire machine-buying journey from concept to implementation. Using a digital twin, engineers and end users can visualize mechanical, electrical and automation components of machines, using a combination of hardware- and software-in-the-loop (Figure 1).

Digital-twin technology helps to facilitate productive collaboration between OEMs and their end user customers and partners. At a project’s outset, electrical and mechanical engineers use design software—such as Siemens NX Mechatronic Concept Designer (NX MCD)—to prototype quickly. With built-in visualization tools, a mechanical engineer can define a basic simulation to show end users how the physical machine will work.

It is not uncommon for engineering teams to employ early simulation to find choke points in a proposed machine and to improve efficiency of the design process and ultimately the finished product, but the A.G. team quickly foresaw the value of this prototype as a sales tool. This early machine visualization provides potential end users with the opportunity to make better-informed decisions about exact machine specifications for their applications.

Once a favorable model is identified, an end user submits the order, and the machine builder can quickly pivot from the proof-of-concept model to ordering components, assembling machinery and writing code. When tuned throughout the design, deployment and operation phases of the project lifecycle, this model continuously provides insights to improve efficiency.

Results at a trade show

As a testament to the digital twin’s effectiveness as a sales tool, a trade-show attendee recently visited A.G.’s booth and requested a customized corrugated material-handling machine demonstration. The attendee communicated the machine requirements to A.G. That evening, A.G. staff put together a model with the attendee’s specifications, and the next day, A.G. demonstrated a working simulation of the desired machine.

The attendee was able to quickly verify the machine would provide what was needed, without the need for heavy machinery in the demonstration, simply computerized components running the digital twin and industrial automation software.

In a trade-show environment, setting up training stations saves time and money by eliminating the need to transport massive machines across the globe. And in the production world, the training-station methodology increases end-user learning opportunities and improves the speed at which new machines hit the market by reducing both learning and physical commissioning time.

Adjust to the environment

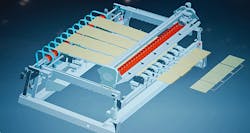

Figure 2: A.G.’s Digital Innovations Lab provides a space for learning, innovation, user feedback and machine optimization. (Source: A.G. Stacker and Siemens Digital Industries)

Running a simulation, stakeholders can determine how well a machine will accomplish its intended purposes before getting too deep into design and fabrication. Designers and developers can discover issues, adjust mechanical and electrical components, and tune automation logic in the early stages of development to prevent equipment bottlenecks and other problems down the road.

A.G. is innovating its entire scope of machines with Siemens digital-twin technology, beckoning in a digital future with automation components adapted to new technologies. We are equipping machines with the ability to learn and improve, optimizing production and helping meet rapidly evolving industrial manufacturing needs. These include quickly scaling, retaining labor, training clearly, and maintaining high-quality production.

Additionally, A.G. maintains and is expanding a Digital Innovations Lab at our headquarters, housing training stations for the machines (Figure 2).

The lab provides a space to learn how to operate A.G.’s machines, and it also serves as a center for research and development. Not only do A.G. end users test drive and learn machines here—producing valuable user insight and feedback—but A.G.’s employees also collaborate on designs cross-departmentally, devising plans for improving machines. The use of virtual reality in this setting provides the ideal environment to train personnel on both operating and building machines.

Digitalize the machine

Figure 3: The digital-twin ecosystem combines 3D modeling, PLC code and the HMI application in one simulation, demonstrating a machine’s capabilities with the flexibility of hardware- or software-in-the-loop. (Source: A.G. Stacker and Siemens Digital Industries)

Simulation vastly improves design, decision-making and machine efficiency, but ensuring an accurate model is essential for realizing these benefits. To create a machine’s digital twin, a designer begins with computer-aided design (CAD) software, such as Siemens NX MCD, to define application components. These include rigid bodes and collision bodies. Rigid bodies represent fixed machine components in the model, while dynamic collision bodies react according to the laws of physics in the simulation.

Next, the designer creates motion-control joints—sliding, hinged and other axes of interaction between two bodies—and actuators to control component speed and position. For a worthwhile simulation, just drafting machine motions is not enough. It must also showcase how the machine acts on products.

Products and other external objects can be added, with certain spawn and removal points in the simulated three-dimensional space. Additionally, Siemens NX MCD software and the TIA Portal integrated automation suite provide the capability to synchronize tags between the model and the automation project. This makes it easy to simulate the 3D model in lockstep with PLC logic (Figure 3).

A.G. currently uses S7-PLCSIM Advanced software as a virtual PLC, with standard PLC simulation logic driving the mechanical machine models. This enables observation of machine movements in the CAD-based modeling environment, as well as the ability to visualize and control the machine using the real HMI application and hardware. The HMI can also be simulated with a PC application, if preferred.

Figure 4: Though the CAD model and PLC are virtual, A.G. Stacker end users learn the application using the actual touchscreen HMI model equipped on the real machine. (Source: A.G. Stacker and Siemens Digital Industries)

The Siemens suite of simulation and modeling software turned A.G.’s vision of an improved sales-and-marketing tool into a reality. The timeline to progress from initial end user interest to a new fully functional corrugated material-handling machine traditionally takes years. But the reduced time and cost investment required to create a simulated proof of concept and the design flaws it helps to detect and prevent when building the real machine cuts the process down to between 12 and 18 months in most cases.

Additionally, training can begin as soon as the digital twin is ready. Technicians no longer must wait for machine building, shipping and commissioning before they begin learning how a machine operates.

A.G.’s end users are now visualizing and learning how to operate their custom machines in the simulation environment just a few months into the machine-building phase. Operators interact with software-in-the-loop using the actual HMI hardware of a real machine, providing a realistic environment for learning to control the machine effectively (Figure 4).

Figure 5: A.G.’s eBreak training station utilizes the real machine’s HMI panel to prepare users to operate the machine long before it arrives at the facility. (Source: A.G. Stacker and Siemens Digital Industries)

Additionally, learning in a simulated environment improves safety and reduces cost risks, as operational errors do not result in accidents, wasted product or machine downtime. Staff can dial in ideal machine parameters in the simulated environment, and, once the real equipment arrives, they can start producing promptly because they already know how to operate it.

Companies are increasingly creating and utilizing digital twins on segments of machines, but digitalizing an entire machine is often viewed as too complex an endeavor. However, A.G. is proving the benefits far outweigh the cost.

When digital twin methodology is applied to segments, the goal may be to reduce design risks for more complicated elements, or sometimes to serve as a visual gimmick. But A.G. is not in it for the show, and a carefully crafted and accurate digital twin makes the machine products more efficient and easier for users to understand. It streamlines machine design and fabrication, and it increases operational efficiency. This benefits end users throughout their entire equipment lifecycles, creates the opportunity for better OEM support models and ultimately results in machines producing higher quality and quantity of products.

Machine examples

In coordination with our end user customers, A.G. kickstarted the digital journey by creating digital twins for three of our common machines: eBreak bundle breaker; Divert and Separate System (DSS); and eTamp.

The eBreak digital-twin training station makes it easy to establish and recognize corrugated material break points. The simulation functions just like the real machine, providing the opportunity for operators to become familiar with operational procedures and different types of possible breaks such as straight and nested. The station utilizes Siemens PLCSIM Advanced, NX MCD and WinCC Unified HMI software, along with a WinCC Comfort HMI panel (Figure 5).

A.G.’s DSS implements recipe creation and management for many product order types. The DSS varies mechanical arm spacing based on the dimensions of corrugated material being separated, and the recipes make it easy to store and recall proper spacing for each particular product type. This eliminates the need for operators to manually adjust spacing, reducing complicated setup and idle time. Similar to the eBreak training station, the DSS digital twin is also a mechanism for training, so technicians can learn how to use the machine with real hardware prior to fabrication and delivery (Figure 6).

The eTamp machine provides automatic tamper adjustment for sorting and stacking corrugated products. The digital-twin training station runs simulated PLC code with a real HMI interface to provide a means for operators to learn how to position motion axes and run product without fear of jamming a real machine. Should a jam occur in the simulation, the user can quickly clear material and begin training again with a clean slate, helping to familiarize and provide operator confidence (Figure 7).

Figure 6: A.G.’s DSS uses the recipe manager to store product-specific separation arm positions and other parameters for quick and accurate recall. (Source: A.G. Stacker and Siemens Digital Industries)

For actuators, A.G. uses electrical components to eliminate hydraulic and pneumatic points of failure, simultaneously speeding up the machine-building process and eliminating complex hydraulic and pneumatic knowledge requirements for end users. Linked up with the digital twin, these smart actuators provide diagnostic feedback, easing troubleshooting and providing A.G. with the ability to remotely adjust electronic devices.

Because electrically, hydraulically and pneumatically trained maintenance personnel are hard to come by, advanced capabilities for remote support with a digital twin help to reduce a machine builder’s risk and an end user’s downtime. The presence of electrical—and absence of hydraulic and pneumatic—components results in a more convenient and environmentally friendly support model for A.G. and its end users, yielding quicker issue responses and reduced requirements for travel.

Figure 7: Training with a digital twin in the software environments is a safe means for learning because jams and other issues can be cleared with the press of a button. (Source: A.G. Stacker and Siemens Digital Industries)

A.G. also benefits from enhanced machine and market business process feedback, so we better understand user needs. This enables A.G. to innovate and adapt more quickly with versatile machines, and it simultaneously builds trust among existing and potential new end users.

Digital twin and beyond

A.G. Stacker’s partnership with Siemens showcases five primary benefits of using digital twins:

- Mechanical design validation—the ability to see how a machine will work prior to its physical creation.

- Virtual commissioning—the ability to tie in models and factory automation tools, bridging the mechanical and automation worlds.

- Virtual training—easing the training process for machine builders and enhancing operational capabilities and know-how for end users.

- Prototyping—machine builder’s sales tool, enabling potential buyers to try before they buy.

- Support and service—the ability to provide users a proof of concept for new materials and products before they commit to ensure their requirements can be met by the machine. This eases new setup and reduces material waste and downtime, increasing speed to market.

End users on the digital journey are looking for progressive machine-builder partners who understand digitalization technologies and are incorporating them in their own internal processes. A.G. no longer builds machines without creating the accompanying digital twin first, before machine fabrication even begins.

On the horizon, A.G. Stacker is planning to branch out beyond using digital twins for just individual machines and move into entire integrated facility simulation. We are on the road to becoming a digital enterprise, adept at uniting enhanced business processes, technological innovation and heightened human involvement.