Precision motion control converts a massive crane into an efficient asset

Key Highlights

- Motion Australia developed a custom algorithm based on Peter Nachtwey's input shaping concept, adapted for variable speeds and changing rope lengths.

- The solution used Delta’s RMC75E motion controller and RMCTools software, enabling complex mathematical control without additional hardware costs.

- The implementation resulted in near-zero sway during crane operation, enabling precise load placement and eliminating delays caused by load oscillation.

Efficient unloading of bulk materials like fertilizer, minerals and cement clinker directly affects the regional industry north of Sydney, Australia. Before a new 30-ton unloader was installed, ships waited days while their own small cranes laboriously emptied their holds. The new machine promised to slash unloading times.

Predicting trouble

A global manufacturer of bulk material handling equipment for shipping ports won the contract to build a massive unloading machine for the port. It encountered challenges with the machine’s hydraulic system—think of it like hanging a fishing weight on the end of a nylon line. When the line moves, the weight begins to swing. Without precision motion control to dampen the swinging, the system becomes unstable and inefficient.

In need of expert consultation, Motion Australia, our specialized Australia-wide hydraulic motion control engineering company with representation and workshops in all states was called to design a solution.

The difficulties were particularly on the safety side. Part of reviewing the hydraulics was to assess the motion control performance they were expecting because not only is the machine large—able to pull up to 20-ton bites of material out of the ship—they also quoted quite a tight cycle time.

The full crane cycle needed to be completed in just 62 seconds to achieve the throughput required for the port's operational goals (Figure 1). This process included dropping the grab into the ship and retrieving material, hoisting it up, traversing it to the hopper, releasing it and returning. With a potential travel distance of 30 m, the physics demanded extremely fast and precise motion control.

When our team analyzed the proposed design, they identified serious issues with dynamic response. To illustrate the problem, we created a desktop-scale simulation that showed how the grab would swing wildly through plus or minus 6 m, oscillating for nearly 40 seconds after crane movement stopped.

If you don't control the motion properly, the grab will sway. The analysis showed that conventional programmable logic controller (PLC) functions would not provide the precision required. An advanced motion controller, such as the capabilities built into Delta’s RMC, were essential to manage the systems dynamics and prevent the instability I predicted. When the crane was put into operation, reality proved my warnings correct — the grab swung so violently that the machine became unusable.

Finding help in mathematics

Early in 2023, I received a panicked phone call. The sway had defied all attempts at mitigation, and the port was threatening drastic action.

Hope for a solution existed in theoretical work by Peter Nachtwey, former president and chief software architect at Delta Motion. His "input shaping" concept provided a mathematical basis for controlling pendulum motion in cranes. However, this use case presented additional challenges, notably that the operator needed joystick control for variable speeds, and the rope length changed constantly during operation.

Our team at Motion Australia built on Nachtwey's work. They developed an algorithm that not only controlled sway, but also adapted to changing conditions. The approach broke the motion into carefully calculated segments with intermediate speeds and pauses that canceled pendulum forces.

Effectively, we had to produce a whole series of these intermediate motion profiles and then stitch them together. Imagine you take all of these motion profiles and stick them in a pot, mix them together and get out a hybrid version. That's what allowed us to solve the variable speed and variable height problems.

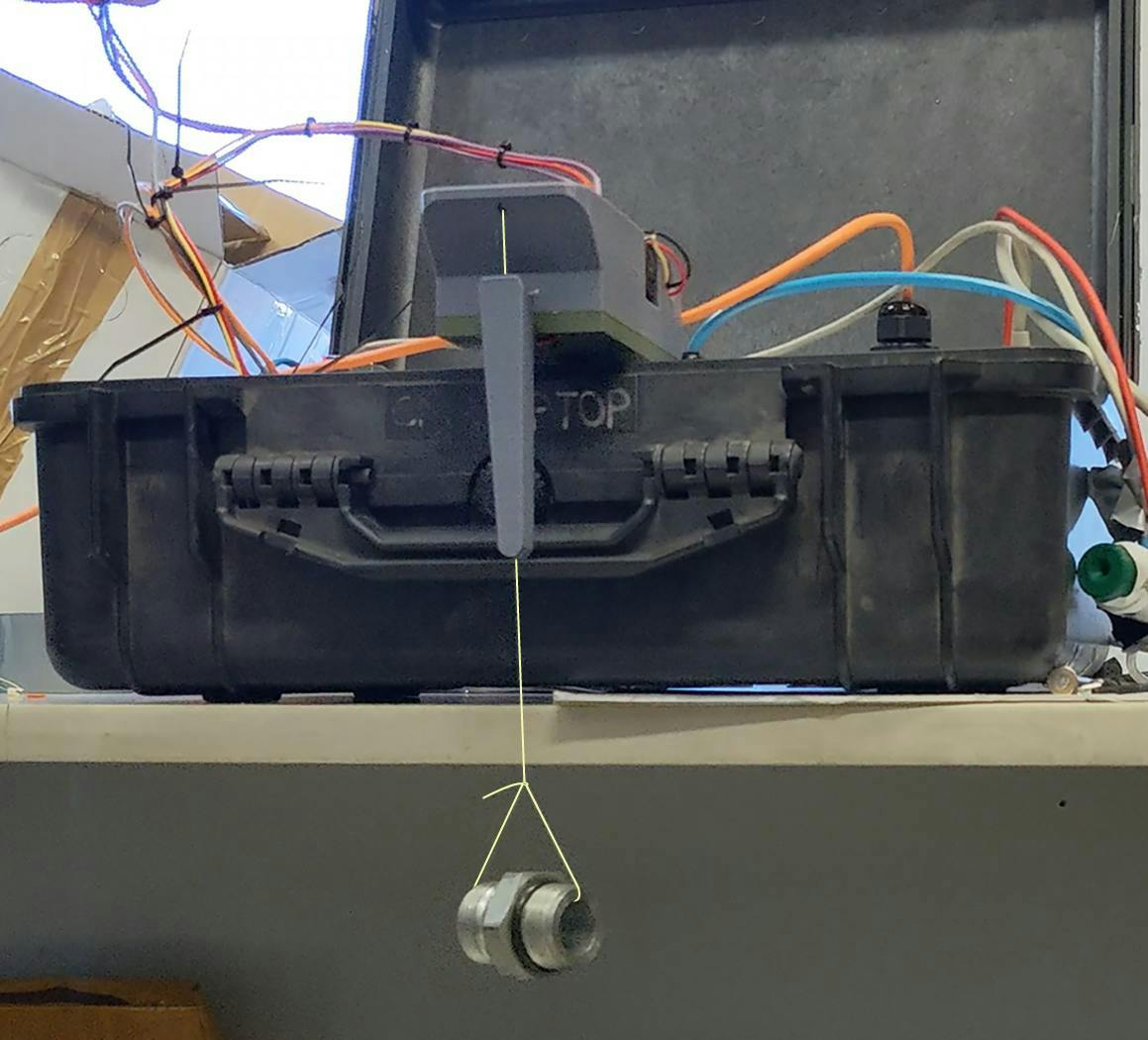

Before risking implementation on the massive port crane, the team constructed a small test rig in the office, a simple motorized suitcase with a suspended weight (Figure 2). Videos demonstrated the dramatic contrast. With standard control, the weight swung wildly. With anti-sway algorithms active, it remained nearly stationary through identical movements.

Deploying precision

For implementation, our team selected Delta’s RMC75E motion controller. This controller offered sufficient memory and processing capability for the sophisticated algorithm, along with Ethernet connectivity to interface with the machine's existing PLC.

We went to the customer and explained how this would be a complex motion control solution. The PLC did not have the mathematical capability or the response speed needed. Delta’s RMC75E was the logical choice. We only needed to control one axis, and the software capability was certainly sufficient to implement this algorithm.

Get your subscription to Control Design’s daily newsletter.

The integration leveraged Delta Motion’s RMCTools software, which made the complex programming task substantially more manageable. RMCTools’ graphical interface simplified the configuration and implementation of the solution’s essential circular buffer architecture. Delta’s intuitive design environment allowed the team to focus on programming the algorithm’s sophisticated mathematics, rather than wrestling with programming details.

The cost of the controller hardware was small compared to the engineering time and effort. Plus, RMCTools is included at no extra cost.

Of course, there were significant challenges. Most Delta controllers typically connect to servo valves that respond within milliseconds with 0.1% accuracy. The port machine used a Swash-plate controlled pump that took up to 2.5 seconds to respond with only 10% accuracy. This required additional tuning and algorithm refinement beyond the core anti-sway function.

Safety concerns also demanded attention. The hydraulic cylinder driving the luffing motion—moving the grab horizontally—had minimal overtravel margin. If the piston were to reach end-of-stroke at high speed, catastrophic structural failure could result.

To prevent this scenario, the team implemented additional safety logic monitoring velocity versus position. If motion exceeded acceptable parameters near endpoints, an emergency stop would instantly trigger.

The software implementation required a circular buffer architecture, essentially predicting up to 20 seconds of motion data in the controller and using that knowledge to modify the present as conditions changed. This allowed real-time adaptation to changing rope length and operator commands while maintaining sway control.

Beyond expectations

During commissioning, our team made gradual refinements to handle both automatic positioning and manual joystick control. The results were immediate. The grab that had previously defied control now moved with precision, stopping directly over target points with barely a wiggle.

The improvement proved so dramatic that the port’s operations manager delivered probably the best, and definitely most colorful, customer testimonial we’ve ever had.

Unlike alternative anti-sway systems that require sensors to measure rope angles, the Delta-based solution works without additional costly hardware. It calculates optimal motion paths mathematically, compensating for both variable speed and changing rope length simultaneously.

Beyond implementation

The port implementation offers crucial lessons for heavy equipment design. The wisdom here would be if you are designing a crane or some device with a suspended load, you must consider load swaying when factoring in the design of the machine. Firstly, it will affect the forces and therefore the structure as well as the drive device. Secondly, if the sway is uncontrolled, it can result in significant damage, or at the very least, significantly slower operation while you wait for the sway to dissipate. But now we’ve shown how to mitigate these issues with motion controllers from Delta Motion.

For the port, the transformation from swinging terror to a predictable, precision machine, all derived from best-of-breed motion control and mathematical algorithms, means more than operational efficiency. It represents millions saved in potential litigation, untold structural damage avoided and faster, more reliable materials delivery for the region’s industries.

About the Author

Ian Duncan

Motion Australia

Ian Duncan is chief engineer at Motion Australia. Contact him at [email protected].