Hazardous locations require special enclosure considerations

A Control Design reader writes: What type of electrical enclosure is best for high humidity and extreme temperature locations, such as near saltwater? Any recommendations on design, materials or other considerations?

Answers

Ingress protection ratings

Electrical enclosures for demanding environments like temperature and humidity extremes, or near saltwater, have a number of criteria that need to be considered when designing for these use cases. A common enclosure performance criterion that is advertised is ingress protection (IP) level. This performance criterion indicates the ability of the enclosure to protect the equipment contained within it from dust and water ingress. Common IP ratings on enclosures used in outdoor locations are IP54, IP65, IP66 and IP67. The first number indicates the ability to protect against solid objects, with 5 providing a reasonable level of protection against dust, and 6 indicates no dust penetration. The second number indicates an increasing resistance to water based on spray to forceful jets or submersion.

While the increasing number generally indicates a better performance, it is important to note that IPx7 is not automatically better than IPx6. IPx7 and IPx8 are specific for submersion applications and do not guarantee the same protection as IPx6 for a high-volume forceful jet of water. Some enclosures will have a dual rating, for example IP66/67, indicating both forceful jets and submersion have been evaluated. For outdoor applications where submersion is a risk, look for a dual marked enclosure.

While the protection from dust and water ingress is important for outdoor applications, more needs to be considered. Other items include impact resistance, resistance to corrosion, resistance to sleet, frost or icing, protection from UV effects and snow loads. A UL type rated enclosure certified to UL50/50E will cover these items if the proper type is selected. UL type 3X, 3SX, 4, 4X, 6 and 6P are various types of enclosure ratings for use in outdoor applications that not only account for dust and water ingress, but also address many to all of the other noted concerns above. While there are a wide variety of enclosures made from a wide variety of materials that meet these identified performance criteria, generally enclosures made with stainless steel, like 304 or 316, using silicon gasket materials fare very well in many demanding environments.

Temperature control within the enclosure needs to be considered when designing for demanding environments. The enclosure color, material and design will affect things like solar loading or the ability for internal heat sources to be dissipated, which will directly influence internal temperatures. The use of sunshades can greatly benefit electrical enclosures that are in outdoor locations with high solar loads. However, additional cooling or heating sources may also be required depending on the outside environment. Likewise, humidity will also need to be controlled. Tightly sealed enclosures, like an IP67 or UL Type 6P may seem like it would solve the problem, but in many situations it only makes it worse. In high humidity situations, the water in the atmosphere is in vapor or gas form and will have no problem finding its way into the enclosure. Once inside of the enclosure it may have the opportunity to condense to a liquid, causing shorts and possibly filling the enclosure with standing water. Using breathers and drains as well as possible heaters, dehumidifiers or other means to control the humidity and condensation within the enclosure is needed, especially in areas where there are wide temperature swings and high humidity.

If the enclosure is for an application in a hazardous (classified) location, then additional certifications may be required depending on the protection concept being used. For applications based on zone classification in the United States, the enclosure will need to be certified to UL 60079-1, for flameproof Ex “d” applications, or to UL 60079-7 for increased safety EX “e” applications when protection for gas or vapor. For dust hazard applications, UL60079-31 for protection by enclosure Ex “t” is required. In class/division locations, a standard listed enclosure may be acceptable in division 2. If there are no ignition sources within the enclosure, see NEC 500.8 (B)(3). Otherwise the enclosure will need to be rated as explosion-proof and/or dust-ignition-proof to UL1203 or FM 3615/FM3616 depending on the hazardous material class.

Lastly, consider all entries, blanking plugs, windows and other items that complete the enclosure with the same level of concern as selecting the enclosure. It is important to not overlook these items and negate any protection the enclosure would otherwise provide. This is especially true for hazardous-area applications. Being consistent in all aspects is key to maintaining a particular level of protection. For example, a UL Type 4X enclosure with even a single unrated sealing washer may no longer provide Type 4X protection to the equipment contained within.

Ryan Brownlee / global compliance and technology consultant / Pepperl+Fuchs

UL-listed enclosures

For an enclosure in a hot, humid and possibly salty environment, I would suggest choosing a UV stabilized polycarbonate enclosure. An ingress protection rating of IP67 or IP68 is strongly recommended to ensure the best resistance to the elements. Verify that hardware is of high-grade stainless steel and that the gasket is of a silicone composition. I always recommend UL-listed enclosures from a reputable manufacturer when it comes to these types of extreme conditions to ensure the enclosure meets standards and the company will stand behind its products.

Other hardware attributes to consider include noncorrosive materials such as brass or zinc coating. Additional protections can include O-rings or plastic, rubber or silicone hole plugs. Pay close attention to torque specs if the manufacturer specifies torque ratings of fasteners, as under-tightening or over-tightening can both cause leaks or enclosure malfunction.

It is best to design the sealing area inside of the fasteners to establish the best sealing environment possible. If additional holes are necessary in the enclosure, be sure to match or exceed the IP rating of the enclosure by using IP-rated hole seals and grommets, or seal well with an environmentally resistant epoxy or silicone material. All enclosure assemblies should be properly tested prior to installation in the field to ensure proper fitment.

Cody Knutson / product manager II / Digi-Key Electronics

Strength of stainless steel

The need to protect critical equipment in corrosive environments requires a higher level of protection than painted carbon steel enclosures can provide. Stainless-steel enclosures fill this void with superior strength and corrosion-resistant properties. Stainless enclosures are built to keep out various elements in mild and extreme conditions. They can be used for indoor and outdoor applications that require protection from corrosion, rust and various harsh weather conditions.

You need to look for an enclosure that was designed with strength and durability in mind for use in extreme applications. Considerations that you should look for include:

- 316L stainless steel alloy, which is suitable for environments with saltwater corrosion (other stainless steel alloys including 304 are not suitable)

- continuous foamed-in place gasket for a water- and dust-proof seal

- tested and certified to IP66 and UL Type 4X requirements.

Nick Tamizifar / vertical market manager—process industries / Rittal North America

Degrees of protection

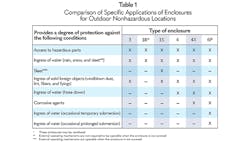

Enclosure ratings are dependent on what exactly is needed in your specific situation (see Figure 1). A NEMA 4 rating has a dust-tight and water-tight door gasket seal to protect against any windblown dust or water. This enclosure type will also remain undamaged by formation of ice. Standard enclosure gasket seals are tested for their performance, from -22 °F to 140 °F.

As for design recommendations, a sun shield, which is a layer of metal spaced away from your enclosure, could be attached to the enclosure on all exposed sides protecting it from direct rays while allowing air to pass across the enclosure. A drip shield will help protect the door from heavy or prolonged exposure to rain and protection of the damaging effects of ice.

For your material considerations, the effects of saltwater can be extreme even with type 304 stainless steel although the effects are more cosmetic than structural or functional. If cosmetics are critical, then type 316 stainless steel may be a better choice, yet it too is not impervious to rust and staining caused by airborne debris and chemicals that may end up on the material surface.

Zac Titus / design and marketing / Saginaw Control & Engineering

Plastic enclosures and venting

When selecting or designing electrical enclosures, material selection and enclosure design for the specific application is critical. Most outdoor enclosures on the market are made from metal (aluminum, stainless steel), plastics like outdoor-rated polycarbonate grades or fiberglass. Each material has its benefits and drawbacks related to corrosion/chemical resistance, mechanical strength, thermal/electrical properties and/or cost. Evaluating which areas are most important to your application will help you narrow your material selections.

For example, with saltwater exposure, materials like stainless steel or plastic enclosures are typically chosen because of their corrosion resistance. But a polycarbonate enclosure would lower the applied cost of your product, while providing excellent impact resistance compared to other polymers. When using plastic materials in an outdoor environment, it is also good to utilize a material that is UL 746C f1-rated.

While materials are a focus point for enclosures, design features should not be overlooked. Ingress protection for dust and water should be evaluated via IP (IEC 60529) or NEMA 250 ratings and chosen to meet your application requirements. Keep in mind that each rating requires testing by a different method, so an enclosure that only meets an underwater IP67 (NEMA 6) rating might not be the right solution for a high-pressure, spray-down IP66 (NEMA 4) application if both ratings are not stated. Evaluation of a plastic enclosure should include UV resistance, flammability rating, impact rating and operational temperature requirements.

Venting is also an important design feature that most people overlook, but it is especially important if your application includes rapid temperature swings, such as air temperature to enclosure surface temperature or even internal temperature swings based on the electronics. These fluctuations can cause pressure build-up inside the enclosure and continuous stress to the seal. Over time, this allows ingress of water or other particles into the enclosure. Venting will allow any moisture inside of the enclosure to dissipate through the membrane and protect the sensitive electronics inside of the enclosure.

Your application requirements will lead to the right material and design for your enclosure.

Jeremy Schaffer / product manager —DCS enclosures and solutions / Phoenix Contact Development and Manufacturing

About the Author

Anna Townshend

Managing Editor

Anna Townshend has been a writer and journalist for 20 years. Previously, she was the editor of Marina Dock Age and International Dredging Review, until she joined Endeavor Business Media in June 2020. She is the managing editor of Control Design and Plant Services.