EinDollarBrille uses 3D CAD software to replicate affordable-eyewear-manufacturing machines worldwide

Poor vision restricts many people, especially those in impoverished areas, from learning and working. According to the World Health Organization 2019 global study on vision, approximately 2.2 billion people have vision impairment or blindness, and almost 1 billion of the cases could be prevented. But many people cannot afford eyeglasses or do not have an optician near them.

When this global problem came to the attention of Martin Aufmuth, a math and physics teacher in Erlangen, Germany, he decided to put his expertise in physics, specifically optical lenses, as well as his knowledge of the human eye’s characteristics, to use and do something to help these people.

His efforts became EinDollarBrille, which literally translates to $1 eyeglasses, the price point Aufmuth’s organization strives to stay below to keep its eyewear affordable.Founded more than 10 years ago by Aufmuth, who is also the CEO, EinDollarBrille now provides tools and training to enable its team and partners across 10 countries to manufacture these glasses using equipment that requires no power supply (Figure 1). The revolutionary machine won first prize in the 2013 Siemens Stiftung empowering people Network (epN) Awards. Further development and manufacturing are being accomplished using Solid Edge software from the Siemens Xcelerator portfolio.

“I wanted to create eyeglasses for less than a dollar's worth of materials, so that even the poorest could afford them,” says Aufmuth, who’s managed to maintain the cost of the glasses at less than $1. “To really offer long-term and sustainable help we didn’t want to simply ship out glasses, but rather enable the people in the respective countries to help themselves. That’s why our plan was to get the OneDollarGlasses designed and manufactured on-site with a machine that didn’t require electricity.”

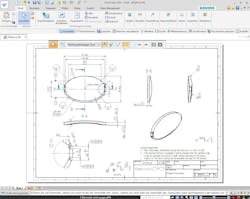

After developing his initial concepts, prototypes and sketches using mainly manual and non-digital methods, Aufmuth realized manufacturing processes needed to be set up to achieve production—a process that starts with design, drafting and digitalization. While there were individual sketches and drawings of the wire-frame bending machine, there were no 3D CAD models that could be used for the next steps—for example, providing data that could be transferred to computerized-numerical-control (CNC) manufacturers to aid in the machine build.

To solve this, Siemens’ Solid Edge and one of Siemens’ solution partners, PBU CAD-Systeme, began working together in early 2022. With the help of CAD consultant and volunteer Sabine Adams, the bending machine, now on its 13th generation, was developed further and perfected while other tools and gauges required for glasses production have been optimized (Figure 2).

For the bending machine, Adams received the existing hand sketches and some technical drawings on paper with handwritten notes. Together with the team, she defined the dimensions and tolerances, as well as the necessary forms to get the bending machine professionally defined and documented.

Since the invention of the OneDollarGlasses machine, the organization has grown to encompass around 500 volunteers and employees worldwide. The project has spread throughout Africa to countries such as Kenya, Malawi, Burkina Faso and Liberia. In Latin America, OneDollarGlasses can be found in Brazil, Colombia, Peru and Bolivia. The non-governmental organization (NGO) is also successful in India. Since the start of the program in 2017, around 75,000 people have been provided with glasses. Globally, the aim is to establish basic optical care in close cooperation with local partners, other organizations and government institutions to address the problem of defective vision. Siemens’ Foundation is one of the partners.

On the bending machine, glasses can be produced in different sizes: the yellow marking is for small glasses, the red for medium glasses and the blue one for people with a large eye relief. Colorful beads are added to give the glasses a pretty design. The pre-ground plastic glasses are unbreakable and scratch-resistant. The basic range consists of different strengths from -10.0 to +8.0 diopters, and the glasses can be clicked into the frame with a single movement.

OneDollarGlasses finances the training costs, bending machines and project construction from donations. Part of the costs are already covered by the sale of the glasses.

About the Author

Mike Bacidore

Editor in Chief

Mike Bacidore is chief editor of Control Design and has been an integral part of the Endeavor Business Media editorial team since 2007. Previously, he was editorial director at Hughes Communications and a portfolio manager of the human resources and labor law areas at Wolters Kluwer. Bacidore holds a BA from the University of Illinois and an MBA from Lake Forest Graduate School of Management. He is an award-winning columnist, earning multiple regional and national awards from the American Society of Business Publication Editors. He may be reached at [email protected]

Leaders relevant to this article: