How multi-brand ecosystems embrace open data and bridge the digital gap

Key Highlights

- Sandvik Coromant’s integration into MachiningCloud provides manufacturers with direct, digital access to the world's largest cutting tool catalog for streamlined tool selection and assembly.

- Open, multi-brand digital ecosystems allow machine shops to build complex tool assemblies using components from different manufacturers within a single digital twin environment.

- Seamless data flow between MachiningCloud and CAM software, such as Mastercam and ESPRIT, virtually eliminates manual data entry, reducing dead time and human error during the programming phase.

Ecosystems continue to proliferate in the industrial automation space. From Universal Robots’ UR+ and Bosch-Rexroth’s ctrlX World to Schneider Electric’s EcoStructure and Rockwell Automation’s PartnerNetwork, the heavy hitters have laid the groundwork for bringing components and the data shared by those components into a harmonized environment.

Data has quickly become the darling of manufacturing operations. Every aspect of the process, from design to predictive analytics, can benefit from better data (Figure 1).

Those same principles and benefits have made their way into the CNC machine tool realm with the MachiningCloud ecosystem, which reached a significant milestone in January when Sandvik Coromant, the world’s largest cutting tool manufacturer and part of the $30 billion Sandvik Group, became part of the ecosystem.

“Manufacturing environments are diverse, and customers value the freedom to choose how they work across different digital experiences,” explains Tobias Unosson, business and partner development manager at Sandvik Coromant (Figure 2). “Through the collaboration with MachiningCloud, Sandvik Coromant offers an additional channel to meet customers where they are, giving them the flexibility to access and consume its products and tooling data across multiple platforms and workflows.”

The full Sandvik Coromant tooling catalogue has been on MachiningCloud since its January 27 launch, providing essential product data for tool selection, CAM programming and manufacturing workflows, explains Unosson. “Moving forward, we will focus on continuous updates, maintenance and enrichment to ensure data accuracy and meet evolving customer needs,” he adds.

“The collaboration is already delivering value, with Sandvik Coromant’s primary catalog of cutting tools and holders live on the platform,” notes Matthew Nicholson, director of sales & marketing at MachiningCloud (Figure 3). "We are working closely with their technical teams to roll out more complex 3D models and advanced application data in strategic phases throughout 2026. This ensures that every piece of data we host is fully validated and ready for immediate use in the customer’s digital workflow."

