How to choose a diode to mitigate back EMF in industrial control circuits

Why this article is important

- It explains the phenomenon of back EMF, which can damage PLC outputs and relay contacts, crucial for ensuring reliable machine operation.

- It details practical solutions like using flyback diodes for dc circuits and MOVs for ac circuits.

- It emphasizes the importance of properly sizing protection components, such as diodes and MOVs, based on current and voltage ratings.

- It highlights the need to understand whether relays or solenoid valves have built-in back EMF protection, ensuring appropriate protection measures are implemented during system design.

A starship moves through the neutral zone on a routine survey mission. The captain and the crew are busy performing their normal duties when, suddenly, sensors detect an enemy vessel approaching with their shields up and weapons locked.

The captain quickly reacts with an order to fire an energy pulse at the ship. The lieutenant commander locks on and fires.

Lieutenant commander: “Captain, we have fired an energy pulse at the target. Their shields absorbed the pulse, and that has created a large electromagnetic field. This field has collapsed and has sent the energy pulse back at us.”

Captain: “Shields up! Prepare for impact!”

The captain is, of course, correct to raise shields. A returning energy pulse can be very damaging. This is a bit of fiction, but it is also a description of what happens whenever a solenoid on a relay or valve is turned on and off by a controller output. It generates a pheonomenon called a back electromotive force (EMF).

What is a back EMF?

A solenoid is a coil of wire that creates a magnetic field whenever current passes through it. The magnetic field then triggers relay contacts or a valve to change state. This field is maintained as long as current flows through the coil.

When the current is switched off, the magnetic field collapses. This collapse induces a reverse polarity voltage in the coil, which is the back EMF. This voltage travels back to the source, which in many cases is the output of a programmable logic controller (PLC) and can damage an unprotected output circuit.

How does this cause damage?

The voltage spike from a back EMF can cause damage in several ways. If the output circuit is a set of relay contacts, it can cause these to arc. Arcs create small pits in the surface of the contacts. The pits make the arcing worse and the effect amplifies over many cycles until the contacts no longer make a good connection.

A voltage spike to a transistor output can damage the circuit components by overloading them and causing them to fail.

Even if the components are not damaged, the spikes can act as transient noise forced into the circuit and can cause unpredictable behavior.

Key takeaways

- Back EMF from inductive loads like solenoids can cause significant damage to PLC outputs and relay contacts if not properly mitigated.

- Implementing flyback diodes in dc circuits and MOVs in ac circuits is essential for protecting control systems from damaging voltage spikes.

- Careful selection of protection components, considering current, voltage and power ratings, is crucial for reliable and long-lasting machine operation.

- Always confirm whether relays and solenoid valves have built-in back EMF protection, and consult datasheets to ensure proper protection is implemented.

How do we raise shields?

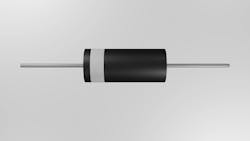

For a direct current circuit, a diode placed between the positive side of the coil and ground will dissipate the returning voltage spike. Since the voltage spike will be reverse polarity from the source, the diode should be reverse biased so that the cathode end—the end usually marked with a ring—is connected to the positive side of the coil, and the anode end should be connected to ground. This diode is sometimes called a flyback diode or a snubber.

The important parameters for choosing a diode are the peak current rating and the peak reverse voltage. A good selection criteria is three times the current and voltage ratings of the circuit.

Another necessary consideration is the maximum total dissipation or the amount of power, in Watts, the diode can handle. A 1N4004 diode is rated at 3 W and is a good choice for a 24 Vdc system.

For alternating-current (ac) circuits, a metal oxide varistor (MOV) should be placed in parallel with the coil. A MOV should be selected so that the voltage rating is at least 125% of the source voltage. Once the voltage level in the circuit exceeds the MOV voltage rating, the MOV acts to dissipate the additional energy.

Get your subscription to Control Design’s daily newsletter.

At the normal voltage level, the resistance is very high. Above this level, the resistance reduces to allow current flow. MOVs can also be used for direct current circuits.

When choosing a MOV for your application, the size of the disk is important. The larger the disk size, the higher the maximum amount of current the MOV will withstand. The device datasheet will list the maximum current or the nominal current rating. This can be tricky, in that the nominal rating is typically about one half of the maximum current rating. It is much better to overestimate the current requirement than to underestimate it.

When purchasing relays with dc coils, many of them are available with diode protection built in. Relays with ac coils and solenoid valves usually do not offer back EMF protection. Whether you are designing a system or just replacing a failed part, know what the options are and ensure you are using the correct components. Consult the data sheet to be sure.

When it comes to protection of output controllers, always heed the captain’s order, and make it so. Your “starship” will serve you for many years to come.

Next steps

- Review existing PLC output circuits and relay/solenoid connections to identify any unprotected inductive loads that could be generating back EMF.

- Calculate the required diode or MOV ratings for each identified inductive load, ensuring they meet or exceed the recommended safety margins.

- Source and install appropriate flyback diodes or MOVs on unprotected circuits, prioritizing critical control system components.

- Update documentation and standard operating procedures to include back EMF protection considerations for future designs and maintenance.

About the Author

Larry Stepniak

Flint Group

Larry Stepniak is electrical engineer at Flint Group. Contact him at [email protected].

Leaders relevant to this article: