CiA elects new board, approves budget during annual assembly

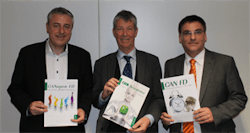

CiA’s board of directors (from left to right): Christian Schlegel, Holger Zeltwanger, Uwe Koppe

The CAN in Automation (CiA) associations’ members elected its board of directors during its annual general assembly on March 14. New business director is HMS's Christian Schlegel while technical director, Uwe Koppe from Microcontrol and CiA managing director Holger Zeltwanger were re-elected.Emtas, ESD, Janz Tec, Microcontrol, and Vector are part of the CiA business committee. while the technical committee includes Bosch Automotive Electronics, ESD, HMS, Infineon, and Vector.

The budget for 2017 was accepted unanimously. According to CiA, membership fees are mostly spent for developing CANopen and CAN FD specifications as well as to support the international standardization. The nonprofit association’s income is also used for promoting activities such as stands at EmbeddedWorld in Nuremberg, SPS IPC Drives in Nuremberg, Interlift in Augsburg, and IAS in Shanghai. Of course, a part of the membership fee is used for the free-of-charge technical "hotline."