PLCopen increases integration of control platforms

The PLCopen Process Industry Working Group’s goal is to accelerate process control and automation efficiency leveraging the IEC 61131 programming standard. The PLCopen Process Industry Working Group adds IEC 61131 process automation standard functions including the Open Process Automation Standard (O-PAS) functions and certifications. This is designed to enable application engineers to deploy programmable logic controller (PLC), distributed control system (DCS) and open platform controls in process industry applications.

The cost of programming process automation and control systems continues to grow and is a significant part of project costs that are lowered with PLCopen standards and certifications, noted Bill Lydon, director PLCopen North America and a digital manufacturing transformation Industry 4.0 consultant. PLCopen standardization and modular methodology decreases training time, application development costs while reducing project cost overruns, he explained.

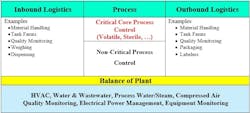

Process plants have a significant amount of discrete control applications in many areas including inbound logistics, balance of plant, and outbound logistics, Lydon continued. The PLCopen Process Industry Working Group harmonizes discrete and process control to enable flexible and modular process automation systems with unique functions that do not follow a single worldwide standard. This increases training, application development costs and project profit risk, he noted.

This further expands the base of PLCopen standards that enable no-code/low-code industrial automation programming across vendor platforms, including industrial computers. This will include incorporation of the function blocks defined in the O-PAS standard into a new PLCopen standard.

Harmonized control and automation

Harmonization of discrete and process programming makes training, application development and projects more efficient, continued Lydon. There are a diverse number of ways to program applications for process control and automation. The goal is to develop PLCopen function block standards for process control functions. Function blocks are encapsulations of variables, parameters and their processing algorithms. Similar standardization has been done with PLCopen standards developed for motion control, safety, fluid power, XML program interchange and OPC UA.

Get your subscription to Control Design’s daily newsletter.

Since the capabilities of programmable logic controllers extend far beyond those of the original 1970s relay-replacement applications, many process control applications are now done with PLCs. The emerging use of industrial edge computers with IEC 61131 runtime software engines is another segment that benefits from the results of the PLCopen Process Industry Working Group, explained Lydon (Table 1).

PLCopen standards and certifications

PLCopen has been successful defining IEC 61131 functions and certifications used widely throughout industry worldwide increasing engineering efficiency and quality and empowering a wider number of people in motion control, fluid power, safety and other functions, explained Lydon (Figure 1).

PLCopen is a worldwide non-profit organization designed to provide efficiency in industrial automation based on the needs of users. It was founded in 1992 and has its headquarters in the Netherlands with supporting offices in the United States, Japan and China. A list of members, as well as the PLCopen Process Working Group details, can be found on the PLCopen website.

A physical and virtual kick-off meeting will be held January 20-21 in Wernigerode, Germany. Contact PLCopen Managing Director Roeland Hagesteijn at [email protected] for details.