Robotics combines with distribution technology platform for new automated warehouse project

A new partnership between Hai Robotics and Hy-Tek Intralogistics has created its first joint automated storage and retrieval system (ASRS) for a manufacturing customer in Ohio. The new system is driven by Hai Robotics autonomous case-handling robot (ACR) systems, which are compact tote retrieval robots that navigate a storage grid. The partnership delivered distinctive ASRS features, including three varied heights of the racking, two different size totes and double deep tote storage.

The system was designed for a goods-to-person buffer system application and will automatically store drill bits, machining parts, and raw and work-in-progress goods. The ACR system delivers to a single dual-purpose workstation and conveying systems, working with Hy-Tek’s IntraOne software.

ACRs are compact, tall tote retrieval robots that can extend upward to manage the storage of goods 32+ feet high. They are material agnostic, meaning the equipment can manage a grid constructed of almost any standard racking and container type, size and material. Without the requirement of high-precision storage locations, facilities typically see higher system flexibility and ease of expansion with lower overall costs, Hai Robotics said.

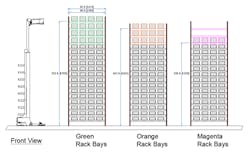

The new automated facility has variable ceiling heights and other obstacles like pipes, lights and sprinklers, that created inconsistent vertical clearance. The Hai Robotics/Hy-Tek ASRS has three racking heights: 22 feet, 20.5 feet and 17.5 feet (Figure 1).

The ACR-driven ASRS can handle two different size totes within a single system. The length and width of each tote is the same but have variable heights based off the products that are stored within them. If the system only had the large totes, it would be undersized with lost storage space. Similarly, only the smaller totes would exclude some product sizes. With flexibility, the system can be appropriately sized to consolidate much of the facility’s storage needs, Hai Robotics said.

The A42TD ACR, the robot model that manages this ASRS, has a double deep reach, so the robot can reach two totes deep into racking. Totes can be stored four deep and retrieved on either side of the rack. This reduces the number of aisles and condenses the storage footprint.

Kyle Detwiler, technical sales manager at Hai Robotics, stated, “Creativity is key component of the solution that Hy-Tek provided. The Hy-Tek team is able to leverage Hai Robotics as a tool to unlock greater efficiency, density and flexibility for the customers' operation."

“Pairing Hai Robotics’ system with our IntraOne software allows for an incredibly flexible solution to be implemented for our client,” said Matt Bommer, general manager, Cleveland operations for Hy-Tek Intralogistics. “Few robotic solutions allow for multiple totes sizes and heights in the same system.”