How are you getting your share of the pie that is the $227 quadrillion Industrial Internet of Things (IIoT)? That’s a lot of money, and there’s plenty to go around, so what are you doing to cash in on this next industrial revolution? OK, to be fair, I made up that number. But, unless you’re a research analyst or someone putting together Q3 forecasts for your business unit, you didn’t even give that number a second thought.

And you probably shouldn’t. It doesn’t really matter. That number is as justifiable as it is arbitrary. Just pick an amount and then create a scenario and a timetable you can defend. “If you torture data long enough, it will confess,” Ronald Coase once said. The famed British economist also believed that the study of real-world markets was much preferred to speculating on theoretical ones.

In reality, this bold new landscape of connectivity has yielded opportunities for revenue streams steered by embankments of innovation. Nowhere was that more evident than at Hannover Messe in Germany, where Industry 4.0—the preferred European term, which includes IIoT, cyberphysical systems and more—was impossible to avoid and insistent in its resolve.

What’s the benefit?

Connected machinery gives the users and the builders and the component manufacturers and the cloud software companies the ability to monitor equipment health and conduct predictive analytics on the data. This means increased machine reliability by performing scheduled maintenance based on conditions and avoiding downtime because of equipment failure. Equipment failure can be extremely costly, and reducing or eliminating it is low-hanging fruit that the IIoT will allow organizations to pluck immediately. Predictive maintenance has been around for decades, but it’s a concept whose time is long overdue. And cloud connectivity will flatten enterprise networks and will harmonize IT and OT data.

But reduced maintenance costs are just a taste of the bounty to come. While equipment reliability will surely benefit, productivity and efficiency gains are where the real payoff lies. The ability to modify engineering capacity based on real-time data will translate into increased profits, affecting every aspect of the enterprise from a streamlined supply chain to customized product offerings.

“Time to market is one of the biggest issues in the world today,” said Raj Batra, president of Digital Factory for Siemens USA, one of the many bright minds speaking in Hannover. “It's about getting to market fast. Historically, the IT organization was very decentralized. There wasn't technology that spanned the spectrum. You can't control your manufacturing costs if you don't control your design.”

Imagination and innovation will run wild with the tools and automation that are literally at our fingertips. If this is starting to sound like futuristic science fiction, well, you’re half right. The technology is here. It’s real and it’s available. But how do we implement it when capital equipment typically won’t be replaced until the end of its useful life?

German technology company Harting won the 2016 Hermes Award at Hannover Messe for its Modular Industry Computing Architecture (MICA) product, an open, modular platform consisting of embedded hardware and software that allows intelligence to be added to existing machines and equipment to enable Industry 4.0. Through Linux technologies, MICA lets users virtualize field devices and add customizable hardware components that communicate via USB, and it can be operated using Power over Ethernet (PoE). Each unit contains a TPM chip and supports both SSL and VPN to allow secure authentication and communication between MICA modules.

Chaired by Dr. Wolfgang Wahlster, director of the German Research Center for Artificial Intelligence (DFKI), the Hermes Award jury was impressed by the concept of lightweight virtualization using Linux-based containers which MICA implements on compact field devices. “By installing numerous integrated MICA modules, which essentially represent the nervous system of a digitized factory, an existing plant can be gradually migrated over to Industry 4.0, shortening the time needed for product changeovers along the way,” said Wahlster.

Figure 1: The 13th annual Hermes Award for outstanding products, innovations and solutions displayed for the first time at Hannover Messe 2016 was awarded to Germany’s Harting. Dr. Karsten Walther (left), Harting IT Software Development, and Philip Harting (right), CEO, Board Connectivity & Networks, Harting Technology Group, received the award from Prof. Dr. Johanna Wanka, German Federal Minster of Education and Research, at the event’s opening ceremony.

“Since 1947, Harting has been an exhibitor at Hannover Messe and over the intervening decades has evolved from being a pure hardware manufacturer to becoming a software-driven technology provider,” said Dr. Jochen Köckler, member of the Deutsche Messe Managing Board. “The award-winning MICA product represents a key contribution to the keynote theme for this year’s Hannover Messe and will make it easier for small and medium-sized enterprises to enter the world of Industry 4.0.”

The award was presented by Prof. Dr. Johanna Wanka, German Federal Minister of Education and Research, to Dr. Karsten Walther, Harting IT Software Development, and Philip Harting, CEO, Board Connectivity & Networks, Harting Technology Group, at the Hannover Messe Opening Ceremony on April 24, which was attended by U.S. President Barack Obama and German Chancellor Angela Merkel (Figure 1).

Other companies nominated for the Hermes Award were Block Transformatoren-Elektronik, also of Germany; DDM Systems from Atlanta, Georgia; ITM Power of the United Kingdom; and J. Schmalz of Germany.

Financing the revolution

The Fourth Industrial Revolution will require companies to invest around the world, and a new study shows the role of financing is rising, particularly among small and mid-sized enterprises. This will result in investments of 250 billion euros by 2025 in Germany alone, according to research conducted by Boston Consulting Group. For the United States, this figure will amount to about $300 billion over the next three years. Manufacturers consider financing to be one of the five critical success factors in business, according to a global survey of CFOs at manufacturing companies that Siemens Financial Services (SFS) shared during a roundtable at the Hannover Messe 2016.

The other success factors are use of the latest technologies, increased operational efficiency, expanded product capacities and flexibility, as well as more competitive price structures. Respondents also said they needed simple, flexible, reliable and sustainable financing, provided by a partner that understands the industry.

“The Fourth Industrial Revolution is primarily about continuous, not one-time, investment, about being able to always use the newest technology rather than having to make a one-time purchase,” said Roland Chalons-Browne, CEO of SFS.

Digitalization is all about future payment streams and earnings potential. "Digitalization means huge opportunity for manufacturing,” said Siemens’ Batra.

“Digitalization is digitizing your assets to get value out of them,” explained Del Costy, vice president, U.S. country manager, Siemens PLM Software. “Determine where you want to take that. If you're dealing with complex manufacturing problems, digitalization lets you create the digital twin and simulate the manufacturing floor.”

During the roundtable, SFS discussed a number of financing solutions that facilitate long-range investments including pay-per-use models and “finetrading,” which is used to finance purchases of goods and enable companies to make flexible payments within a period of up to 180 days.

“The trend is moving in the direction of more flexible financing models, and this is just what we provide,” explained Chalons-Browne. “Through our combination of technology and financing knowledge, we can better assess risks as well as opportunities and develop tailored solutions. The Fourth Industrial Revolution is creating tremendous growth potential for small and mid-sized enterprises. Our financing solutions enable these companies to tap it."

Software takeover

“The role of software is increasing,” explained Wolfgang Portugaller, head of system architects, B&R Industrial Automation. “Many machines have been in operation on the shop floor for 20-25 years. Those machines have to be maintained. Reducing the maintenance effort is key for the machine builder to reduce total engineering costs and increase its profitability.”

How can you reduce the maintenance effort? “This is where the software engineer raises his hand,” offered Portugaller. “Modularity of the whole system is the key. Modular systems can be maintained, and separation of concerns is one way to make a machine more modular. This means a lower maintenance effort.”

At Hannover Messe, B&R introduced its cooperation with Canadian system integrator ATS Automation to market solutions integrating ATS’ industrial transport technologies with B&R’s control architecture to create new capabilities designed to go beyond conventional linear-motor-based conveyances.

The limitations of conventional conveying systems—speed and precision—as well as maintenance difficulties, such as belt tightening, are addressed by B&R’s next generation of industrial transport technology. Variable-speed conveying means no need for acceleration and deceleration conveyors. It’s also designed for production efficiency at any batch size. Faster product format changeover without mechanical adjustments translates to smaller, profitable production runs with a reduced machine footprint and line-rate increases of 50%.

ATS Automation’s 14 years of linear-motor-based transport technology is complemented by B&R’s software and robotics/CNC integration, which provides the interface to the automation systems with mapp technology and Automation Studio.

Synchronization, sequencing and integration with CNC, robotic, sensing and actuation are critical in manufacturing strategy. The machine’s automation can synchronize robotic operations with pallets that are in motion, move pallets forward and backward to perform multiple operations and optimize sequencing to minimize wait times between stations.

Simulation can be used to model the system and optimize cycle rates in advance. Work stations are infinitely adjustable across the entire track, so accumulation space is virtually eliminated. Wear parts are reduced to shuttle wheels and the tracks they run on.

With this machine, B&R has extended its mapp-technology approach to industrial transport, in which connected mapp objects with the familiar attributes of IEC function blocks allow the machine builder and user to program less and configure more.

Equally important to the integrated approach is B&R’s one-wire, one-program, one-processor, one-software development environment for all aspects of the system—robotics, general motion, CNC, logic, Web-based HMI, networked safety, vision, sensors, actuators, adhesive applicators, printers, light curtains and feedback devices. This is enabled through Automation Studio and over the PowerLink industrial Ethernet network.

Global PC control

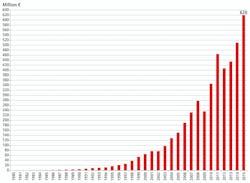

Beckhoff Automation announced global annual revenue of 620 million euros in 2015, an increase of 22%, following a 17% increase the previous year (Figure 2). “We won market share and grew much faster compared to the market as a whole,” said Hans Beckhoff, owner and managing director. “Our PC Control technology is increasingly the acknowledged market standard, and we are winning new customers worldwide with this extremely powerful technology.”

Figure 2: At Hannover Messe, Beckhoff Automation announced global annual revenue of 620 million euros in 2015, an increase of 22%.

Beckhoff explained that the favorable euro exchange rate naturally helped increase growth, as with all German manufacturers who export a large share of what they make. Represented in more than 75 countries, Beckhoff exports accounted for 65% of sales. “Asia is contributing strongly to our growth,” said Beckhoff. “However, subsidiaries in southern Europe and North America are also performing quite well.”

To prepare for continued growth, the campus at the company headquarters in Verl will be expanded by 27,000 square meters. “This appropriately prepares us for two further years of strong growth in terms of production output,” said Beckhoff. “We will again invest heavily in research and development in 2016, allocating funds of roughly 45 million euros. Technology is our business, but it is also a source of joy for us.”

As Industry 4.0 becomes a reality, Beckhoff plans to be on the leading edge of the technology (Figure 3). “Ideas are being transformed into real products that enable machinery to be used far more productively, manufacturing more goods in higher quality,” stated Beckhoff, whose company currently employs about 3,000 individuals globally, most of which work in Germany at the global headquarters.

Figure 3: As Industry 4.0 becomes a reality, Hans Beckhoff, owner and managing director of Beckhoff Automation, sees ideas being transformed into real products that enable machinery to be used far more productively, manufacturing more goods in higher quality.

Figure 4: At Hannover Messe, Beckhoff presented new IoT products, demonstrating connection of automation and field levels with the Microsoft Azure cloud.

Trained engineers account for one-third of the workforce. “Our unwavering commitment to develop junior staff and apprentices focused on industrial and academic disciplines is resulting in considerable success,” said Beckhoff. An on-site master’s course will be offered in the future at the Gütersloh branch of Germany’s Bielefeld University of Applied Sciences in addition to the current bachelor’s degree course.

To the cloud

As a partner at Microsoft’s Hannover Messe booth, Beckhoff also presented new IoT products, demonstrating connection of automation and field levels with the Azure cloud (Figure 4). The new EK9160 IoT bus coupler connects EtherCAT I/Os with the Microsoft Azure cloud directly and without the need for a specific control program. The coupler enables standardized integration of I/O data with cloud-based communication and data services.

To demonstrate the fast integration of industrial processes with the Azure cloud, Beckhoff presented a connected demo linked with a pick-and-place robot in the Microsoft booth. Process variables, such as energy or condition monitoring data for example, are stored and analyzed in the Azure cloud; through predictive maintenance, the availability of monitored systems can be increased.

The TwinCAT IoT software package contains various products for implementing MQTT and AMQP functionalities directly through the controller by means of function modules. Furthermore, the TwinCAT IoT Data Agent represents a gateway application that not only transmits data from TwinCAT 3 controllers, but also process data from TwinCAT 2 systems, as well as from third-party provider systems via OPC UA to Microsoft Azure communication services.

Beckhoff also presented its industrial automation controller with Windows 10 IoT Core Pro, the CX51xx Embedded PC, at the Microsoft booth. The controller captures the energy data of a consumer and supplies the process data to the Azure cloud by means of standardized communication.

Obama visits Phoenix

U.S. President Barack Obama and German Chancellor Angela Merkel spent the first morning of Hannover Messe visiting with exhibitors and experiencing the technology being displayed. One of the companies visited by the government officials and their entourage was Phoenix Contact, where Frank Stuehrenberg, Phoenix Contact CEO, and Jack Nehlig, president of Phoenix Contact USA, met with them (Figure 5).

Stuehrenberg and Nehlig demonstrated one of Phoenix Contact’s technologies, a fast-charging plug for electric vehicles for the European and American markets, known as the CCSplus, which is a new cable that can charge at up to 350 A, enabling a vehicle to charge in about five minutes.

Obama is the first sitting U.S. president ever to attend Hannover Messe, which highlighted U.S. companies as the partner country this year. Phoenix Contact is a German manufacturer with U.S. headquarters in Middletown, Pennsylvania. Since establishing an American subsidiary in 1981, the company has grown to employ 700 people in the United States, including 500 at its Middletown location, which boasts 100,000 sq ft of manufacturing space.

“We are honored that President Obama and Chancellor Merkel took the time to visit our company during their Hannover Messe tour,” said Nehlig. “Phoenix Contact USA is an outstanding example of the SelectUSA initiative and how German investment in the U.S. market can benefit both countries.”

Figure 5: Frank Stuehrenberg, Phoenix Contact CEO, (left) and Jack Nehlig, president of Phoenix Contact USA (far right) meet with U.S. President Barack Obama and German Chancellor Angela Merkel at the Hannover Messe in Germany.

German-American connections

The Lapp Group also received a visit from President Obama and Chancellor Merkel at the company's 2016 Hannover Messe booth, where the U.S. and German leaders learned about the latest technology innovations from Lapp, which is a German family-owned wire and cable manufacturer with its U.S. headquarters in Florham Park, New Jersey.

One of the major highlights at the booth was a basketball-playing robot made by Lapp’s customer Comau, which incorporates Lapp’s own ÖLFlex Robot cables. “The ÖLFlex Robot cables, which are laid inside the robot arm, must withstand quick and precise movement under high torsion, tight bending radii and severe acceleration,” explained Andreas Lapp, chairman. “Over a robot’s service life, this means that cables will be twisted 15 million times over 1,400° along their own axes. Typically, a cable cannot possibly withstand that kind of punishment, but our engineers made it possible. This way, Comau can give a full eight years of warranty on their robots.”

Lapp also presented Obama and Merkel with a set of data and power cables for robots. The escalation of the IoT means that robots and other machines increasingly need to be networked. The resulting rising data volumes and challenging mechanical requirements are extremely challenging for the cables.

Lapp’s EtherLine Torsion Cat.6A, for example, is designed to transmit up to 10 Gigabits of data per second even under permanent twisting. “I am impressed at how a family-owned business like Lapp has found international success,” said Markel.

The integration starts now

GE announced its complete Asset Performance Management (APM) solutions suite at Hannover Messe. Based on the Predix platform, APM is designed to bring comprehensive insight into production efficiencies and allow industrial companies to use data and cloud-based analytics to improve the reliability and availability of their assets, minimize total cost of ownership and reduce operational risks for both GE and non-GE assets.

While APM is not a new concept, companies have previously integrated disparate solutions to monitor and maintain their industrial equipment. No comprehensive solution has existed to support industrial data generated by these assets. For example, enterprise asset management (EAM) and enterprise resource planning (ERP) systems can report on how equipment was used and maintained, but they aren’t designed to analyze data that can be processed with big-data techniques to predict and prevent equipment issues.

APM powered by Predix combines GE’s expertise in both asset physics and industrial software to offer a cloud-based solution. Predix provides security, real-time data management and cloud infrastructure management. “GE’s deep expertise in developing and servicing machines for industry gives us a greater understanding of real business operations and the insights to deliver on industry needs,” said Derek Porter, general manager for Predix Applications, GE Digital. “With the launch of our APM solutions suite, GE is commercializing its own best practices for customers.”

GE also highlighted the first generally available module of GE Digital Brilliant Manufacturing Software Suite, Efficiency Analyzer. With manufacturers looking to take advantage of data, Efficiency Analyzer was developed to address the eroding time buffer between market demand and production. The module provides machine and production efficiency analytics to help reduce equipment downtime and scrap maintenance costs through improved visibility into operations, identifying bottlenecks and increasing yield.

With Efficiency Analyzer, GE is employing a new deployment approach through a software-as-a-service (SaaS) pricing model and minimal ongoing IT impact.

GE also uses these software products in its own plants. “GE’s Brilliant Manufacturing Suite has enabled significant reduction in unplanned machine downtime resulting in higher plant efficiency,” said Bryce Poland, Advanced Manufacturing Brilliant Factory Leader, GE Transportation. “As part of our digital thread strategy, we will increase our machines and materials visibility by 400% in 2016.”