Key Highlights

- Robot integration has matured, shifting the robot from a specialty item to a standardized tool, evidenced by simplified PLC integration via manufacturer-specific software libraries and standardized protocols.

- Engineers must strategically manage the robot cycle time—the time to complete a task—to prevent hindering the overall PLC cycle time, especially when developing modular software architectures for complex automation systems.

- The optimization of robotic workstations should incorporate industrial-engineering practices, treating the robot as a mature tool requiring disciplined design strategies to minimize variance in performance.

Robot cycles could mean more than one thing. The sales cycle is one. Robot news and debate seem to have cooled a bit, but it makes an automation professional wonder how the robot sales cycle is going.

The other robot cycle is the total time it takes for a robot to complete its task. That would be the second robot cycle.

Before that, take a moment to think about how far robots have come in the past 10 years, and ask the question, “Are robots now a tool just like servos or motors or valves?”

Some might rumble that the shine has come off the robots and the collaborative robots (cobots). Everyone has updated their robots, and the robot programming environment has been simplified to the point that we can happily insert robots into our designs anytime and anywhere.

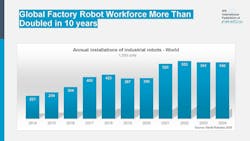

As far as robot sales cycles, global installations of robots reached 542,000 in 2024, according to the International Federation of Robotics' World Robotics 2025 Report, which is double the number of installations 10 years ago and second only to 2022, which saw 553,000 installations. More than half of the world’s robots were deployed in China, and Japan was the second-largest market for industrial robots.

Robotics growth is being pushed by artificial intelligence integration, collaborative robots, humanoid robots and robots as a service. Surgical robots are expected to exceed $25 billion by 2030, according to a report from Meticulous Research.

Logistics and warehousing still are deploying cobots for efficiency improvements. Thus, robots are in the automation arena and still growing. Why ramble on about the economics of robots? Understanding the sales cycle helps to understand the installation requests.

Machine builders are expected to continue to design and install machines using robotic technology. However, robots are not all the buzz for this industrial cycle. Why is that?

In the past 10 years, robots have matured into a tool that allows integrators and machine builders to broaden applications. Robots are delivering high-precision repeatability and real-time feedback. Integration has become easier, as market trends in the cobot world have forced other robot manufacturers to make integration seamless for communications with logic controllers, cameras and safety.

Connections were standardized, and protocols were simplified or added for the purpose of integration with plug-and-play execution. Scalability, flexibility and modularity are sales points for the current robotic product, which means retooling or changing out servos is easier than it was 10 years ago.

What proof is there? If one opens Siemens TIA Portal, you will find the Simatic Robot Integrator Library. Rockwell Automation’s Studio 5000 includes robot integration features. These types of robot libraries are not limited to one brand but offer predefined blocks and motion profiles for many robotic manufacturers. Mitsubishi Electric offers similar tools with MELFA Smart Plus and MELSEC iQ-R series of programmable logic controllers (PLCs).

On the robot side of the house, operators like KUKA and Yaskawa are providing PLCopen-certified interfaces to make PLC compatibility easier with Bosch-Rexroth, Siemens and Rockwell. Universal Robots has the standard robot command interface (SRCI) support for Siemens, which allows programming from the Siemens TIA Portal.

The point to this conversation is not to sell one brand over another, but to provide examples of robot-PLC interfaces that are tools to make robot-PLC integration easier, so machine builders can provide broad solutions for customer application needs.

Get your subscription to Control Design’s daily newsletter.

It's also to demonstrate that the robot has matured. Companies are integrating robots into their software libraries and making tool sets the same way they did for servos and valves and motion control. We should not leave out the advancement of protocols. EtherNet/IP, Profinet, Automation Device Specification and other protocols are contributing to the ease of interface.

With this increased ease in adding robots to applications comes the design responsibility of integrating another type of robot cycle—that would be the robot cycle time or the time it takes for the robot to complete its programmed task. There is a bit of a trend in recent automation circles to program in task timeframes that are modular, instead of the traditional “MAIN” and then calling a bunch of subroutines that run in order. That is still being done, but the complexity of automation systems makes it critical to have the ability to have a function wait and then come to life when needed, but not take up PLC cycle time, which must not be hindered by the robot cycle time.

Should the robot cycle time always be as fast as possible? Some will argue yes, but it depends on the application and on understanding what affects cycle times. Task complexity, robot speed and programming efficiency play roles in robot cycle time. These same ideas affect PLC cycle time. If a conveyor is waiting for a part because a robot took it into a station to perform tasks on the said part, then can the PLC do other activities while waiting on the robot tasks to complete?

These are questions that should be discussed based on software architecture and physical architecture. Industrial-engineering practices, such as a time-and-motion study, work sampling, value stream mapping, standard work, digital twin modeling and line balancing, can be applied to robotic workstations just as easily as they are applied to human workstations. This is another indication that robots are maturing in their lifecycle because now industry is working on optimization.

Think about the seventh axis that people added to allow a robot to move horizontally back and forth while utilizing its other six axes. Think about the seventh axis being used vertically to allow the robot to stack pallets. Think about the changes in safety around robots.

Using a robot as a tool in a PLC-driven application is an everyday part of control design. It’s important to look at using software tools in the PLC development environment to optimize and modularize code driving robots. It’s also ideal to apply industrial-engineering techniques to robot cell development to minimize robot task time.

The enemy of any control system is still variance, and having a mature tool called a robot in the toolbox does not change this. In fact, it adds complication and requires consistent design strategies for robot-PLC integrations. This includes monitoring robot cycle time and deciding when too long or too short is a problem.

About the Author

Tobey Strauch

Arconic Davenport

Tobey Strauch is currently managing brownfield installations for controls upgrades at Arconic Davenport. She has previously worked as principal controls engineer and before getting her bachelor’s in electrical engineering, was a telecommunications network technician. She has 20 plus years in automation and controls. She has commissioned systems, programmed PLCs and robots, and SCADAs, as well as managed maintenance crews. She has a broad mix of mechatronics with process control. She enjoys solving problems with Matlab and Simscape. Contact her at [email protected].

Leaders relevant to this article: