- Why are operator buttons needed if an HMI can provide the same function?

- What are some of the best ways to indicate alarms and confirm that appropriate operator action has occurred?

- How can stack lights improve machine or system productivity?

- How do I indicate and describe alarms without overloading an operator with too much information?

Why are we still using stack lights, annunciators and push buttons? Are machine designers going for a retro look with these antiquated analog components? Or maybe it’s the hipster in them, wanting to show that they were building machines with interface devices before interface was cool. “That annunciator sounded way better on vinyl.”

Human-machine interface (HMI) can offer a digital version of almost any button, knob or light, but analog still has its place on machines, whether it’s for its ruggedness, for no-look interaction or for situations in which touchscreen operation isn’t an option.

We posed several questions regarding these time-tested components to a panel of industry veterans to see what light their experience and expertise might shed on the subject.

How are end users implementing stack lights on multi-station assembly lines?

Will Healy III is marketing management director at Balluff.

Just like on a small machine, operators on long assembly lines can see the equipment status in their areas of responsibility in real time via an indicator light. This may include visual feedback for normal running operation, warning, or fault conditions—green, yellow, red, respectively. They can sometimes actuate blue or white stack light color segments to get the attention of supervisors, maintenance or raw-material fulfillment personnel.

Stack lights along a longer assembly line allow the operators at each machine segment to follow work flow upstream and downstream. This can let them know if they are holding rate—keeping pace—if a work cell upstream may be down for a bit or if a station downstream is backed up. This visual feedback can initiate resource management by a supervisor to add an operator or lead-hand to deal with a condition or bottleneck. It may lead to a maintenance call. Supervisors, lead-hands and other personnel responsible to keeping operators on task can be anywhere up and down the assembly line. Well-placed stack lights, in line of sight to normal work areas, can capture support personnel’s attention quickly and from a distance.

The specific details of a down situation may or may not be communicated by a stack light. Typically, that data is conveyed with pilot lights or at the HMI level. However, those devices require that the operator be at the control panel. On a long assembly line, the stack light may provide less data than other devices; however, its impact is immediate with a wide coverage area. The addition of a buzzer adds an audible element to capturing the attention of plant personnel.

Lee Clore is owner/controls designer at Onyx Industries.

Robb Weidemann is senior business development manager at Banner Engineering.

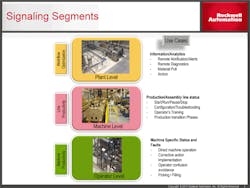

Figure 1: Signaling has many different uses impacts on productivity.

(Source: Rockwell Automation)

Alvaro Sanchez is product manager at Rockwell Automation.

Sopan Khurana is applications engineer at Patlite.

Stack lights are simple to implement and provide quick status indication for a machine. Red indication might identify a machine stoppage of some sort requiring user intervention. Green typically indicates normal operation. Stack lights are also used to identify other information—for example, the raw-material hopper’s getting low and needing to be replenished could be indicated by a flashing blue.

All in all, discrete manufacturers with multi-station assembly lines like the simple indication a stack light provides, and there are no signs of this technology being replaced anytime soon, only innovated more.

Michael Day is industrial control products market development manager at Siemens.

Michael O’Neill is president at Werma-USA.

Zach Tinkler is U.S. product manager, control and signaling at Schneider Electric.

ALSO READ: Harsh environments call for more rugged components

Mike Bacidore is the editor in chief for Control Design magazine. He is an award-winning columnist, earning a Gold Regional Award and a Silver National Award from the American Society of Business Publication Editors. Email him at [email protected].

About the Author

Mike Bacidore

Editor in Chief

Mike Bacidore is chief editor of Control Design and has been an integral part of the Endeavor Business Media editorial team since 2007. Previously, he was editorial director at Hughes Communications and a portfolio manager of the human resources and labor law areas at Wolters Kluwer. Bacidore holds a BA from the University of Illinois and an MBA from Lake Forest Graduate School of Management. He is an award-winning columnist, earning multiple regional and national awards from the American Society of Business Publication Editors. He may be reached at [email protected]

Leaders relevant to this article: