A variable frequency drive (VFD), being a non-linear load, is a source of harmonics on the power line. Harmonic current causes additional heating of the transformer and cabling to the VFD, which reduces the capacity of the cable and transformer. An ac line reactor or dc link reactor (dc choke) is used to mitigate the impact of harmonics in VFD applications.

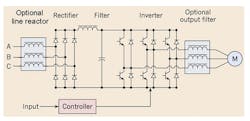

The ac line reactor is connected in series with the incoming power line while the dc link reactor is connected after the input diode in the VFD circuit (Figure 1).

Figure 1: The ac line reactor is connected in series with the incoming power line while the dc link reactor is connected after the input diode in the VFD circuit.

While both the ac line reactor and dc link reactor reduce the impact of harmonics, there are advantages and disadvantages for using one or the other (Table 1).

Prior to selecting an ac line reactor or a dc link reactor for mitigating the impact of harmonics in VFD applications, it is prudent to carefully review the advantages and shortcomings of both and select the one that is better for that particular application.

Table 1: Using an ac line reactor or a dc link reactor has its pros and its cons.

Boima Morray is director, product marketing and management, at Vacon. Contact him at [email protected].