The face of change: Meanwhile in the United States

From the United States, we awaited the arrival of the coronavirus with great trepidation, watching as countries overseas battled what would eventually become a global pandemic. Manufacturers raced to postpone normal operations, keeping workers safe and distanced, but many jumped at the opportunity to produce much-needed equipment and personal protective equipment (PPE).

[javascriptSnippet ]

Meanwhile in the United States

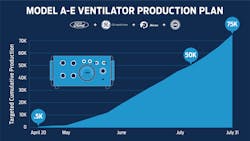

In collaboration with GE Healthcare, Ford leveraged the design of Airon’s FDA-cleared ventilator for production in Michigan. With the full weight of the UAW behind the venture and the full power of Ford and GE Healthcare, production of the GE/Airon Model A-E ventilator started the week of April 20 at Ford’s Rawsonville Components Plant in Ypsilanti, Michigan.

Ford expects to produce 50,000 of the ventilators within 100 days, with the ability to produce 30,000 a month thereafter, as needed.

Ford expects to produce 50,000 of the ventilators within 100 days, with the ability to produce 30,000 a month thereafter, as needed.

Ford will provide its manufacturing capabilities to quickly scale production, and GE Healthcare will provide its clinical expertise and will license the current ventilator design from Airon, a small, privately held company specializing in high-tech pneumatic life support products. GE Healthcare brought the Airon design to Ford’s attention as part of the companies’ efforts to scale production of ventilators quickly to help clinicians treat COVID-19 patients.

The GE/Airon Model A-E ventilator uses a design that operates on air pressure without the need for electricity, addressing the needs of most COVID-19 patients. Its production can be quickly scaled to help meet growing demand in the United States.

“The Ford and GE Healthcare teams, working creatively and tirelessly, have found a way to produce this vitally needed ventilator quickly and in meaningful numbers,” says Jim Hackett, Ford president and CEO. “By producing this ventilator in Michigan, in strong partnership with the UAW, we can help healthcare workers save lives, and that’s our No. 1 priority.”

Ford initially sent a team to work with Airon to boost production in Florida and start production at its Michigan plant. Ford expects to produce 12,000 by the end of May and 50,000 by July 4.

Ford’s plant will produce the ventilators nearly around the clock, with 500 paid volunteer UAW-represented employees working on three shifts. Airon currently produces three Airon pNeuton Model A ventilators per day in Melbourne, Florida. At full production, Ford plans to make 7,200 Airon-licensed Model A-E ventilators per week.

In part 4 of this series of articles, we dive into the transformation companies are going through amid adversity.

Mike Bacidore is the editor in chief for Control Design magazine. He is an award-winning columnist, earning a Gold Regional Award and a Silver National Award from the American Society of Business Publication Editors. Email him at [email protected].

About the Author

Mike Bacidore

Editor in Chief

Mike Bacidore is chief editor of Control Design and has been an integral part of the Endeavor Business Media editorial team since 2007. Previously, he was editorial director at Hughes Communications and a portfolio manager of the human resources and labor law areas at Wolters Kluwer. Bacidore holds a BA from the University of Illinois and an MBA from Lake Forest Graduate School of Management. He is an award-winning columnist, earning multiple regional and national awards from the American Society of Business Publication Editors. He may be reached at [email protected]