China aims to lead robotics industry with new 5-year plan

The Ministry of Industry and Information Technology (MIIT) in Beijing released a new five-year plan for the robotics industry in China, which focuses on promoting innovation to make China a global leader for robot technology and industrial advancement.

The statistical department of the International Federation of Robotics (IFR) reports about the domestic and foreign engagement on the world's largest market.

“China is by far the biggest robot market in the world regarding annual sales and the operational stock,” said Milton Guerry, IFR president. “IFR´s robot density statistics is a useful indicator of China´s dynamic developments, counting the number of industrial robots per 10,000 employees: China´s robot density in the manufacturing industry currently ranks ninth globally (246 units) - compared to 25th (49 units) just five years ago.”

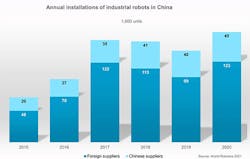

The automation race in China today is mainly catered by foreign robot manufacturers with a combined market share of 73%. With some volatility in the past eight years, this share has been constant. In 2020, installations of robots from abroad - mainly imported from Japan, Korea and Europe - grew strongly by 24% to 123,030 units. This number also includes units produced in China by non-Chinese suppliers. Chinese robot manufacturers mainly deliver to their domestic market, where they held a market share of 27% in 2020 with 45,347 units shipped, IFR reports.

“China released the second five-year development plan for the robotics industry, following 2016-2020,” said Song Xiaogang, executive director and secretary-general of the China Robot Industry Alliance (CRIA). “The plan has great guiding significance for promoting the high-quality development of China's robotics industry during the 14th period. Robots are the key equipment of modern industry. The new five-year plan leads the digital development and intelligent upgrading in China and also helps to promote the global robot technology progress.”