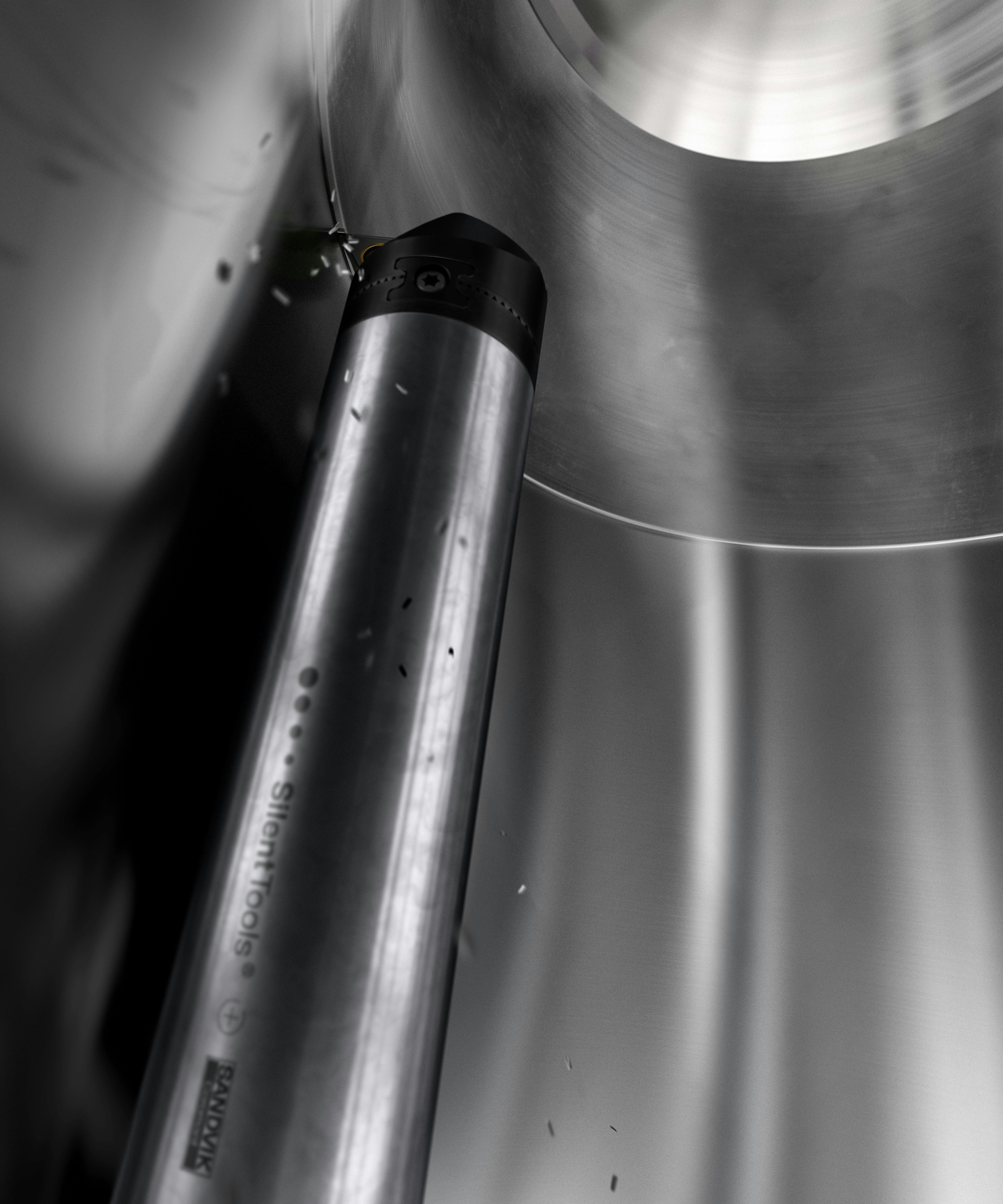

Sandvik Coromant's addition of its tooling data to the MachiningCloud cloud-based platform will allow users to find tools, build assemblies and export data directly to CAM systems, streamlining process planning (Figure 4). "This collaboration puts ready-to-use Sandvik Coromant tooling data into the hands of CAM programmers, helping reduce guesswork and keep production moving," says Paul Ricard, president and co-founder at MachiningCloud.

"This partnership reflects our ongoing commitment to improving access to high-quality tooling data," explains Unosson. "By expanding availability in customer-preferred platforms like MachiningCloud, we help reduce friction in tool selection and support our customers in taking their machining process to the next level."

Sandvik Coromant joins more than 60 other brands, including fellow Sandvik Group members Dormer Pramet, Seco and Walter, alongside other cutting-tool companies such as Iscar, Guhring, Tungaloy and Kyocera SGS, in a global digital ecosystem. "We are proud to offer the most comprehensive and diverse brand-neutral library available to the manufacturing industry," says Nicholson.

"The real-world advantage is the massive reduction in dead time during the programming phase," says Nicholson. "Modern machine shops rarely rely on a single supplier, and MachiningCloud is the only platform that allows users to build complex, multi-brand tool assemblies in one place. Instead of hunting through various manufacturer websites, users can source a Sandvik Coromant insert, pair it with another brand’s holder and have a complete digital twin ready in seconds."

The ultimate goal is to bridge the gap between the manufacturer’s data and the shop floor. "With over 20 export partners, including industry leaders like Mastercam, ESPRIT, TDM Systems and Zoller, we ensure that this data flows seamlessly into the user’s existing software environment," explains Nicholson. "By centralizing this information, we help our customers eliminate manual data entry, reduce human error and get to the first chip much faster."

About the Author

Mike Bacidore

Editor in Chief

Mike Bacidore is chief editor of Control Design and has been an integral part of the Endeavor Business Media editorial team since 2007. Previously, he was editorial director at Hughes Communications and a portfolio manager of the human resources and labor law areas at Wolters Kluwer. Bacidore holds a BA from the University of Illinois and an MBA from Lake Forest Graduate School of Management. He is an award-winning columnist, earning multiple regional and national awards from the American Society of Business Publication Editors. He may be reached at [email protected]

Leaders relevant to this article: