Keysight Americas labs receive ISO/IEC 17025 accreditation

Keysight Technologies announced that Keysight Americas ' 19 service centers in the United States, Brazil, Canada and Mexico have received accreditation for the 2017 version of ISO/IEC 17025 by the ANSI National Accreditation Board (ANAB), the largest multi-disciplinary accreditation body in North America. The company also released its Keysight Test Equipment Report which is about the impact of poor testing practices for businesses.

ISO/IEC 17025 is the primary international standard for establishing laboratory competence and quality. The latest version of the standard to ensure calibration accuracy was published in 2017. ANAB assessors evaluate a laboratory 's ability to produce precise, accurate test and calibration data. As part of the accreditation ANAB assessment, the best accuracy (lowest measurement uncertainty) is established for each measurement parameter in a scope-of-accreditation.

"Keysight metrologists and quality experts work with and inside standards committees to ensure we meet evolving calibration standards in our laboratories," said Tom Ludden, general manager of Keysight's managed services division in the Americas. "Keysight strives to provide our customers with accredited calibration services so they can manufacture the highest quality electronic hardware."

The Keysight Test Equipment Report is based on a survey conducted by Dimensional Research consisting of 306 participants that use test equipment for ensuring electronic device quality and testing. According to Keysight, the survey sought to understand the current challenges for achieving electronic hardware manufacturing quality.

According to the survey, 64% of respondents confirmed that ensuring product quality is growing more difficult due to the increased complexity of electronics, and the corresponding complexities of testing required to measure quality. Respondents reported that quality challenges originate from growing customer demands and tighter tolerances to increasing manufacturing complexity and pace.

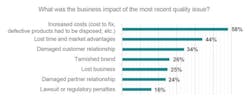

Ninety-two percent of survey respondents said that they suffer significant business impact from error-prone test equipment. Survey respondents report that quality issues frequently impact the bottom line, citing increased costs to repair or dispose of defective products and lost business, potential lawsuits and regulatory penalties, as well as lost time-to-market or market advantages, damaged customer relationships and a tarnished brand.