Connector system harnesses machine flexibility

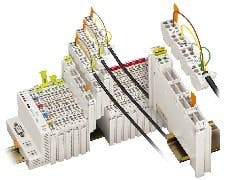

YOU'VE HEARD FROM many circles that your machines have to be more modular and flexible than ever before, and, as a result, must incorporate components that promote rapid-fire physical changeovers. This clearly includes the control system wiring, so the move to pluggable connections for I/O modules is underway.Wago Corp. says it has the products to help. The company expanded its Wago-I/O-System to offer pluggable connectors for I/O module wiring. They say this new 753 Series allows customers not only to glean the benefits of 750 Series I/O flexibility but, also let’s them take it a step further with pluggable wiring.“We first noticed this growing industry trend for pluggable wiring--for part or all of the control system wiring--with our terminal block products and we’ve now addressed this need with our Fieldbus I/O and PLC products,” says Dean Norton, Wago’s marketing manager.As a result of this change, customers now can pre-manufacture their wiring harnesses using the 753 Series connectors and simply plug them into the 753 Series I/O modules. A variety of both analog and digital modules are available. This serves to simplify installation and reduce wiring errors in the field. |The company points out additional features and benefits of this system:

- Both the I/O module and the corresponding connector have an overall combined dimension of 12-mm wide by 64-mm high by 100 mm deep, only 1-mm taller than the original 750 series I/O modules.

- Built into the connector and I/O module are orange pull tabs that allow fast, easy, and tool-free removal of either the connector or the I/O module individually.

- Built-in test points at every connection point allow fast, easy and safe testing of the I/O. The test point is completely shrouded to hold and stabilize the test probe.

- Integrated strain-relief supports the pre-harnessed cable and ensures that the integrity of the connection between the connector and the I/O module is maintained. The strain-relief is accomplished via a loop built into the connector and use of a cable tie.

- Integrated coding allows up to 16 different coding possibilities.

Norton adds that all connectors use CAGE CLAMP spring-pressure termination technology for maintenance-free wiring that is vibration-proof, corrosion-resistant, thermal cycling-resistant, and up to 50% faster than wiring with screw technology. The 753 Series pluggable I/O modules are said to be 100%-compatible with the original 750 Series I/O modules and bus-couplers. Consequently, customers can mix both 750 Series and 753 Series in the same I/O node. This allows customers to choose whether or not to make all functions on the node pluggable or to keep some functions that should not be tampered with as non-pluggable. “Another useful reason for having both pluggable and non-pluggable I/O wiring is to indicate which of the I/O modules are wired to devices internal to the control cabinet--contactors or relays, for example--and which ones are wired to devices such as sensors and actuators on the machine, external to the control cabinet,” adds Norton.Compatibility with the 750 Series also gives these I/O modules complete access to Wago’s extensive line of fieldbus bus couplers. The offering includes ECO couplers, a lower-cost solution for highly distributed applications; the original couplers, which allow connection of up to 256 I/O points in a combination of digital, analog, and special function I/O; and the programmable fieldbus couplers that offer full PLC capability in both standalone or distributed control applications. In addition, the couplers are offered in a variety of protocols including Ethernet TCP/IP, EtherNet/IP, DeviceNet, Profibus, Modbus, CANopen, and more.“By developing the 753 Series pluggable I/O modules, and making them compatible with the 750 Series,” concludes Norton, “Wago is helping to provide fieldbus users the utmost in flexibility--whether in wiring options, fieldbus selections, modularity, granularity, or signal types.”

For more information, call 800/346-7245, e-mail [email protected]; or browse to www.wago.com.

| Wago Contact Information |