Key Highlights

- The fundamental choice between using a motor starter, which simply connects power to the motor, and a variable-frequency drive (VFD), which controls speed and provides soft start/stop, must be based entirely on the specific application requirements, including speed control needs, budget, energy conservation goals and environmental factors.

- A motor starter is a simpler, less-expensive device used for basic motor operation that relies on contacts for an electrical start and includes overload protection, while a VFD is an advanced device that varies current frequency and/or voltage to allow for precise control over motor speed, acceleration and deceleration.

- While VFDs offer superior control, energy efficiency and diagnostics, their increased cost and potential need for programming and heat management make simpler solutions like a standard or star-delta motor starter viable alternatives when variable speed is not required.

Control systems engineering requires a broad knowledge base of many components. Why? Applications of all shapes, sizes, functionality and needs are brought to machine-builder tables, and automation is requested to provide solutions to manufacturing problems.

Choosing hardware for control systems may be easy but, at best, time-consuming if the application is unknown. Once again, clear requirements are a must.

Knowing what the end goal and the customer needs are will make choosing equipment components easier. Whether the controls engineer is looking at terminal blocks, motors, pressure transducers, protocol benders or human-machine interface (HMI) screens, the objective is the same: What does the customer want? What is the end goal of the application? Motor starters and variable frequency drives (VFDs) are not any different.

System requirements

How do controls engineers discern when to use a motor starter vs. VFD? Let us ask some questions about the application.

- Does your application require speed variation? Is a gentle startup required? Do you need two or more motors to synchronize?

- Now let us ask about budgetary needs. Is the project cost constrained? Does the customer want energy conservation?

- What about the application environment? Will the cabinet for the motor starters or VFDs be outside or inside? What are the space requirements for the application installation?

- Are there reliability concerns? Does the end user want diagnostics? What kind of motor are you trying to start?

- Does the system have a safety braking requirement, as in escalators and elevators?

Thus, how do controls engineers decide which is best for the application? If we define what a motor starter and a VFD are and then apply the answers to these questions, it will be clearer.

Motor starters

A motor starter is an electrical device that provides an electrical start to a motor via contacts controlled by a switch. The contactor opens or closes the contacts, which lets electricity flow or breaks the circuit and stops the motor.

To protect the motor, the starter normally has an overload protection circuit that will reduce the chances of high current making it to the motor in the case of a short. Induction motors work well with starters. The size of the protection circuit on the starter must match the amount of expected inrush for the motor it is paired with. Otherwise, the safety circuit will keep the motor from starting. Starters have different methods of starting. Choosing a method will be based on the application.

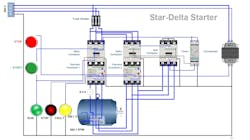

Starter methods include full voltage or across-the-line starter, full voltage reversing starter, multispeed starter, reduced voltage starter, rotor resistance starter, autotransformer starter, star delta starter and soft starter.

Get your subscription to Control Design’s daily newsletter.

A star delta configuration is popular outside of VFDs due to the decrease in voltage across the windings to approximately one-third of the line voltage, compared to a direct-on-line starter, which has a high peak voltage on the motor. Star delta configuration allows the circuit to peak at 80% and then switch to a delta configuration, which allows the motor to run at full voltage and torque.

Star deltas can be an effective solution for reducing starting current and mechanical stress. Some may consider VFDs as starters, as VFDs are an advanced type of soft start.

Variable-frequency drives

VFDs vary the frequency of the supply current and/or can vary the voltage based on the setup of the drive. A VFD consists of a fuse or circuit breaker, a contactor, a rectifier and an inverter. A microcontroller is used on the rectifier side to tell a control circuit how to invert voltages and/or currents before sending the signals to the motor.

The advantages of a VFD are that the startup can be controlled by the circuit board, and this allows smooth acceleration and deceleration based on a profile set up by the VFD configuration. This means the motor life span is increased due to less stress, and the application may be more difficult as a VFD will allow more precise control. Like other motor starters, VFDs may work in forward or reverse motion. Expenses increase with a VFD purchase, and some VFDs need to be programmed. There is also heat dissipation and possible harmonics if the VFD and motor circuit are not tuned to the expected load.

Applications

Starters are used with pumps, fans, conveyor belts, compressors and heating, ventilation and cooling (HVAC) systems. VFDs are used on conveyors that require speed changes—HVAC fans and chillers that need to change motor speeds based on temperature or flows. Pumps that need to change speeds will use a VFD. Industrial mixers will, also.

Elevators and escalators that need to ramp to a set speed and have a controlled stop on a point with a ramp down will also use VFDs. In short, the functionality, energy efficiency, costs, application suitability, speed or torque control, stopping capacity required, motor protection and diagnostics, as well as integration, will dictate whether a controls engineer chooses a motor starter or a VFD.

Conclusion

Is there a better component between a motor starter and a VFD? Many an electrician or engineer could probably argue either side as a viable solution, but saying one solution is better than the other might not always apply. This is why there are in-between solutions to motor starting like the star-delta configuration. VFDs would be a step up in efficiency from the star-delta starter; however, the cost would increase. Once again, a design engineer must look at the scope of the project, expected outcome and the application needs. Using a systems point of view will enable the correct decision to be made in regard to choosing a motor starter or a variable-frequency drive.

About the Author

Tobey Strauch

Arconic Davenport

Tobey Strauch is currently managing brownfield installations for controls upgrades at Arconic Davenport. She has previously worked as principal controls engineer and before getting her bachelor’s in electrical engineering, was a telecommunications network technician. She has 20 plus years in automation and controls. She has commissioned systems, programmed PLCs and robots, and SCADAs, as well as managed maintenance crews. She has a broad mix of mechatronics with process control. She enjoys solving problems with Matlab and Simscape. Contact her at [email protected].