M2M Devices to More Than Double in Oil & Gas

The oil and gas industry, perhaps more than any other, is characterized by remote and inaccessible facilities where wireless communication is the only viable option for transferring machine-to-machine (M2M) data.

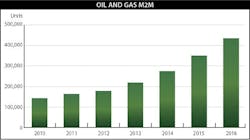

The number of devices with cellular or satellite connectivity deployed in oil and gas applications worldwide is expected to rise at a compound annual growth rate (CAGR) of more than 20% over the next several years — from 164,000 at the end of 2011 to 435,000 by 2016, according to Berg Insight. Cellular-based M2M devices are expected to count for almost two-thirds of the nearly half million devices at the end of the forecast period.

As Berg Insight notes in its report, wireless technologies such as private radio, cellular and satellite communication can provide ubiquitous online connectivity at reasonable cost and deliver good performance and availability. This enables the delivery of operations management, equipment management and regulatory compliance applications linking remote equipment and enterprise IT systems.

Telemetry and M2M solutions can be found in applications such as monitoring and controlling of drills, wells and pipelines. North America is the forerunner in the use of wireless M2M solutions in oil and gas applications, accounting for almost half of the worldwide device shipments.

Wireless M2M applications in the oil and gas industry have entered a growth phase that will last for several years to come, Berg Insight predicts. Analysts estimate that the shipments of oil and gas M2M devices with cellular or satellite communication capabilities will almost triple in coming years, from 33,000 in 2011 to 126,000 in 2016. Onshore well-field-equipment monitoring and in-land-pipeline monitoring are expected to be top two applications for wireless M2M in the oil and gas industry.

Many factors are driving the M2M market in the oil and gas industry, including new regulations, rising operating costs due to increasingly inaccessible reserves, and accelerating competition between international oil companies (IOCs) and national oil companies (NOCs). "Demand for improved operational efficiency and new governmental regulations will push the adoption of wireless M2M in the industry," said Johan Svanberg, senior analyst for Berg Insight.

Advanced SCADA and wireless M2M solutions can help stakeholders to comply with regulations and meet the high demands on security and efficiency that come with oil and gas operations. "Wireless M2M, remote automation, control and monitoring are also key ingredients in order to make it cost effective to extract, transport and distribute emerging oil and gas products, including LNG and unconventional resources such as shale gas and heavy oil," Svanberg said.