Bosch Rexroth looks back on linear axes development

Over the past three decades, Bosch Rexroth’s portfolio of ready-to-install linear axes has been developed on an ongoing basis. In response to customer requirements, it now focuses on electrification and connectivity. With today’s linear motion technology components in combination with sensors, electronics and software, the company offers mechatronic solutions for the Factory of the Future.

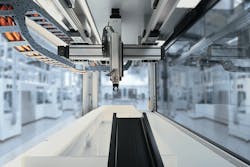

Multi-axis solution with linear axes from Bosch Rexroth (Source: Bosch Rexroth AG)

"With our 30-year history and over a million ready-to-install linear axes sold, we have a wealth of experience," said Ulf Lehmann, head of business unit linear notion technology at Bosch Rexroth AG. "We offer a complete range of linear motion technology solutions – from simple components to smart mechatronic solutions and subsystems."

According to the company, Bosch Rexroth’s linear motion technology division is now taking the next step towards the Factory of the Future with the Smart Function Kit for joining and pressing applications, a ready-to-install mechatronic system kit that allows straightforward online product selection/configuration and reduces the engineering outlay. The plug and produce approach aims to reduce commissioning times and remove the need of the user having programming knowledge.A Smart Function Kit for handling applications or a sensor-supported compensation module that increases the precision of handling robots and Cartesian systems is coming in the future. This Smart Flex Effector offers independent kinematics in six degrees of freedom.

“Our wealth of experience in this product area, our global presence and our ongoing dialog with customers who are becoming more and more involved in the agile development process are key factors in our success,” said Lehmann. “Users benefit from modern eTools, a comprehensive portfolio of mechanical, drive and control systems from a single source and ready-to-install subsystems.”

At the start of the 1960s, Bosch Rexroth began developing linear bushings, shafts, slides and transfer tables as prototypes. The first two complete linear modules with linear guides in combination with a ball screw assembly and toothed belt drive as a ready-to-install subsystem were launched in 1990. In 1996, they were followed by carriages with an integrated runner block. This in turn led to the introduction of the compact modules which offer high performance yet take up less space.

With the electromechanical cylinder (EMC), the company began electrifying actuators in 2007. These actuators replaced the conventional pneumatic solutions that had a higher energy consumption. In 2018, Bosch Rexroth presented the integrated measuring systems IMS, integrated into linear axes. The solution is largely immune to interference and offers high precision and integrability.

The way the company works with users has changed too, for example through the introduction of CAD systems, 3D models, product configurators and modern eTools such as the selection and sizing tool LinSelect which was developed in 2016. This allows axis dimensioning and selection and guides engineers to the optimum linear axis with just a few mouse clicks.