See the Future of Machine Vision

Applications that require speed, high resolution and good sensitivity to light will push vision-system technology forward.

John Butler, North American sales manager at Pleora Technologies (www.pleora.com), identifies those applications as:

Sorting systems—The faster the systems are the more cost-effective they can be; they are looking into 10 GigE in the near future.

Semiconductor manufacturing inspection—Companies get cutting-edge speed by using short wavelength imaging. Even though most companies are enduring the downturn, they can benefit from a 10 GigE throughput.

High-end surveillance and the military—Though not typical machine-vision systems, the military uses machine-vision technology and looks for nothing less than the latest advances, believes Butler.

“One trend has been toward more sensor-like vision systems that don’t require a computer for setup or programming,” says Brent Evanger, applications engineer, vision, Banner Engineering (www.bannerengineering.com/ivu). “A wide range of industries can benefit from the capable simplicity of a sensor that retains many of the features from higher-end, more-complex platforms while offering a comfortable, intuitive, digital-camera-like interface.”

Pharmaceutical and food and beverage applications for machine vision are expanding greatly, says Bradley Weber, director of application engineering at PPT Vision (www.pptvision.com). “For a relatively small cost, a smart camera ensures the quality, safety and traceability of the products being packaged,” he says. “The true advancements in machine-vision technology today are demonstrated in the software now available, which includes complex algorithms presented in an intuitive, easy-to-use way.”

A couple of industries that recently have benefited are the packaging industry and the solar industry, says Joshua Jelonek, technical product manager—vision and marking technology, Keyence of America (www.keyence.com).“One application would be inspecting for packaged goods through cellophane,” he states. “Previously it was difficult to get an accurate count on the targets, but by using some new image-enhancement tools we’re able to eliminate the glare from the cellophane to clearly see the product underneath.”

Any industry where fast, precise or repetitive measurements or readings are required can benefit from machine vision, says Ben Dawson, director of strategic development, Dalsa (www.dalsa.com). “Examples include measuring caliper diameters on bolts, defects in flat-screen TVs, shape and color of baked goods or agricultural products and critical tolerances for medical devices,” he explains.

IPD VA61 GigE-ready vision appliance has two expandable GigE camera ports and industrial I/O and processor for multiple monochrome or color GigE cameras applications. It supports resolutions 640x480 to 1,600x1,200 and Spyder 3 line-scan cameras that have dual-line-scan technology for improved noise immunity. The VA61 can power and drive cameras locally via dedicated camera I/O connections or interface with them remotely using Ethernet only.

Dalsa

514/333-1301

NI 1744, 1762 and 1764 smart cameras are shipped with NI Vision Builder for Automated Inspection interactive software and integrate with LabView and the NI library of image processing and machine-vision algorithms. A 533 MHz PowerPC powers NI 1744, with a high-resolution image sensor that acquires images up to 1.3 megapixels (1,280x1,024). NI 1762 has a 720 MHz TI DSP coprocessor alongside the 533 MHz PowerPC. NI 1764 offers the highest resolution and performance, featuring the 1.3 megapixel sensor and the 720 MHz coprocessor.

National Instruments

800/258-7022

The iVu series TG image sensor combines the simplicity of a photoelectric sensor and the intelligence of a vision sensor. It offers three advanced sensor types in one compact, rugged package, integrated or external lighting, 68.5-mm LCD touchscreen, software emulator to program the iVu off-line, 752x480 CMOS imager, remote teach function, onboard USB port for upload/download to USB drive and inspection/system logging for rapid analysis.

Banner Engineering

888/373-6767

CV-5000 vision system has a 5-megapixel camera for transferring ultra-high-definition images in 61.2 msec. Connecting extra lighting controllers or camera expansion units to either side of the base controller creates a solution without added PLC programming or wiring. New algorithms detect foreign objects or burrs on irregularly shaped profiles and filter out glare or background noise. The controllers have built-in statistical functions that let the user view the inspection results in real-time.

Keyence

888/539-3623, x.70703

Checker 3G vision sensor series in a IP67 housing can be configured for presence or measurement. Checker detects and tracks more than 6,000 parts per minute and doesn’t require a PC for setup. A SensorView teach pendant can be used to set up any number of Checker 3G sensors and can remain connected for real-time application monitoring.

Cognex

508/650-3000

Inspector I20 Flex vision sensor has interchangeable lenses and an I/O extension module with up to 16 outputs for inspecting high-speed packaging applications. The I20 offers four different lens options, and the I/O extension module enables users to program up to 19 outputs.

Sick

800/325-7425

TXG cameras with PoE over Cat. 6 Ethernet cable, up to 100m, eliminates the need for a separate power cable. Frame rates to 90 frames/sec provide resolutions from VGA to 5 megapixel. Standard functions include gain, offset and exposure time. A generic programming interface facilitates integration into an application, and SDK software provides camera control and development.

Baumer

800/937-9336

4Sight XB imaging platform with an Intel Core2 Duo processor supports full-height, half-length PCIe boards and third-party standard add-in cards for I/O and supports GigE Vision and IEEE 1394b IIDC.

Matrox Imaging

800/804-6243

With a 42x42 mm form factor and 1.45 W power consumption, NTx-Mini provides a main board for conversion of imaging data to IP packets at 1 Gb/sec data rate. It is bundled with eBus Driver, iPort PureGEV, iPort Vision suites and iPort AutoGEV software.

Pleora Technologies

613/270-0625

Sentinel Mold Protection Solution supports four cameras; each can configure five mold-inspection stages. A PC can be disconnected once inspection is configured, and the cameras interface directly with the press control, so the Sentinel monitors the press.

PPT Vision

952/996-9500

ZFX machine vision sensor in one- or two-camera models condenses image-processing know-how into recipes that let users select from auto-list options. Hardware consists of a camera with intelligent lighting and a controller with built-in HMI. A three-step procedure reduces setup.

Omron Electronics

866/88omron

Intelligent, compact vision system SBOC-M/SBOI is an alternative to high-speed cameras for diagnostics and monitoring of fast-motion sequences on high-speed production equipment. It simplifies fault localization, integrates into existing installations, connects via Ethernet and has a sampling rate of 185-2,000 images/sec.

Festo

631/ 435-0800

Nerlite LT430 backlights deliver high image-processing contrast with continuous or strobe operation for static to high-speed operations to verify presence or absence of component properties and for measuring, edge highlighting and component positioning or identification.

Siemens Energy & Automation

800/siemens

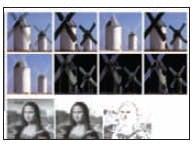

Open source program library OpenCV is adapted for VC smart cameras to increase their application range and includes many algorithms enabling movement detection, facial recognition, object tracking, contour processing and image segmentation.

Vision Components

603/598-2588

Sharpshooter optical sensor combines the flexibility of a vision system with the simplicity of a photoelectric sensor for inspection and error proofing. It provides positive verification of product count, part inclusion or identification, product configuration, and label inspection, plus verification of virtually any specific product feature. A built-in and lockable focus adjustment lens ring makes it easy to aim and focus.

Balluff

800/543-8390

MVS color system with a compact controller supports up to three cameras. Controller has a built-in 4.3-in. TFT color monitor and on-board digital input and output connections including USB and serial. Simple, straightforward programming provides easy operation and setup. Built-in power supply connects to three light sources.

Optex FA

800/280-6933

CM-140GE, CB-104GE, CM-200GE and CB-200-GE digital, progressive-scan CCD cameras and the C3 Camera Suite let users switch from camera to camera, and tier to tier, depending on application and environment needs. The cameras belong to the C3 Compact entry-level product series with a small form factor and a single-tap high frame architecture.

JAI

408/383-0300

Embedded Application System (EASY) industrial computer and machine vision implementation platform runs on Windows XP/XP Embedded or Linux on Celeron-powered units with four USB 2.0 ports, one GigE interface and VGA display, up to Core Duo-based units with 2 GB RAM, 80 GB disk memory, DVI or VGA video, eight USB 2.0 ports, a six-port GigE switch and PoE on all channels.

Value Engineering Alliance

616/492-1252

CMOS-based machine vision camera includes 12-megapixel, 1.9-in. CMOS monochrome progressive scan sensor. CleverDragon CSC12M25BMP19 camera’s CMOS sensor features 4096x3072-pixel resolution, along with 25-frames-per-second (fps) full-frame speed and a signal-to-noise ratio that is close to a traditional CCD. The development environment for the CSC12M25BMP19 is includes Camera Link standard interface (10/8 bit). Other features include large square pixels (6x6µm), an aspect ratio of 4:3, 2000 lx (F5.6) sensitivity, wide dynamic range and RDM trigger shutter.

Toshiba Teli America

949/770-teli