Universal Robots Unveils New UR3 Collaborative Robot

As the Automate 2015 show floor opened in Chicago Monday, March 23, Universal Robots simultaneously unveiled its newest collaborative robot of the UR family, the UR3.

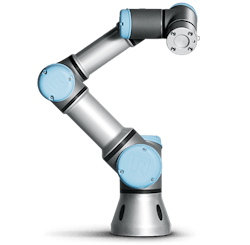

The UR3 is a light, 6-axis, table-top robot that offers flexibility and position accuracy in a compact form.

Source: Greta Lieske

Esben Oestergaard, CTO and co-founder of Universal Robots, revealed the new UR3 at the Universal Robots booth in McCormick Place, Chicago this past Monday. He called it a "third-hand"-type of help. According to Universal Robots, the UR3 is a light, 6-axis, table-top robot, offering flexibility and position accuracy in a compact form. It's suited for automated precision tasks where people and robots are working side-by-side."It is a robot that is extremely well designed to fit into very confined spaces," Oestergaard explained, adding it's a main reason the UR3 was added to the UR family − so there is an option for minuscule spaces. "What's important here is that we now have a robot that is second-to-none when it comes to [collaborative] technology ... safety and programming, but it's also coming out at a price point that is competitive."

According to Universal Robots, with the UR3 there aren't the traditional added costs of robot programming, set-up and dedicated shielded work cells. Applications the UR3 can be used for include the following: assembly, soldering, gluing, screwing, painting, pack and place, operating hand tools, laboratory work, and more.

About the Author

Greta Lieske

digital editor

Leaders relevant to this article: